Float level sensors accurately measure liquid levels in tanks and containers, offering simplicity, reliability, and cost-effectiveness.

Understanding Float Level Sensors: An Essential Tool for Liquid Level Measurement

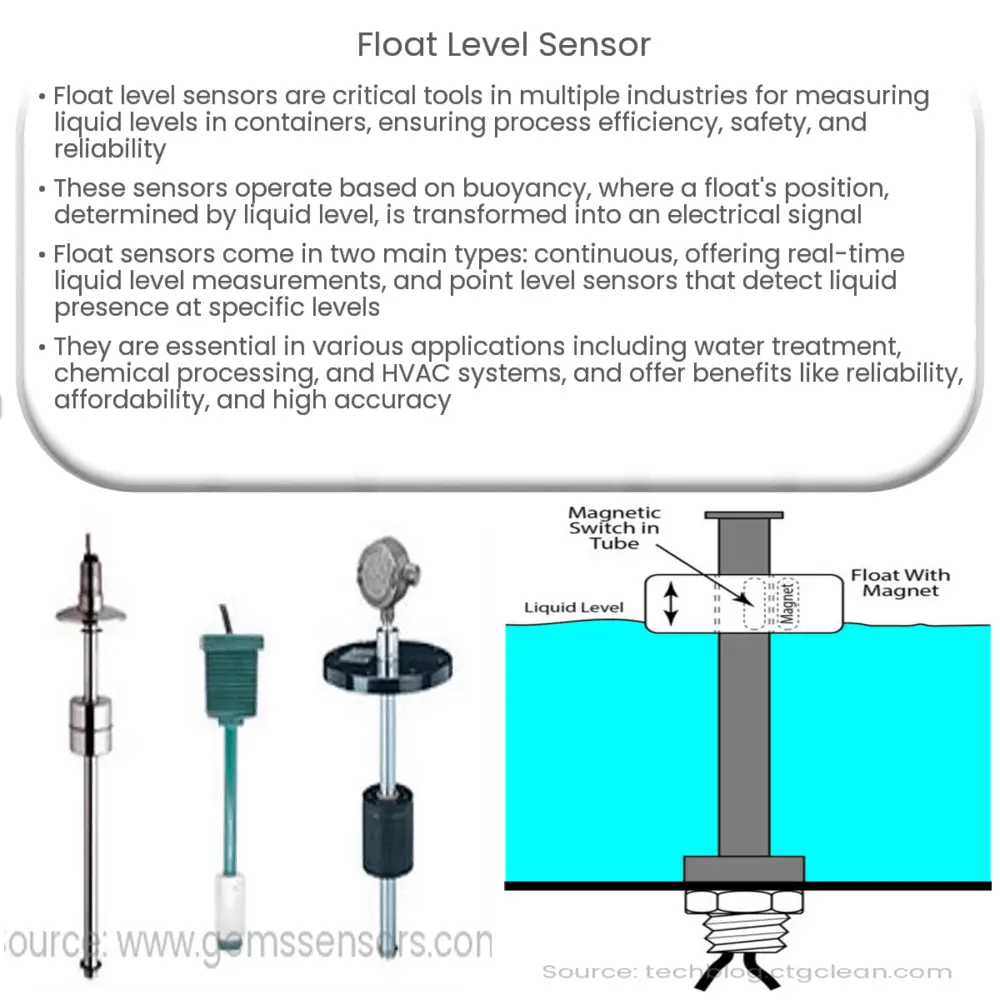

Float level sensors are widely used in various industries to measure the level of liquids in tanks, vessels, and other containers. These sensors play a crucial role in ensuring the efficiency, safety, and reliability of different processes. In this article, we will explore the working principle, applications, and advantages of float level sensors.

Working Principle of Float Level Sensors

Float level sensors rely on the buoyancy principle to determine the liquid level. As the name suggests, a float is the central component of the sensor. This float, which is less dense than the liquid it’s measuring, remains partially submerged in the liquid. When the liquid level changes, the float moves up or down accordingly. The position of the float is then converted into an electrical signal, which can be used to display the liquid level or trigger alarms and other control actions.

There are two main types of float level sensors: continuous and point level sensors. Continuous float level sensors provide real-time, continuous measurement of the liquid level, while point level sensors indicate the presence or absence of liquid at a specific level.

Continuous Float Level Sensors

Continuous float level sensors typically use a magnetic float coupled with a sensing element to provide continuous level measurement. The most common sensing elements include:

- Magnetostrictive: These sensors use a wire or rod made of a magnetostrictive material, which changes its shape under the influence of a magnetic field. The position of the float generates a magnetic field that causes a change in the wire’s shape, which is then translated into an electrical signal proportional to the liquid level.

- Reed Switch: Reed switches are sealed in a glass tube and consist of two magnetic contacts. When the magnetic float moves along the tube, it activates the reed switches, which then provide a voltage output proportional to the liquid level.

- Resistance Tape: This sensing element consists of a tape with a resistive material, such as a conductive plastic or a thin metal film. As the float moves up or down, it changes the resistance of the tape, which is then translated into an electrical signal corresponding to the liquid level.

Point Float Level Sensors

Point float level sensors, also known as float switches, are used to detect the presence or absence of liquid at a specific level. They can be used to trigger alarms, pumps, or other control actions. Point float level sensors typically use a single or multiple reed switches that are activated by a magnetic float when the liquid reaches the desired level. These sensors can be installed vertically or horizontally, depending on the application requirements.

Applications of Float Level Sensors

Float level sensors are versatile and can be used in a wide range of industries and applications, including:

- Water and wastewater treatment

- Chemical processing

- Food and beverage production

- Oil and gas industry

- Pharmaceutical manufacturing

- Marine and offshore applications

- Heating, ventilation, and air conditioning (HVAC) systems

Advantages of Float Level Sensors

Float level sensors offer several benefits that make them an attractive choice for various liquid level measurement applications:

- Simple and Reliable: Float level sensors have a straightforward operating principle and few moving parts, which contribute to their reliability and low maintenance requirements.

- Wide Range of Materials: Floats and sensor components can be made from a variety of materials, making them suitable for use with various types of liquids, including corrosive and aggressive media.

- Cost-effective: Float level sensors are generally more affordable than other types of level sensors, making them an economical choice for many applications.

- Easy to Install and Configure: Installation and configuration of float level sensors are relatively simple, reducing the need for extensive technical expertise or specialized tools.

- High Accuracy: Continuous float level sensors can provide high accuracy level measurements, making them suitable for applications that require precise liquid level monitoring.

Selecting the Right Float Level Sensor

To choose the best float level sensor for a specific application, consider the following factors:

- Measurement Range: Determine the required measurement range based on the maximum and minimum liquid levels in the container.

- Accuracy and Resolution: Consider the level of accuracy and resolution needed for the application. Continuous float level sensors typically offer higher accuracy than point level sensors.

- Temperature and Pressure: Evaluate the operating temperature and pressure conditions of the application, as these factors can affect the performance and longevity of the sensor.

- Chemical Compatibility: Ensure that the materials used in the float and sensor components are compatible with the liquid being measured.

- Mounting and Installation: Consider the available space and mounting options for the sensor, as well as any requirements for easy access or maintenance.

- Output and Connectivity: Choose a sensor with the appropriate output and communication options for your system, such as analog or digital signals and various communication protocols.

Conclusion

Float level sensors are an essential tool for liquid level measurement in various industries and applications. With their simple operating principle, wide range of materials, and cost-effective nature, float level sensors continue to be a popular choice for monitoring and controlling liquid levels. By understanding the working principles, applications, and advantages of float level sensors, and considering key factors when selecting a sensor, you can ensure the best possible solution for your liquid level measurement needs.