To perform load calculations, identify loads, determine characteristics, calculate demand, apply diversity factors, and consider power factor correction.

Performing Load Calculations for Electrical Systems

Load calculations are essential for designing an electrical system, ensuring the right size of components, and preventing overloads. This article provides a step-by-step guide on how to perform load calculations for an electrical system.

1. Identify Loads

First, make a list of all the electrical loads in the system, including lighting, appliances, motors, and heating and cooling equipment. Consider both continuous and non-continuous loads. Continuous loads operate for 3 hours or more, while non-continuous loads operate for shorter periods.

2. Determine Load Characteristics

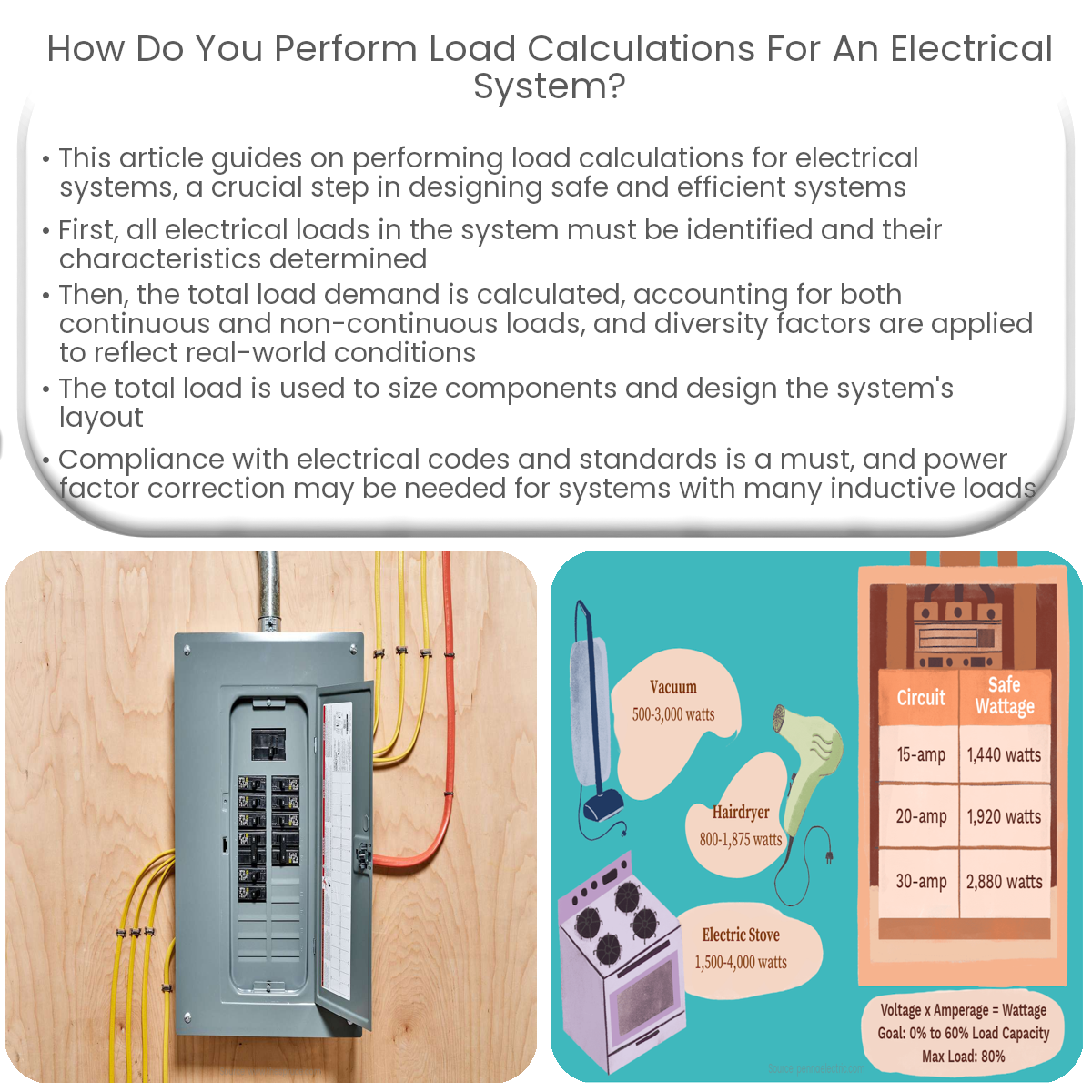

For each load, determine its voltage, current, and power ratings (in watts or VA). These values are typically found on the equipment nameplate or in manufacturer documentation. Also, consider the load type, such as resistive, inductive, or capacitive, as this affects power factor calculations.

3. Calculate Load Demand

Next, calculate the total load demand. Add up the wattage or VA ratings of all continuous loads. For non-continuous loads, apply demand factors specified in electrical codes to account for their intermittent operation. Demand factors reduce the calculated load to a more realistic value, as not all non-continuous loads operate simultaneously.

4. Apply Diversity Factors

Diversity factors account for the fact that not all loads will be operating at maximum capacity simultaneously. These factors are used to adjust the calculated load demand to better represent real-world conditions. Refer to electrical codes, guidelines, or historical data to determine appropriate diversity factors for your system.

5. Calculate Total Load

Multiply the load demand by the diversity factor to obtain the total load. This value is used to size components, such as transformers, conductors, and circuit breakers, as well as to design the system’s overall layout.

6. Consider Power Factor Correction

If the system has a significant number of inductive loads, such as motors or transformers, it may have a low power factor. A low power factor can lead to increased energy costs and reduced system efficiency. In such cases, consider implementing power factor correction measures, such as adding capacitors or installing synchronous condensers.

7. Verify Compliance with Electrical Codes and Standards

Finally, ensure your load calculations and system design comply with applicable electrical codes and standards. These codes ensure the safe and efficient operation of electrical systems and are crucial for avoiding potential hazards.

By following these steps, you can accurately calculate the load for an electrical system and design a safe, efficient, and reliable system that meets the needs of its users.