Explore the world of electrostatic separators, their types, workings, applications in various industries, and the future outlook.

Introduction to Electrostatic Separators

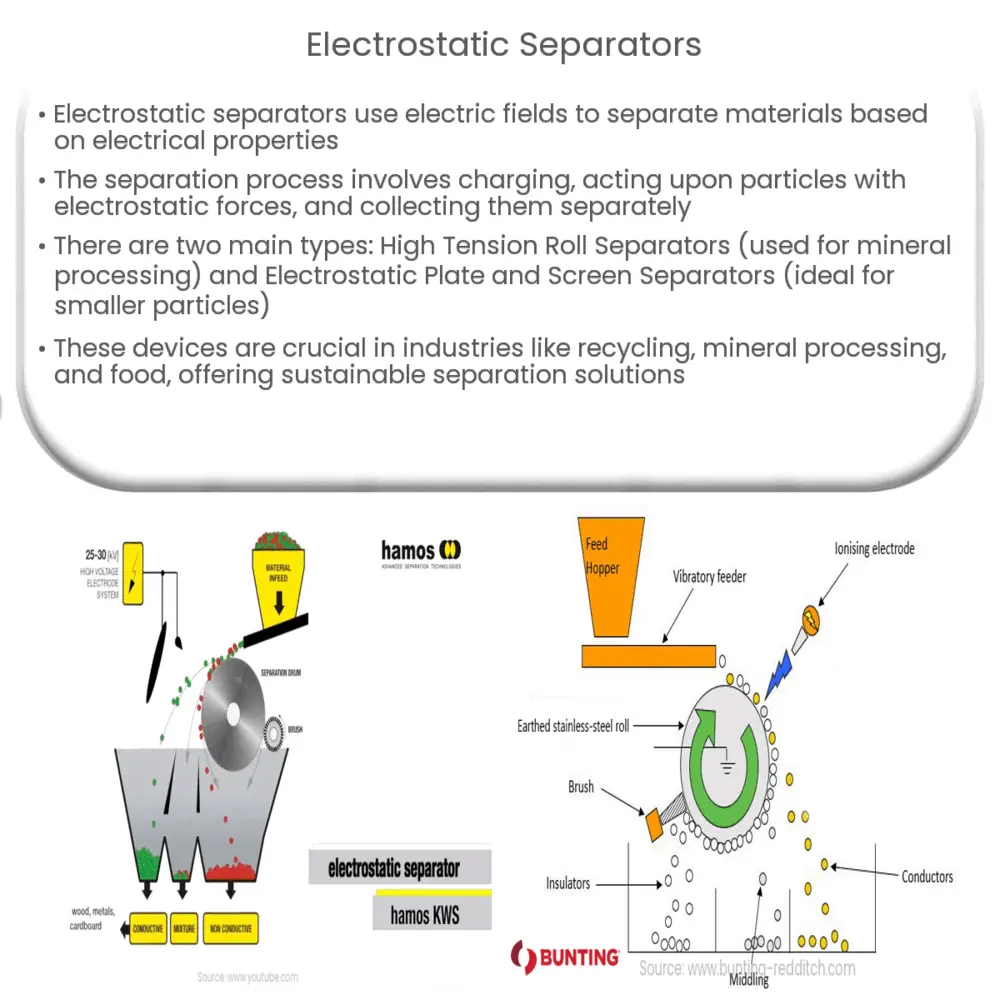

Electrostatic separators, critical devices in the recycling industry and mineral processing, harness the power of electric fields to separate materials according to their electrical properties. As material particles pass through these separators, they become electrically charged due to the influence of a high-voltage electric field. The degree of charging varies depending upon the properties of the material. Consequently, this variation in charging is exploited to achieve separation.

Working Principle of Electrostatic Separators

Electrostatic separation, as the name suggests, works on the principle of charge differences. When subjected to an electric field, particles with different properties acquire charges at varying levels. Following this, the charged particles experience an electrostatic force in the electric field. The disparity in the obtained forces results in a different trajectory for each particle, thus effecting separation.

- Charging: In the initial stage, particles are charged by ion bombardment or by contact with a charged surface.

- Separation: The charged particles are then introduced to an electric field where they are acted upon by electrostatic forces.

- Collection: Lastly, particles following different trajectories based on their respective charges are collected separately.

Types of Electrostatic Separators

Electrostatic separators come in various configurations to suit different applications. They can be broadly categorized into two types:

- High Tension Roll Separators (HTRS): HTRS are commonly used for the separation of conductive minerals and non-conductive minerals. These separators apply a high voltage direct current to a conducting roller, causing ion bombardment at the feed material.

- Electrostatic Plate and Screen Separators: These separators use metal plates charged with an electric current, creating an electric field that can be used to separate material. They are generally used for separating smaller particles.

Applications of Electrostatic Separators

Due to their ability to efficiently separate materials based on their electrical properties, electrostatic separators find applications in a wide range of industries. These include but are not limited to:

- Recycling industry: separating different components of waste

- Mineral processing: separation of minerals based on their conductivity

- Food industry: removal of metal impurities

This is just a broad overview of what electrostatic separators are, their working principle, types, and applications. However, to truly understand their significance and impact, we must delve deeper into each aspect. This exploration forms the second part of our discussion.

Detailed Analysis of Electrostatic Separator Types

As mentioned earlier, there are primarily two types of electrostatic separators – High Tension Roll Separators (HTRS) and Electrostatic Plate and Screen Separators. Let’s delve deeper into their specific workings and benefits.

High Tension Roll Separators

High Tension Roll Separators (HTRS) feature a roll made from a conductive material, which is energized by a high voltage direct current. As the feed material is dispersed onto the roll, particles get ionized due to ion bombardment. The degree of ionization varies, and this difference in charging is utilized to separate particles as they fall off the roll.

One significant advantage of HTRS is their high efficiency in separating conductive and non-conductive minerals, making them ideal for mineral processing applications.

Electrostatic Plate and Screen Separators

Electrostatic Plate and Screen Separators work by passing the material over a charged screen or plate. The electrostatic field around the plate charges the particles, and the resultant force separates the particles based on their conductivity and size.

These separators are highly effective for separating smaller particles, and they are extensively used in applications where precise separation is required, like in the food industry for the removal of metallic impurities.

Challenges and Solutions in Electrostatic Separation

While electrostatic separation is highly effective, it does face certain challenges. Moisture content, particle size, and material characteristics can significantly affect the process’s efficiency. However, technological advancements like online particle size analyzers and moisture control systems have been developed to tackle these issues and improve the overall separation process.

Conclusion

In conclusion, electrostatic separators have a crucial role in many industries, from recycling to mineral processing and the food industry. Their capacity to effectively and efficiently separate materials based on electrical properties is unparalleled. Although there are challenges associated with electrostatic separation, continuous technological advancements are enhancing the process’s effectiveness and efficiency. With sustainable practices becoming increasingly important, the role of electrostatic separators in waste management and recycling is expected to grow significantly. As we continue to innovate and improve these technologies, their potential applications may extend even further, reinforcing their importance in our increasingly resource-conscious world.