Explore the world of heat shrink tubing, its working principle, usage, material types, and diverse applications in this comprehensive guide.

Introduction to Heat Shrink Tubing

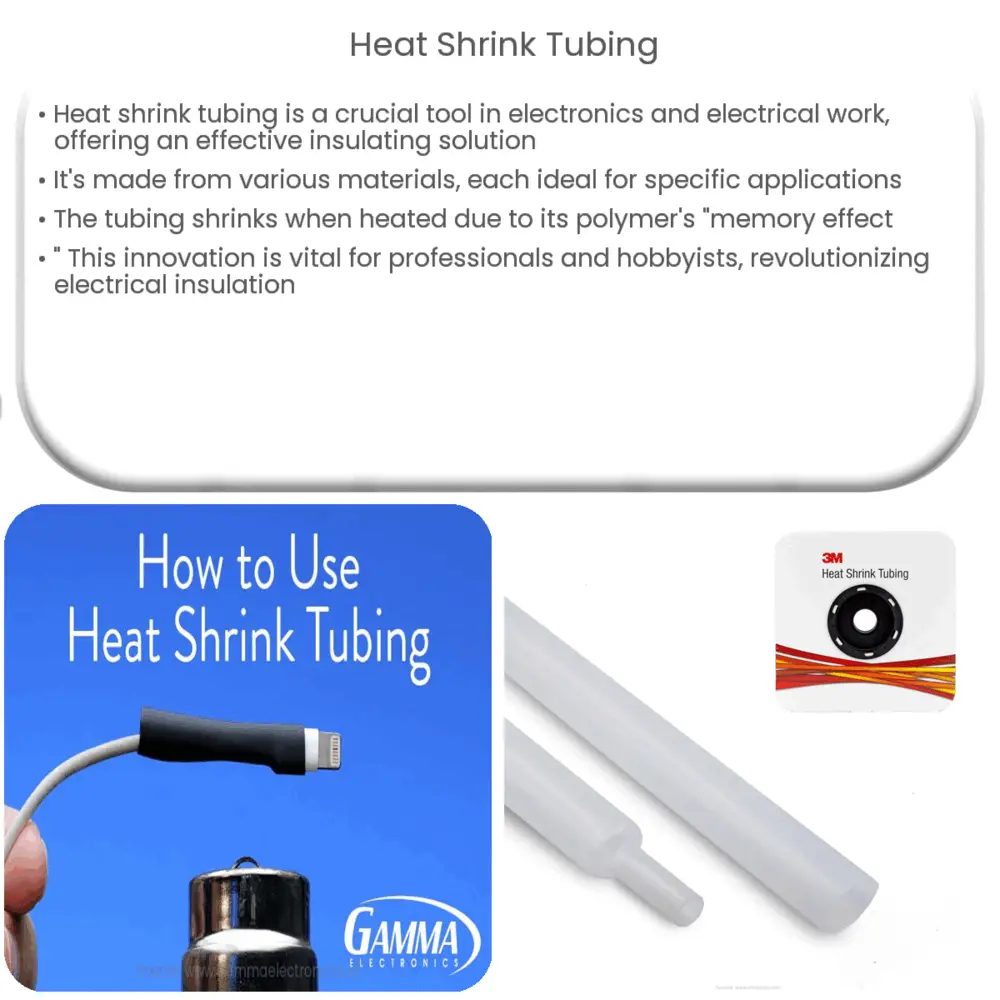

Heat shrink tubing, an essential tool in the world of electronics and electrical work, offers a simple yet effective solution for insulating wires, providing abrasion resistance and environmental protection for stranded and solid wire conductors, connections, joints and terminals in electrical work.

It can be made from various types of materials such as polyolefin, fluoropolymer, PVC, neoprene, silicone elastomer, and Viton. Each type has specific properties that make them ideal for certain applications, giving users a wide range of options to choose from based on their specific needs.

The Working Principle of Heat Shrink Tubing

The principle behind heat shrink tubing is rather fascinating and is primarily a product of modern material science. Essentially, heat shrink tubing is a type of plastic tubing that reduces in size (shrinks) when exposed to heat. The process of how this happens is due to something called the “memory effect” of the polymers used to construct the tubing.

The manufacturing process involves taking a plastic material, heating it, and then stretching it while it’s still hot to the desired diameter. Once cooled, the tubing maintains this stretched size until heat is reapplied, at which point it shrinks back to its original size.

How to Use Heat Shrink Tubing

-

Cut the heat shrink tubing: Begin by cutting the tubing to the desired length. You will want to ensure that it is long enough to cover the entire area needing insulation plus a bit more on each end for full coverage.

-

Slide the tubing onto the wire: Before making any wire connections, slide the heat shrink tubing onto the wire. Remember, it will need to fit over the largest connector that you are using.

-

Make the wire connections: Go ahead and solder or twist your wires together. Make sure they are secure before moving on.

Heat shrink tubing is an innovative solution that has revolutionized the world of electrical insulation. Its ease of use, effectiveness, and versatility make it an indispensable tool for professionals and hobbyists alike.

Continued Use of Heat Shrink Tubing

-

Position the tubing: Once the wire connection is secure, slide the heat shrink tubing over the connection. Be sure to center it so that it covers the connection and a bit of the insulation on either side.

-

Apply heat: Now it’s time to apply heat. A heat gun is typically used for this, but a lighter or hair dryer on high heat can also work. Apply the heat evenly around the tubing, avoiding direct flame if using a lighter. The tubing will begin to shrink and conform to the shape of the wire and connections underneath. Continue until the tubing has fully shrunk and is tightly fitted.

-

Allow the tubing to cool: After the heat shrink tubing has been applied and has shrunk to fit, it’s crucial to let it cool naturally. This will ensure the tubing stays in place and provides the maximum amount of insulation and protection.

Choosing the Right Heat Shrink Tubing

When choosing heat shrink tubing, it’s important to consider several factors. The size, material type, and shrink ratio all play a part in determining the right tubing for your project. The size of the tubing should be chosen based on the diameter of the wires or components it will be covering, while the material type and shrink ratio should be chosen based on the specific environmental requirements of the project.

Common Applications of Heat Shrink Tubing

Heat shrink tubing is used in a variety of applications, including wire harnessing in automobiles, electrical insulation, cable bundling, mechanical protection, strain relief, identification, and even aesthetic enhancement. In industrial settings, heat shrink tubing can be found in aviation and marine environments, electronics manufacturing, telecommunications, and many more.

Conclusion

In conclusion, heat shrink tubing is a highly versatile, essential tool in electrical and electronics work. Its unique shrinking ability when exposed to heat, combined with the vast array of materials it can be made from, allows it to cater to a plethora of applications. From providing electrical insulation and mechanical protection to strain relief and aesthetic enhancement, heat shrink tubing truly stands as a testament to the power of modern material science.