Explore the crucial role of ESD Ionizers in mitigating electrostatic discharge, their diverse types, working principles, applications, and maintenance tips.

Understanding ESD Ionizers

Electrostatic discharge (ESD) is a rapid, spontaneous transfer of electrostatic charge induced by a high electrostatic field. It occurs when differently-charged objects are brought close together or even come into direct contact. The phenomenon is common in many industrial environments and can cause severe damage to electronic equipment. This is where ESD ionizers come into play.

The Role of ESD Ionizers

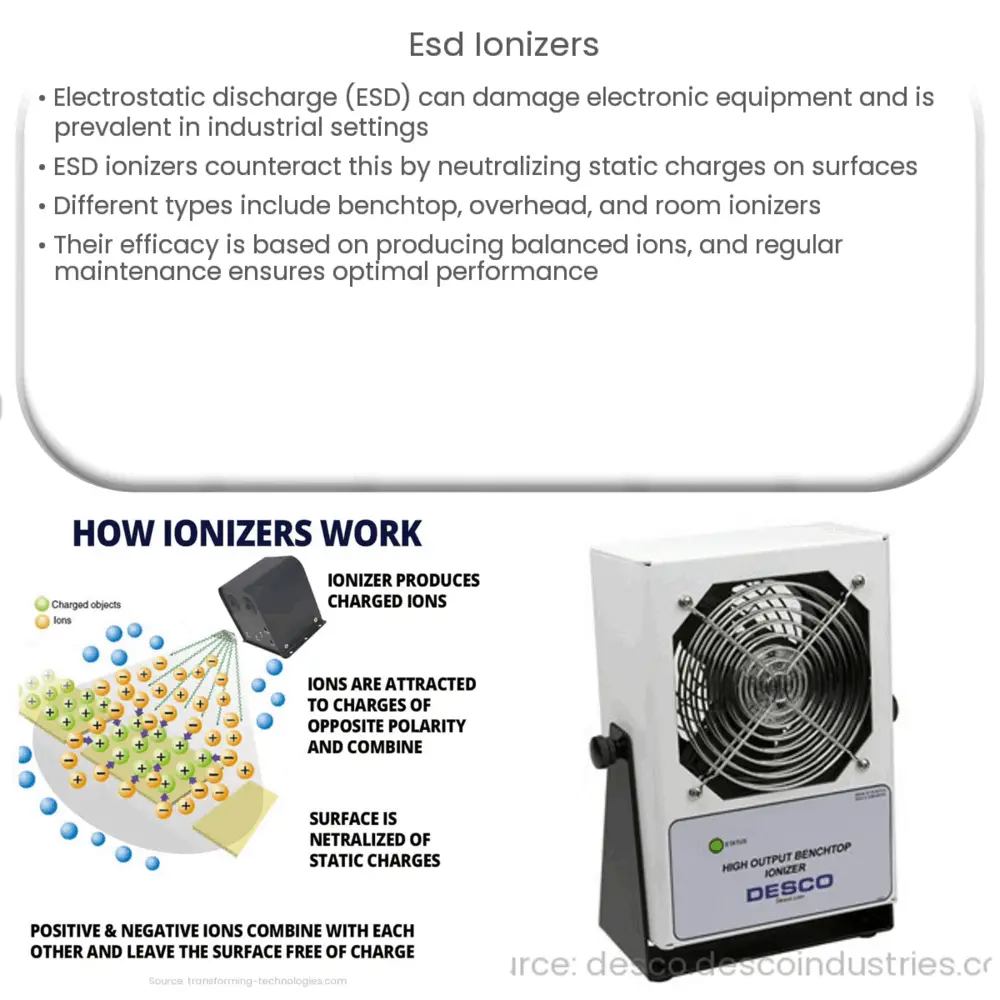

ESD ionizers, also known as static eliminators or anti-static devices, play a crucial role in managing and mitigating ESD in a variety of settings, from manufacturing plants to laboratories. These devices generate positive and negative ions using a method called corona discharge. This results in a stream of balanced ions which are then used to neutralize static charges on surfaces, thus mitigating the potential damage caused by ESD.

Types of ESD Ionizers

- Benchtop Ionizers: As the name suggests, these are designed for use on workbenches in industrial or technological environments. They’re typically used in areas where sensitive electronic components are handled, reducing the risk of ESD damage.

- Overhead Ionizers: These ionizers are installed overhead and are usually employed in larger spaces, where they can cover more area. They’re especially useful in environments where workspace is at a premium.

- Room Ionizers: These are designed to eliminate static across an entire room. Room ionizers are typically used in large-scale manufacturing and assembly areas.

How ESD Ionizers Work

The operating principle of ESD Ionizers is fairly straightforward. They generate ions using a high voltage power supply. This high voltage is applied to a sharp needle point (the emitter), causing the air molecules around the tip to ionize. The resulting ions are then propelled into the atmosphere by the repulsion of like charges and the attraction of opposite charges. Hence, they can neutralize any static charge present on a surface by supplying or removing the required quantity of charge.

Applications of ESD Ionizers

ESD Ionizers are utilized in a wide range of applications due to their versatile nature. These include electronic assembly, biomedical device manufacturing, cleanrooms, and semiconductor fabrication, among others. These settings often have static-sensitive components that can be severely damaged by ESD, hence the need for static control.

Choosing the Right ESD Ionizer

There are various factors to consider when choosing an ESD Ionizer for a specific application. Key among these are the ionizer’s type, size, ion balance, discharge time, and maintenance requirements. It’s also crucial to consider the size and nature of the area where the ionizer will be used. A comprehensive understanding of these factors can ensure the chosen ionizer provides effective static control in its designated setting.

- Ion Balance: The ion balance of an ionizer refers to its ability to produce an equal number of positive and negative ions. An ionizer with a good balance ensures that no static charge remains on a surface after neutralization.

- Discharge Time: Discharge time is the time it takes for an ionizer to neutralize a static charge. Faster discharge times are usually more desirable, especially in fast-paced industrial settings.

- Maintenance: Over time, the emitter points of an ionizer may become dirty or wear out, requiring cleaning or replacement. Therefore, an ionizer that’s easy to maintain and service will help to reduce downtime and operational costs.

The Importance of Regular Maintenance

Maintenance plays a critical role in the performance and longevity of ESD Ionizers. Regular cleaning and replacement of emitter points, as well as routine calibration, are necessary to ensure that the ionizer continues to function optimally. Failing to do so may lead to a buildup of static charge, rendering the ionizer ineffective and potentially causing damage to sensitive equipment.

Conclusion

In conclusion, ESD Ionizers play an essential role in various industries by managing and mitigating the potential damage caused by electrostatic discharge. Understanding the different types of ionizers, how they work, and their applications can help in making an informed choice. However, it’s also crucial to note the importance of maintenance for these devices. Regular upkeep and servicing not only enhance the effectiveness of ESD Ionizers but also extend their lifespan, ultimately contributing to a safer and more efficient working environment.