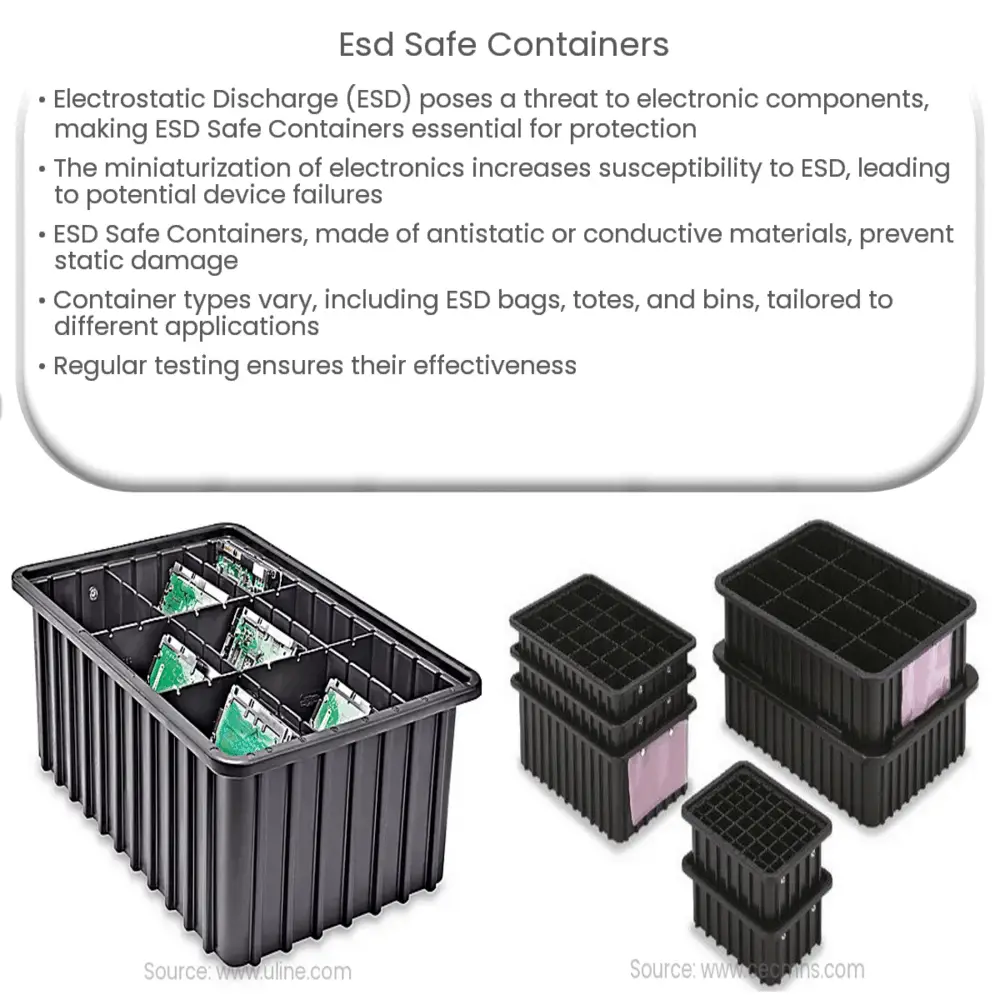

Explore the importance of ESD Safe Containers in protecting sensitive electronic components from electrostatic discharge, types of these containers, and their selection factors.

Understanding ESD Safe Containers

Electrostatic Discharge (ESD) is a sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. In our high-tech world, this can pose a significant threat to electronic components, potentially causing damage or even total failure. To mitigate this risk, ESD Safe Containers are utilized in many industries, providing a vital layer of protection against electrostatic damage.

The Need for ESD Safe Containers

With the miniaturization of electronic components, their susceptibility to ESD damage has drastically increased. ESD can cause latent or catastrophic failures. Latent failures are deceptive because they don’t immediately render the device useless. Instead, they shorten the life of the product, leading to untimely failures down the line. Catastrophic failures, on the other hand, completely incapacitate the device immediately. Therefore, it becomes crucial to use ESD Safe Containers to prevent such situations.

Working Principle of ESD Safe Containers

ESD Safe Containers, often made from antistatic or conductive materials, offer an effective means of ESD prevention. These materials reduce the buildup of static electricity by allowing the charges to flow to ground more readily. This flow ensures that any static charge developed on the surface of the containers doesn’t harm the electronic components inside.

- Antistatic Materials: These are typically insulative or resistive materials that have been modified to reduce the charge generation. They do this by increasing the rate at which charge dissipates.

- Conductive Materials: These materials “conduct” electricity, allowing electric charges to move freely across their surfaces or through their volume.

Types of ESD Safe Containers

The design and type of ESD Safe Containers can vary based on the requirements of the application. They can range from ESD safe bags, ESD totes, ESD bins, ESD storage boxes, and ESD trays.

- ESD Safe Bags: These are commonly used to store and transport static-sensitive electronic components. They are typically made of a slightly conductive plastic, which allows electrostatic charges to leak off the surface gradually.

(End of Part 1)

- ESD Totes: These are larger containers ideal for transporting or storing larger or multiple ESD-sensitive items. They often incorporate conductive materials to maintain a static-safe environment.

- ESD Bins: Bins are used for storing larger components or assemblies. Like other ESD safe containers, these also reduce the risk of ESD damage.

- ESD Storage Boxes: These are often used in workstations for storing ESD sensitive items temporarily. They are designed to shield the contents from ESD and sometimes from physical damage as well.

- ESD Trays: Trays are useful for organizing static-sensitive components during assembly or inspection processes. They are often made with conductive materials and can be stacked to save space.

Factors to Consider While Selecting ESD Safe Containers

When selecting ESD Safe Containers, a few essential aspects need to be considered. These include the type of ESD sensitive item, the environment where the items are to be used or stored, the conductivity of the material, and the durability of the container.

The Importance of Regular Testing and Verification

Even after implementing ESD Safe Containers, it’s vital to conduct regular testing and verification. This ensures the ongoing effectiveness of the ESD protection strategy. Factors like humidity, temperature, and wear and tear can impact the performance of ESD Safe Containers over time.

Conclusion

In conclusion, ESD Safe Containers play a critical role in preserving the lifespan and functionality of sensitive electronic components. They are a practical and efficient solution to protect such components from potential electrostatic discharge damage. By understanding the different types of ESD Safe Containers and factors to consider when selecting these containers, industries can substantially mitigate the risks associated with ESD. Regular testing and verification of these containers ensure they maintain their protective qualities, further strengthening the overall ESD protection strategy.

(End of Part 2)