An error occurred. Either the engine you requested does not exist or there was another issue processing your request. If this issue persists please contact us through our help center at help.openai.com.

Introduction to Gas-Filled Temperature Sensors

Temperature sensing has always been a crucial part of many industrial processes, scientific research, and even daily life. Various types of temperature sensors have been developed over the years, each with its unique set of capabilities. One of the most interesting and versatile among them is the gas-filled temperature sensor. This article will delve into the mechanics, usage, and benefits of this remarkable type of sensor.

Understanding Gas-Filled Temperature Sensors

Gas-filled temperature sensors, as the name suggests, employ a gas-filled chamber as their primary sensing element. The core principle of their operation lies in the physical law that gas pressure varies with temperature. When the temperature inside the sensor changes, the gas pressure changes proportionally, allowing the measurement of temperature.

Components and Working Principle

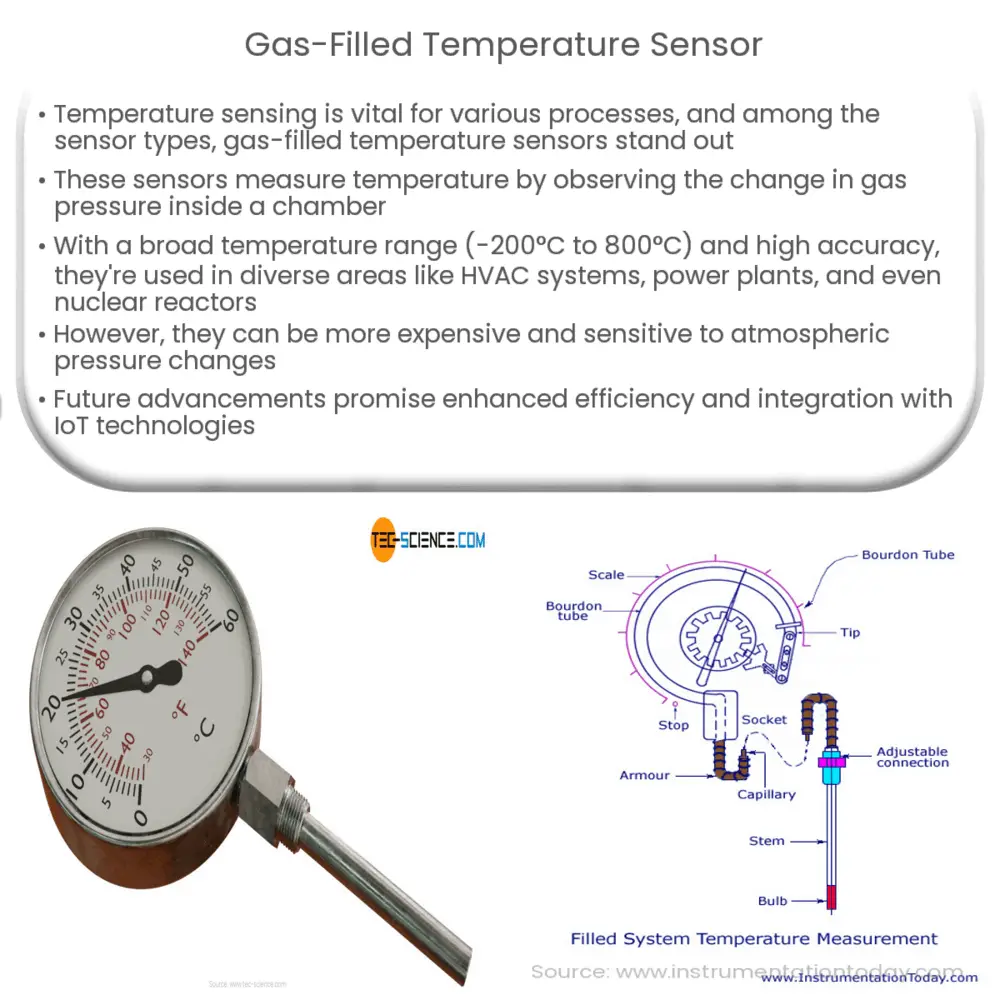

- Gas-filled Bulb: The sensor consists of a gas-filled bulb connected to a Bourdon tube. The bulb is filled with a gas such as helium, nitrogen, or carbon dioxide. When heated or cooled, the gas inside the bulb expands or contracts.

- Bourdon Tube: The Bourdon tube is a sealed, curved tube that deforms or ‘unwinds’ when exposed to increased pressure. The change in the shape of the Bourdon tube is then converted into an electrical signal, which is proportional to the temperature.

- Conversion Mechanism: The change in the shape of the Bourdon tube moves a mechanical linkage connected to a potentiometer or other type of transducer. The transducer converts the mechanical motion into an electrical signal that can be measured and recorded.

Applications of Gas-Filled Temperature Sensors

Gas-filled temperature sensors are widely used in various industries and scientific research due to their high accuracy and broad temperature range. These sensors are ideal for applications where remote temperature sensing is required, such as in HVAC systems, power plants, and process industries. Due to their robustness, they are also used in harsh environments where other types of sensors might fail, such as in high-pressure steam systems or nuclear reactors.

Advantages and Disadvantages of Gas-Filled Temperature Sensors

The primary advantage of gas-filled temperature sensors is their wide temperature range, typically from -200oC to 800oC, which makes them suitable for a plethora of applications. These sensors are also known for their high accuracy and repeatability, ensuring reliable measurements over time.

In addition, gas-filled sensors can measure temperature at a distance, which makes them ideal for remote sensing applications. They are highly durable and can withstand harsh conditions, such as high pressures and corrosive environments.

However, gas-filled temperature sensors also have some limitations. They require a mechanical linkage for converting pressure changes to electrical signals, which can introduce error or delay. The sensor’s performance may also be affected by changes in atmospheric pressure. Finally, these sensors are generally more expensive than other types, which might limit their use in cost-sensitive applications.

Future Prospects

The future of gas-filled temperature sensors is promising, with continual advancements in technology and materials science. Innovations in sensor design and manufacturing processes could lead to more efficient and accurate sensors. Additionally, the integration of these sensors with modern data analytics and Internet of Things (IoT) technologies can open up new possibilities for remote monitoring and predictive maintenance.

Conclusion

In conclusion, gas-filled temperature sensors are a versatile and reliable option for temperature measurement in a wide array of applications. Despite some limitations, their benefits often outweigh the drawbacks, making them an excellent choice for many industries and scientific research. As we look forward to the future, the potential for improvement and innovation in this field is vast, opening up exciting possibilities for further advancements in temperature sensing technology.