Explore the importance of ESD Workstation Monitors in electronics manufacturing and learn how to choose and implement them effectively.

Introduction to ESD Workstation Monitors

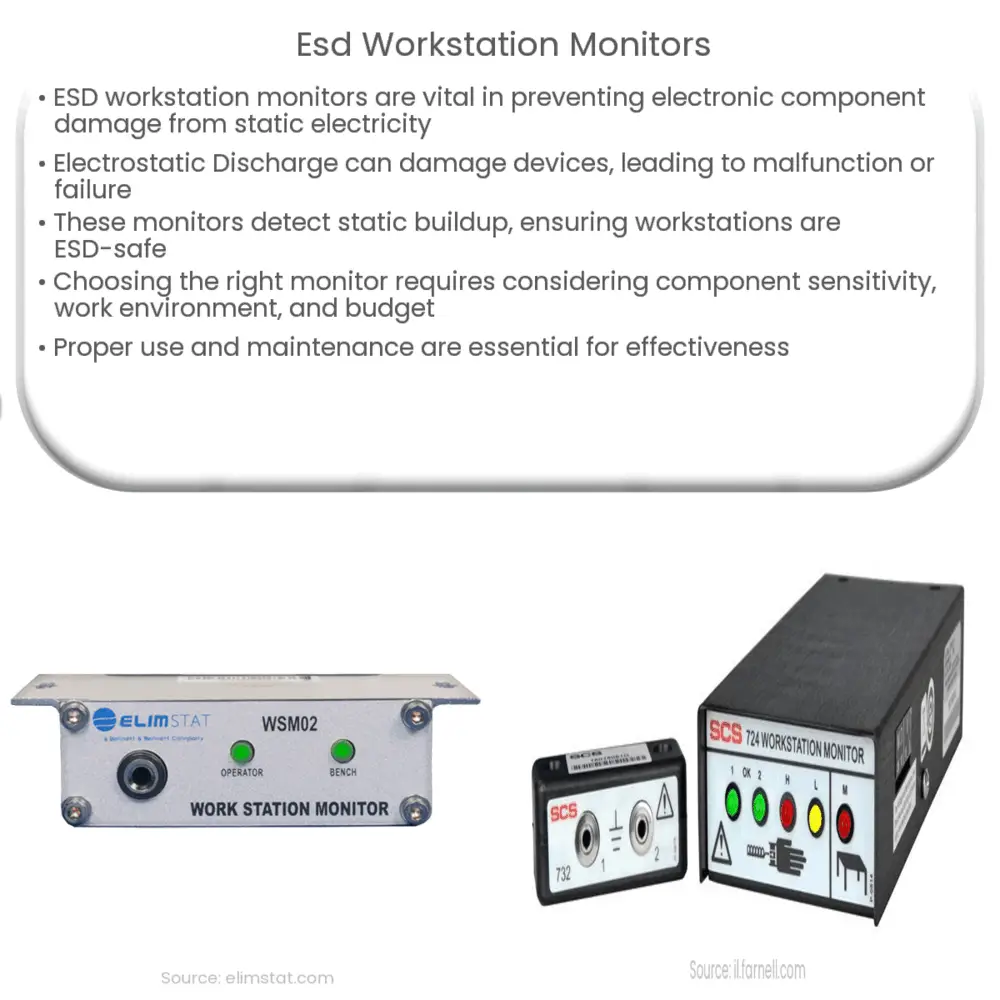

Electrostatic discharge (ESD) workstation monitors are an essential part of many industries, especially in the electronics manufacturing and repair sectors. They play a crucial role in preventing damage to electronic components that can be caused by static electricity. In this article, we will delve into what ESD workstation monitors are, why they are important, and how they work.

Understanding Electrostatic Discharge (ESD)

ESD refers to the sudden flow of electricity between two objects caused by contact, an electrical short, or dielectric breakdown. This flow of electricity can cause immediate or latent damage to an electronic device. The issue arises when the electrostatic discharge is large enough to affect the operation of the internal circuitry, leading to device malfunction or complete failure.

The Importance of ESD Workstation Monitors

The sensitive nature of electronic components makes them susceptible to damage from relatively low voltages. Since static electricity can build up unnoticed on workers or workstations, ESD workstation monitors become a crucial safety measure. These monitors help keep a check on static buildup and ensure that the workstation remains ESD-safe.

- Protection of Components: The primary function of ESD workstation monitors is to protect electronic components from static-induced damage.

- Improved Product Quality: By ensuring components are not damaged during manufacture or repair, the overall product quality is enhanced.

- Cost Savings: By reducing component failure, these monitors can lead to significant cost savings in terms of reduced rework and warranty claims.

How ESD Workstation Monitors Work

ESD workstation monitors work by continuously checking the grounding integrity of the workstation. This includes the worker, mat, tools, and any other connected items. When an ESD event occurs, it is immediately detected by the monitor and an alarm is triggered, notifying the user of the potential hazard.

Types of ESD Workstation Monitors

ESD workstation monitors come in various forms and functionalities. Here are a few common types:

- Continuous Monitors: These monitors offer real-time continuous monitoring of the workstation, ensuring maximum ESD protection.

- Event Detectors: These monitors detect and notify the user of any ESD events that occur.

Each type of monitor offers unique advantages and choosing the right one depends on the specific requirements of your ESD control plan.

Choosing the Right ESD Workstation Monitor

Selecting an ESD workstation monitor involves taking into consideration several factors. Here are a few points to consider:

- Level of Sensitivity: Different electronic components have varying levels of sensitivity to ESD. The more sensitive the components you’re working with, the more rigorous your monitoring system needs to be.

- Work Environment: The conditions of your work environment, such as the level of humidity, can influence static buildup. Environments with low humidity may require more vigilant monitoring.

- Budget: The cost can vary greatly between different types of monitors. Balancing the needs of your ESD control plan with your budget will help you choose a monitor that provides adequate protection without being overly expensive.

Implementing ESD Workstation Monitors

After choosing an appropriate ESD workstation monitor, it is important to properly implement and use it. Regular checks and maintenance of the monitor are necessary to ensure it is functioning correctly. Workers should also be adequately trained in responding to alarms and taking necessary action when an ESD event is detected.

Conclusion

ESD workstation monitors play a pivotal role in protecting electronic components from potential damage caused by electrostatic discharge. They not only help maintain the quality of the product but also contribute to significant cost savings. While choosing the right monitor, it’s important to consider factors such as component sensitivity, work environment, and budget. Proper implementation and regular maintenance of these monitors are also crucial in ensuring an ESD-safe work environment. With a robust ESD control plan in place, organizations can significantly mitigate the risks associated with electrostatic discharge and ensure the longevity and reliability of their electronic products.