Fiber-optic force sensors use light to measure force, providing high sensitivity, EMI immunity, and resistance to harsh conditions.

Fiber-Optic Force Sensors: Revolutionizing Sensing Technology

Force sensors are critical components in numerous industries and applications, ranging from manufacturing to healthcare. Over the years, sensing technology has undergone significant advancements to meet the growing demand for accurate and reliable measurements. One such breakthrough is the development of fiber-optic force sensors, which offer a host of advantages over traditional sensing methods. In this article, we will explore the underlying technology, benefits, and applications of fiber-optic force sensors.

Understanding Fiber-Optic Force Sensors

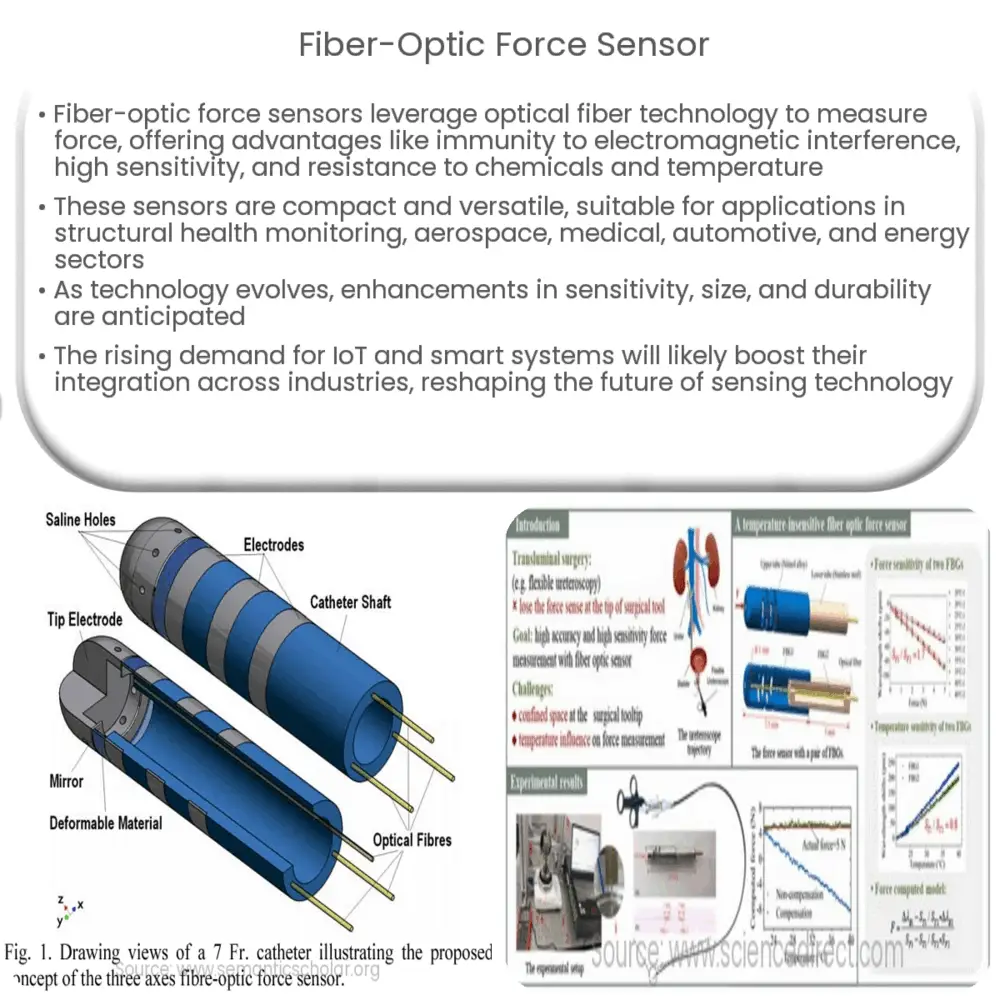

Fiber-optic force sensors utilize the principles of optical fiber technology to measure force, pressure, or strain. These sensors typically consist of an optical fiber embedded within a sensing element, such as a diaphragm or a cantilever. When a force is applied to the sensing element, it causes a deformation or displacement, which in turn alters the optical properties of the fiber. This change can be detected by monitoring the light transmission through the fiber, allowing for the measurement of the applied force.

Several techniques are employed to detect the changes in the optical properties of the fiber, including intensity-based, interferometric, and fiber Bragg grating (FBG) methods. Intensity-based sensors measure the changes in the intensity of the light transmitted through the fiber, while interferometric sensors rely on the interference of light waves to detect the changes. FBG sensors, on the other hand, use the wavelength of light reflected by the grating inscribed in the fiber core to measure the applied force.

Benefits of Fiber-Optic Force Sensors

Compared to traditional force sensing technologies, fiber-optic force sensors offer several advantages that make them attractive for various applications:

- Immunity to Electromagnetic Interference (EMI): Fiber-optic sensors are immune to EMI and radio frequency interference (RFI) due to their dielectric nature. This feature makes them ideal for use in environments with high electromagnetic noise, such as power plants and aerospace applications.

- High Sensitivity and Resolution: Fiber-optic force sensors can achieve high sensitivity and resolution, enabling them to detect minute changes in force or pressure. This precision is particularly useful in applications where accurate measurements are critical, such as medical diagnostics and structural health monitoring.

- Chemical and Temperature Resistance: Optical fibers are resistant to a wide range of chemicals and can operate in extreme temperature conditions, making them suitable for harsh environments, such as oil and gas exploration or chemical processing facilities.

- Compact and Lightweight: Fiber-optic force sensors are compact and lightweight, allowing for easy integration into existing systems and reducing the overall weight of the system. This is especially beneficial in aerospace and automotive applications, where weight reduction is a key consideration.

Applications of Fiber-Optic Force Sensors

The unique benefits of fiber-optic force sensors make them suitable for a diverse array of applications, including:

- Structural Health Monitoring: Fiber-optic force sensors can be used to monitor the structural integrity of buildings, bridges, and other infrastructure, detecting early signs of damage or degradation. By continuously monitoring the applied forces and strains, these sensors can help identify potential issues before they become critical, ensuring the safety and longevity of the structure.

- Aerospace: In aerospace applications, fiber-optic force sensors can measure various parameters, such as pressure, temperature, and strain, in aircraft systems and components. Their immunity to EMI and lightweight design make them ideal for use in this demanding environment.

- Medical: Fiber-optic force sensors play a vital role in medical diagnostics and treatment, such as measuring intraocular pressure in glaucoma patients, monitoring blood pressure, and detecting force during minimally invasive surgical procedures. Their high sensitivity and biocompatibility make them well-suited for these applications.

- Automotive: In the automotive industry, fiber-optic force sensors can be used for monitoring tire pressure, measuring engine performance parameters, and assessing structural integrity during crash tests. Their compact size and resistance to harsh conditions make them a valuable asset in this field.

- Energy: The oil and gas industry, as well as renewable energy systems, can benefit from fiber-optic force sensors for monitoring pressure, temperature, and strain in various components and structures. Their resistance to chemicals and high temperature make them ideal for these challenging environments.

Future Outlook

As technology advances, we can expect to see further improvements in fiber-optic force sensors, including enhanced sensitivity, reduced size, and increased durability. The development of new sensing techniques and materials, such as nanomaterials and specialty optical fibers, may lead to even more versatile and robust sensors that can be tailored to specific applications.

Moreover, the growing demand for smart systems and the Internet of Things (IoT) is likely to drive the integration of fiber-optic force sensors into various industries, enabling real-time monitoring and control of critical parameters. As a result, fiber-optic force sensors will continue to play a significant role in shaping the future of sensing technology and providing solutions for a wide range of applications.

Conclusion

Fiber-optic force sensors have revolutionized the sensing technology landscape, offering numerous advantages over traditional methods, including immunity to electromagnetic interference, high sensitivity and resolution, chemical and temperature resistance, and compact design. Their diverse applications range from structural health monitoring and aerospace to medical diagnostics and energy systems. As technology continues to advance, we can expect to see further improvements and wider adoption of fiber-optic force sensors in various industries, ultimately contributing to a smarter and safer world.