Friction motors utilize a flywheel, driving mechanism, and axle to convert stored mechanical energy into motion, often found in toys and small vehicles.

Understanding the Friction Motor: Principles and Applications

Introduction

Friction motors have been a popular choice for powering toys and small vehicles for many years. Their simplicity, affordability, and durability have made them a go-to option for manufacturers and hobbyists alike. In this article, we will delve into the inner workings of friction motors, how they function, and their various applications in today’s world.

Principles of Friction Motors

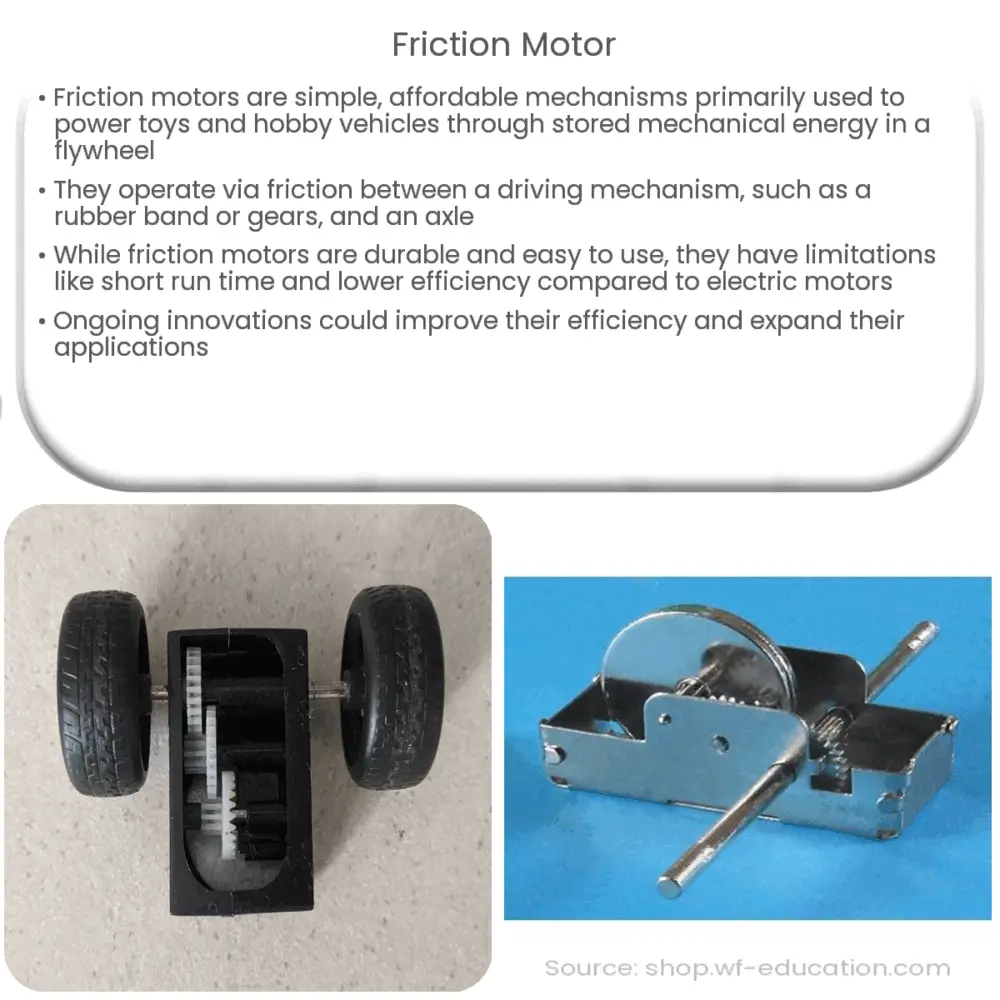

A friction motor is a type of mechanical motor that operates through the force of friction. It typically consists of a flywheel and a driving mechanism, which may be as simple as a rubber band, a small spring, or a more complex gear system. When the flywheel is spun, the friction between the driving mechanism and the wheel’s axle generates enough force to propel the motor forward.

Friction motors are distinct from other types of motors, such as electric motors, which rely on an electrical power source to generate motion. In contrast, friction motors operate solely through mechanical energy, which is stored in the flywheel as it is spun up to speed. This energy is then released gradually as the motor moves, allowing it to maintain a consistent velocity over a short distance.

Components of a Friction Motor

The primary components of a friction motor include the flywheel, the driving mechanism, and the axle. The flywheel is typically made from a heavy, durable material like metal or dense plastic, allowing it to store a significant amount of energy when spun. The driving mechanism, on the other hand, is responsible for transferring the energy from the flywheel to the axle, which then propels the motor forward.

The driving mechanism can take several different forms, depending on the specific design of the friction motor. In some cases, a rubber band or small spring is used to create friction between the flywheel and the axle. In other cases, a gear system is employed to provide a more efficient and controlled transfer of energy. In either case, the driving mechanism is essential for converting the stored energy in the flywheel into forward motion.

Advantages of Friction Motors

There are several key advantages to using friction motors, particularly in small-scale applications such as toys and hobby vehicles. Some of these benefits include:

- Low cost: Friction motors are relatively inexpensive to manufacture, as they do not require any complex electronics or specialized components.

- Simple design: The basic design of a friction motor is quite simple, making it easy to produce and repair.

- Durability: Since friction motors do not rely on electrical components, they are less prone to damage from water, dirt, or other environmental factors, and can provide a longer lifespan.

- Easy to use: Friction motors can be easily activated by simply spinning the flywheel, making them accessible and user-friendly for individuals of all ages.

Limitations of Friction Motors

Despite their advantages, friction motors also have some limitations that may make them less suitable for certain applications:

- Short run time: Due to the reliance on stored mechanical energy, friction motors have a limited run time and require frequent reactivation (spinning the flywheel) to maintain motion.

- Lower efficiency: Friction motors are generally less efficient compared to other motor types, such as electric motors, which can result in reduced performance or speed.

- Limited scalability: Friction motors are best suited for small-scale applications, as their performance tends to diminish when scaled up to larger vehicles or machinery.

Common Applications of Friction Motors

Friction motors are predominantly used in toys and small hobby vehicles. Some popular applications include:

- Toy cars and trucks: Many toy cars and trucks feature friction motors that allow them to move when the flywheel is spun, providing endless entertainment for children.

- Wind-up toys: Friction motors can be found in various wind-up toys, including small robots, animals, and other novelty items that move when the flywheel is activated.

- Hobby vehicles: Friction motors are also used in some small hobby vehicles, such as model airplanes, boats, and cars, providing a simple and affordable means of propulsion.

Future Developments and Potential

While friction motors have been around for many years, there is still potential for improvement and innovation in their design and application. Some possible future developments include:

- Improved efficiency: Advancements in material science and engineering could lead to the development of more efficient friction motors with longer run times and better performance.

- Alternative energy storage: New methods of storing mechanical energy, such as the use of advanced spring systems or even flywheels with magnetic bearings, could potentially enhance the capabilities of friction motors.

- Expanded applications: Although friction motors are mainly used in small-scale applications, advances in technology could make them more viable for larger vehicles or machinery, broadening their potential uses.

Conclusion

Friction motors offer a simple, low-cost, and durable solution for powering toys and small hobby vehicles. Their basic design, which relies on the transfer of mechanical energy stored in a flywheel, has been popular for many years and continues to be a favorite among manufacturers and users alike. While friction motors have their limitations, ongoing research and development could lead to improvements that expand their applications and make them an even more appealing choice in the future.