Explore the importance of ESD safe workbenches in protecting electronics, learn how they function, and understand their future relevance.

Understanding ESD Safe Workbenches

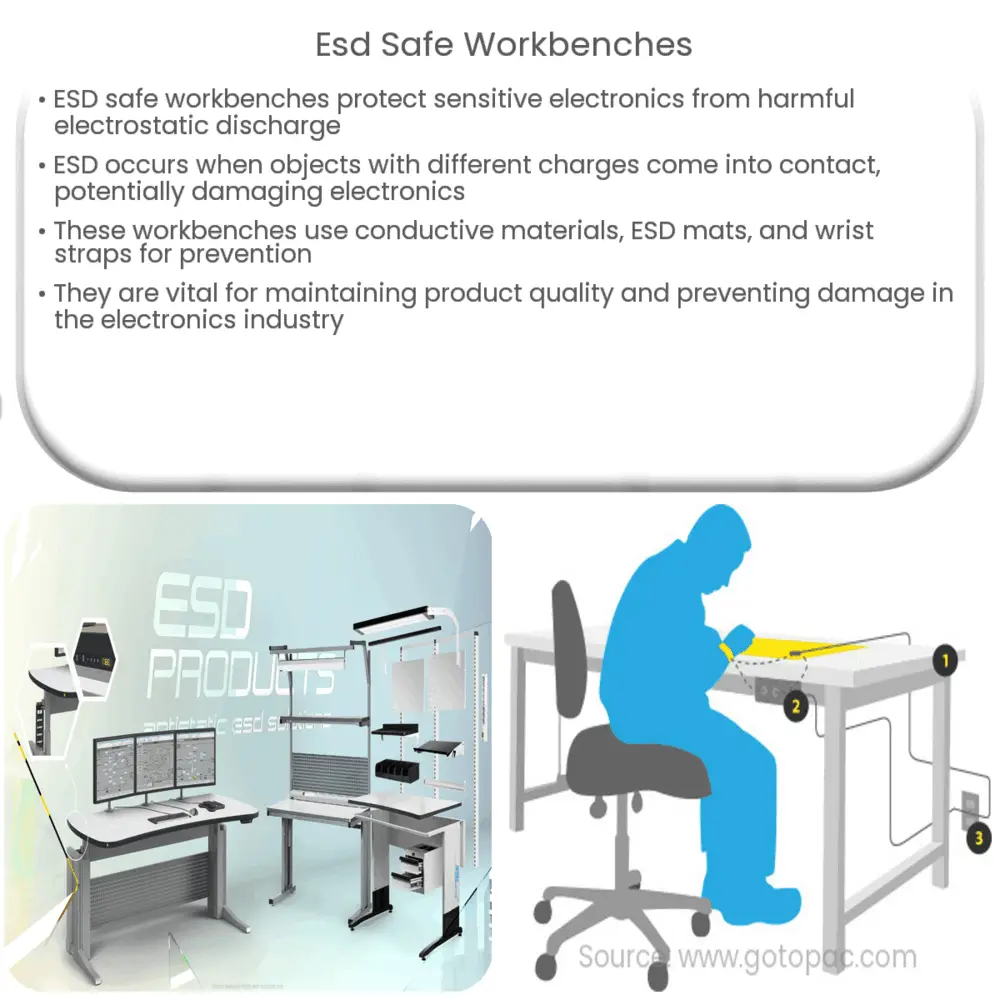

Electrostatic Discharge (ESD) can significantly harm or even destroy sensitive electronics and components. As such, creating an environment that mitigates this risk is crucial in many industries. The solution? ESD safe workbenches. These specialized workstations are carefully designed and constructed to prevent ESD, ensuring the safety of both the electronic components and the operators.

How Does ESD Affect Electronics?

Firstly, it’s essential to understand how ESD can damage electronics. Essentially, ESD occurs when two objects with different electrical charges come into contact. When this happens, there is a sudden flow of electricity from one object to the other. This rapid transfer of electrostatic charge can result in a high voltage peak that can damage or destroy sensitive electronic components.

The Role of an ESD Safe Workbench

An ESD safe workbench plays a crucial role in preventing electrostatic discharge. It achieves this through a combination of careful design and the use of specific materials. Let’s break this down further:

- Conductive materials: The surfaces of an ESD safe workbench are usually made from conductive materials. These materials allow for the equal distribution of charges, preventing the buildup of static electricity.

- ESD mats: These mats are typically placed on the workbench surface. They serve to provide a path for static charge to ground, helping to prevent ESD events.

- ESD wrist straps: These straps are used by operators to prevent the accumulation of static electricity on their bodies. The wrist strap is connected to the workbench and acts as a grounding mechanism, ensuring any potential static charge is safely dissipated.

The Importance of ESD Safe Workbenches

ESD safe workbenches are a critical component of an effective ESD control program. They provide a safe and controlled environment for the handling and assembly of sensitive electronic components. Not only do they help to prevent damage and waste, but they also play a role in maintaining the quality of electronic products. In an increasingly digital world, the importance of these workbenches cannot be understated.

As we move forward into the realm of more advanced and delicate electronics, ESD protection becomes even more crucial. Consequently, the demand for ESD safe workbenches is set to increase significantly in the future. Stay tuned for a deeper dive into the specifics of ESD safe workbenches in the next section of this article.

Selecting the Right ESD Safe Workbench

When it comes to choosing an ESD safe workbench, several factors need to be considered to ensure optimal ESD protection:

- Size and Design: The workbench should be large enough to accommodate the tasks and components involved. The design should also facilitate ergonomic working to reduce operator fatigue and improve productivity.

- Materials: As previously mentioned, the materials used in the construction of the workbench are crucial. They should be both durable and conductive, to ensure long-lasting performance and effective ESD protection.

- Additional ESD Control Measures: An ESD safe workbench should incorporate additional ESD control measures, such as ESD mats and wrist straps. However, these measures should be supplemented by other ESD control strategies, including the use of ESD-safe clothing and footwear, ESD-safe storage bins, and an ESD-safe environment.

Maintenance of an ESD Safe Workbench

Just as important as selecting the right workbench is maintaining it. Regular cleaning with ESD-safe cleaning products is essential to prevent the buildup of static charge. Furthermore, regular inspections should be carried out to ensure all components are functioning correctly and that there is no visible wear or damage that could compromise the ESD-safe properties of the workbench.

The Future of ESD Safe Workbenches

As technology continues to advance and electronic components become more sensitive, the importance of ESD safe workbenches is only set to increase. Innovations in material science and design are continually being made to improve ESD protection, leading to more effective and safer workbenches. As we look towards the future, ESD safe workbenches will continue to play an increasingly pivotal role in ensuring the safety and reliability of electronic components.

Conclusion

In conclusion, ESD safe workbenches are vital to protecting sensitive electronic components from the harmful effects of electrostatic discharge. By utilizing conductive materials and incorporating additional ESD control measures, these workbenches provide a safe environment for the handling and assembly of electronic parts. Furthermore, their importance in maintaining product quality and reducing waste makes them a fundamental requirement in electronics-related industries. As we continue to move into an increasingly digital era, ESD safe workbenches will undoubtedly play an even more critical role in our technological advancements.