Electrostatic induction motors use electrostatic forces for motion, offering high efficiency, silent operation, and low maintenance in various applications.

Electrostatic Induction Motor: A Primer

Introduction

Electrostatic induction motors have become an increasingly popular topic of discussion in recent years, with the potential to revolutionize the electric motor industry. These motors use electrostatic forces rather than electromagnetic forces to generate motion, providing a number of advantages over traditional electric motors. In this article, we will explore the principles behind electrostatic induction motors, their advantages, and their potential applications.

Principles of Electrostatic Induction Motors

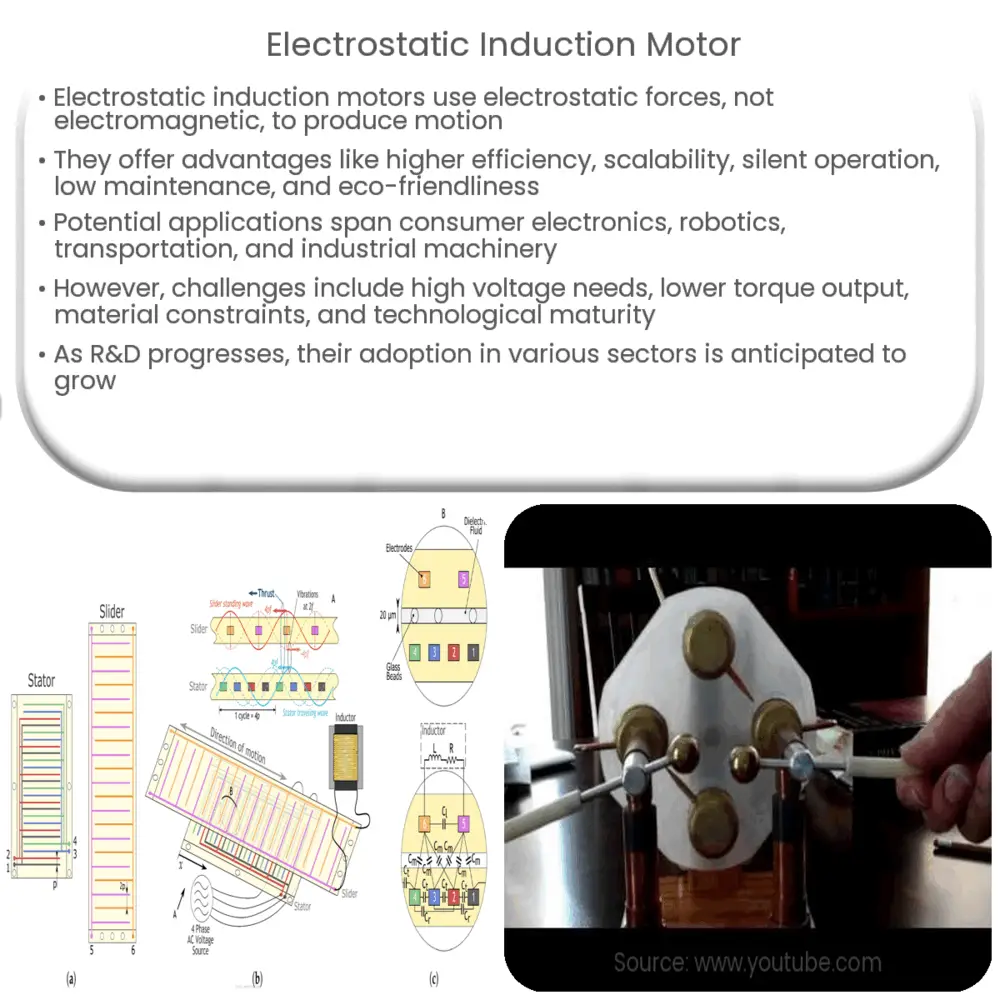

Electrostatic induction motors operate based on the phenomenon of electrostatic induction, wherein a charged object can induce a charge in a nearby object without direct contact. This principle is fundamentally different from that of conventional electric motors, which rely on electromagnetic induction to generate motion.

At the core of an electrostatic induction motor is a stator, which consists of a series of electrically conductive plates separated by insulating material. These plates are charged by a high-voltage power supply, creating an electric field. The rotor, which is also made of conductive material, is placed within the stator and exposed to the electric field. The induced charges on the rotor cause it to experience electrostatic forces, which in turn create motion.

By modulating the charges on the stator plates in a controlled manner, it is possible to achieve continuous rotation of the rotor. This can be achieved through various mechanisms, such as switching the voltage polarity on the stator plates or using an array of capacitors to create a moving electric field.

Advantages of Electrostatic Induction Motors

Electrostatic induction motors offer several key advantages over conventional electric motors. Some of these benefits include:

- Efficiency: Due to the absence of magnetic losses and reduced friction, electrostatic induction motors have the potential to be significantly more energy efficient than traditional motors.

- Scalability: The simple design and small size of electrostatic induction motors make them easily scalable for a wide range of applications, from micro-scale devices to large industrial machines.

- Silent Operation: Unlike electromagnetic motors, which generate noise from vibrations and magnetic forces, electrostatic induction motors operate silently.

- Low Maintenance: The lack of moving parts in the motor design, combined with the absence of friction and wear, results in lower maintenance requirements.

- Environmentally Friendly: The absence of electromagnetic interference and the reduced energy consumption make electrostatic induction motors an environmentally friendly alternative to traditional motors.

Potential Applications

Electrostatic induction motors have a wide range of potential applications across various industries. Some examples include:

- Consumer Electronics: These motors could be used in devices such as smartphones, tablets, and wearable technology, where silent operation and low power consumption are essential.

- Robotics: The high efficiency, low maintenance, and scalability of electrostatic induction motors make them an attractive option for robotic systems and automation.

- Transportation: Electric vehicles could benefit from the improved efficiency and reduced weight of electrostatic induction motors.

- Industrial Machinery: The silent operation and low maintenance requirements of these motors make them ideal for use in a variety of industrial settings.

Challenges and Limitations

Despite the numerous advantages, electrostatic induction motors also face several challenges and limitations that need to be addressed before they can be widely adopted:

- High Voltage Requirement: The operation of electrostatic induction motors requires high voltage levels, which can pose safety concerns and demand specialized components to manage these voltages effectively.

- Lower Torque Output: Compared to electromagnetic motors, electrostatic induction motors typically have lower torque output, which could limit their usefulness in certain applications requiring high torque.

- Material Challenges: The insulating materials used in electrostatic induction motors must withstand high voltages and maintain their insulating properties. This necessitates the use of advanced materials and careful engineering.

- Technological Maturity: Electrostatic induction motors are still a relatively new technology compared to conventional electric motors, and further research and development is needed to optimize their performance and address the aforementioned challenges.

Future Prospects

As research and development in the field of electrostatic induction motors continues, it is expected that many of the current challenges and limitations will be overcome. Innovative solutions, such as the development of advanced insulating materials and improved high-voltage management systems, can help address some of the key issues.

The potential applications and advantages of electrostatic induction motors make them an exciting area of research, with the potential to disrupt the electric motor market. As the technology matures and becomes more accessible, we can expect to see increased adoption of electrostatic induction motors in various industries, from consumer electronics to transportation and beyond.

Conclusion

Electrostatic induction motors represent a promising and innovative technology that offers numerous advantages over traditional electric motors, including higher efficiency, silent operation, and reduced maintenance requirements. Although there are still challenges to be addressed, the technology’s potential to revolutionize the electric motor industry cannot be overlooked. As research and development continue, we can expect to see electrostatic induction motors become increasingly prevalent in a wide range of applications, ultimately transforming the way we generate motion in our daily lives.