Explore the uses, types, and importance of ESD brushes in protecting sensitive electronics from damaging static discharge.

Understanding ESD Brushes

Electrostatic discharge (ESD) brushes are essential tools in various industries. These brushes are uniquely designed to reduce or eliminate the risks associated with electrostatic discharge in environments where electronic components are handled or manufactured.

ESD brushes are typically made of conductive or dissipative materials. This feature allows the safe redirection of any static electricity present to a grounded surface, thereby preventing damage to sensitive electronics.

Applications of ESD Brushes

ESD brushes have widespread applications across various industries. They are most commonly used in industries such as electronics manufacturing, computer technology, telecommunication, aerospace, and automotive industries where handling delicate electronic components is part of the daily operations.

- 1 Electronics Manufacturing: In the production and assembly of electronic devices, ESD brushes help prevent the build-up of static electricity that could potentially damage electronic components.

- 2 Computer Technology: When servicing or assembling computers, ESD brushes can protect sensitive parts like microprocessors and memory chips from static discharge.

- 3 Telecommunications: These brushes are used to clean and maintain equipment without the risk of electrostatic damage.

Types of ESD Brushes

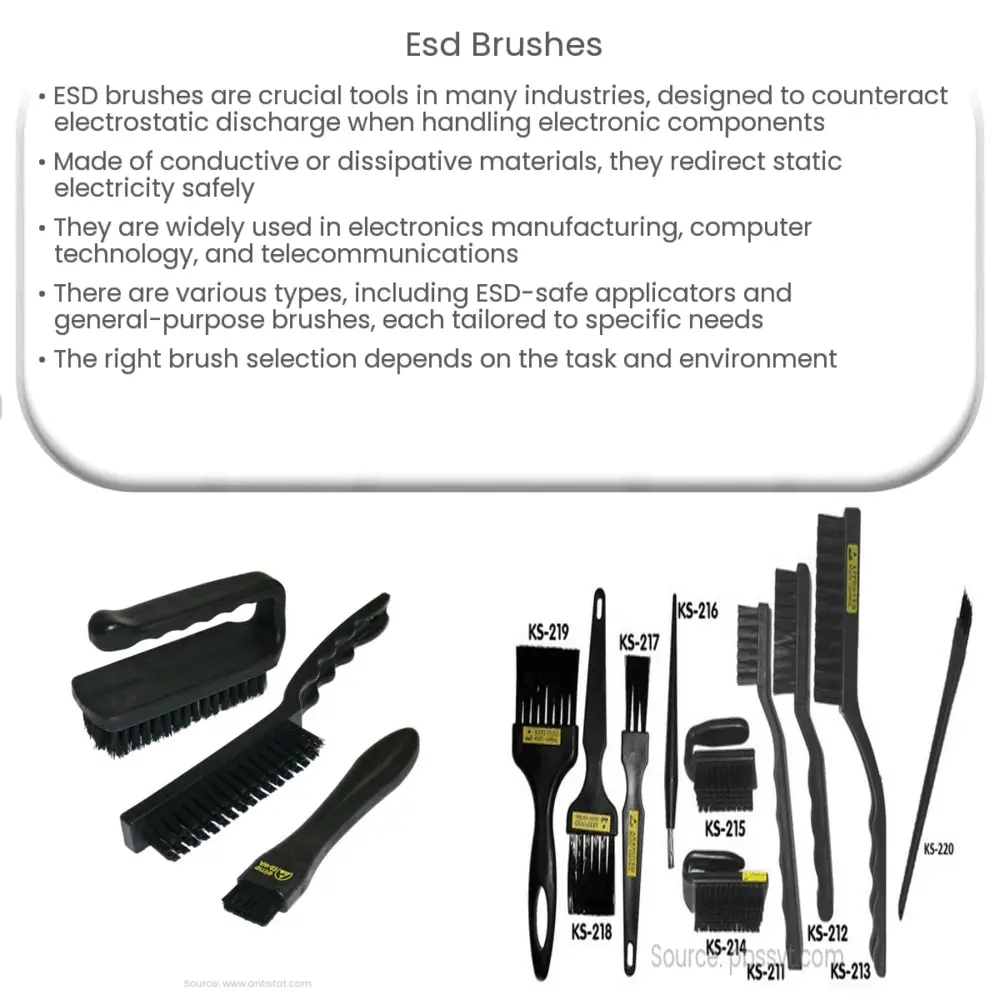

There are several types of ESD brushes, each designed to cater to specific needs and applications. These include ESD-safe brush applicators, ESD flux brushes, ESD general-purpose brushes, and ESD strip brushes.

- 1 ESD-safe Brush Applicators: These brushes are usually used to apply ESD coatings or other materials that require a brush for application.

- 2 ESD Flux Brushes: Flux brushes are used in soldering processes. They are specifically designed to apply flux evenly without generating electrostatic charges.

- 3 ESD General-Purpose Brushes: These are versatile brushes designed for a broad range of applications, from removing dust to scrubbing surfaces.

- 4 ESD Strip Brushes: These are used in sealing applications, such as on doors or other enclosures, to provide ESD protection while still allowing access.

Regardless of the type, ESD brushes are designed to ensure safety in the workplace, especially in industries dealing with sensitive electronics.

Selecting the Right ESD Brush

Choosing the appropriate ESD brush largely depends on the specific application and the environment. Here are some factors to consider:

- 1 Brush Size: ESD brushes come in various sizes. Depending on the task, one might need a large brush for cleaning large surfaces or a small one for intricate work.

- 2 Material: The material of the brush is crucial. For instance, brushes with softer bristles are suitable for delicate electronics, while stiffer ones are better for robust surfaces.

- 3 Type of Handle: The handle design and material can affect user comfort and brush control.

Importance of ESD Brushes

ESD brushes play a vital role in preventing unwanted static discharge that could damage electronic components. In industries where static electricity can have catastrophic effects, such as causing a spark in flammable atmospheres, ESD brushes are critical.

Their effectiveness, however, is not standalone. ESD brushes should be part of a broader Electrostatic Discharge Control Program, which might include ESD-safe workstations, ESD-safe storage, and training for employees on how to handle sensitive electronic components.

Conclusion

In conclusion, ESD brushes are indispensable tools in industries that handle sensitive electronic components. They not only help maintain a clean working environment but also provide an essential line of defense against the potentially harmful effects of electrostatic discharge. From manufacturing electronic devices to servicing computer systems, these brushes serve to protect valuable components from damage, maintaining their efficiency and longevity.

Choosing the right ESD brush necessitates a good understanding of the work environment and the specific tasks at hand. However, it’s important to note that ESD brushes form just one element of a comprehensive ESD control program, with the ultimate goal of ensuring a safe and productive work environment.