Explore the world of force sensors, their types, working principles, and applications in our daily lives and future tech trends.

Understanding Force Sensors

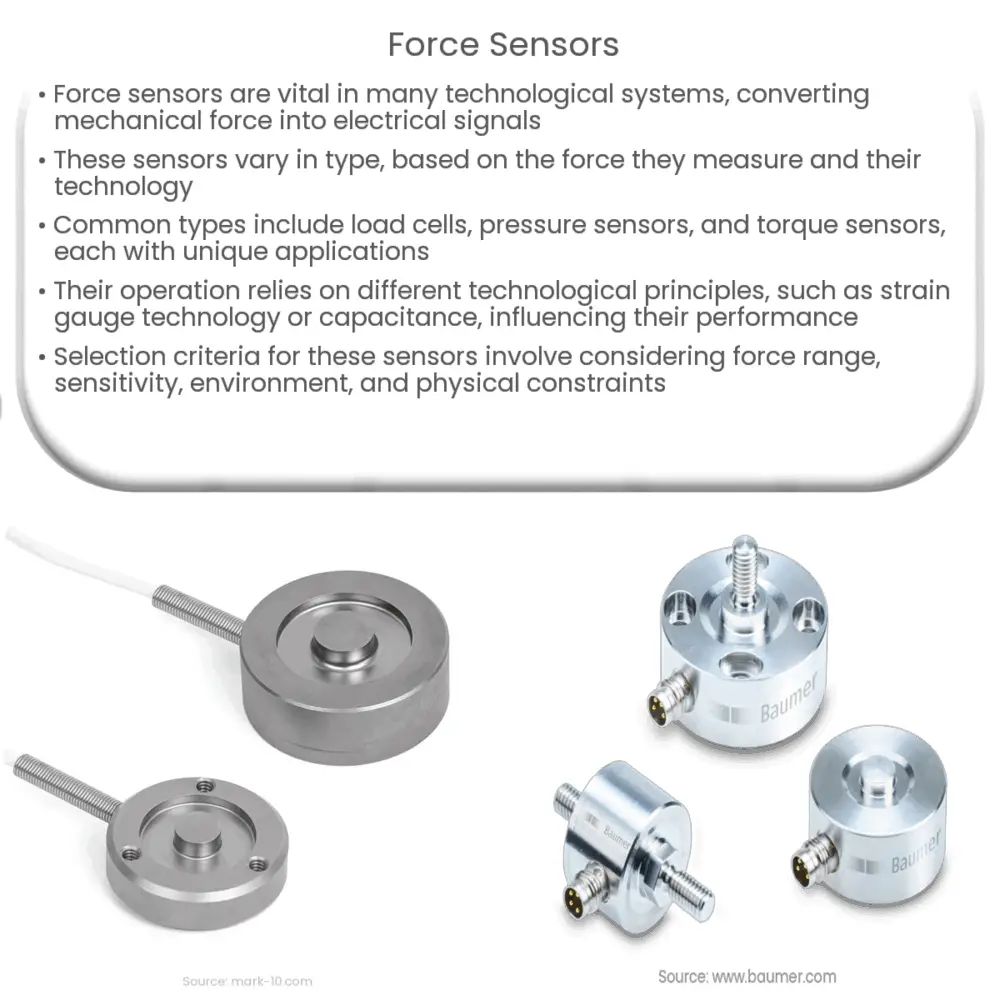

Force sensors are fundamental components of numerous technological systems, ranging from industrial machinery to consumer electronics. Their key function is to convert mechanical force into electrical signals, enabling us to quantify pressure, load, weight, or strain in a given system.

Force sensors are a broad category, encompassing a range of subtypes each with unique characteristics and applications. We can classify these sensors based on the type of force they measure or the technology they employ. Understanding this diversity is key to making an informed selection for a given application.

Types of Force Sensors

Working Principles of Force Sensors

Force sensors can operate on various technological principles, including strain gauge technology, piezoresistance, capacitance, optical, and Hall Effect among others. The choice of technology significantly influences the sensor’s sensitivity, response time, and other performance parameters.

Each of these sensor types and working principles have their specific strengths and trade-offs. Understanding these is critical for selecting the right sensor for a given application, which we will explore in the next section.

Selecting the Right Force Sensor

Choosing the correct force sensor requires an understanding of the application’s demands. Key considerations include the range of force to be measured, the required sensitivity, environmental conditions, response time, and physical constraints such as size and shape.

Force Sensors in Everyday Life

Force sensors have wide-ranging applications in our daily lives. In the automotive industry, they are used in braking systems and airbag deployments. In healthcare, they help in monitoring vital signs and are integral to innovative devices like blood pressure monitors. In the world of gaming, force sensors enhance user interaction by responding to the amount of pressure exerted on buttons or touch screens.

Future Trends

With the advent of IoT (Internet of Things), the demand for force sensors is likely to grow. As devices become smarter and more interconnected, the need to accurately measure force in various applications will drive advancements in sensor technology. Whether it’s in autonomous vehicles, smart homes, or wearable devices, force sensors will continue to play a crucial role.

Conclusion

In conclusion, force sensors are integral components in a myriad of applications, from industrial machinery to wearable tech. Understanding the types of force sensors, their working principles, and key selection criteria is vital for leveraging their capabilities in various fields. As technological advancements continue, we can expect these versatile devices to become even more crucial in our increasingly interconnected world.