Differential pressure level sensors accurately measure fluid levels in various industries, offering high reliability, compatibility, and cost-effectiveness.

Differential Pressure Level Sensor: An Overview

Introduction

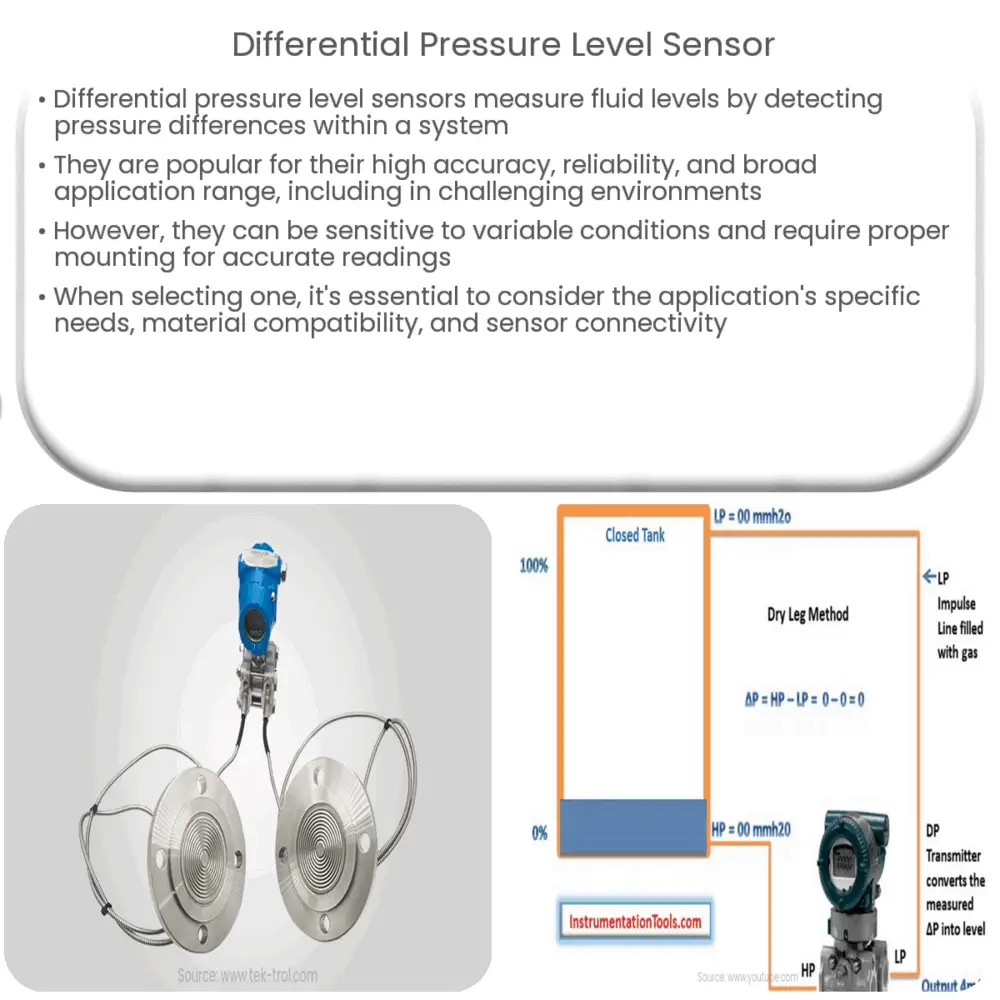

Differential pressure level sensors are widely used in various industries for accurate and reliable level measurement. They are particularly popular in applications where conventional level sensors may face limitations due to the nature of the process or environment. This article aims to provide an overview of differential pressure level sensors, their working principle, and the advantages they offer in comparison to other level sensing technologies.

Working Principle

The primary principle behind a differential pressure level sensor is the measurement of the pressure difference between two points within a fluid-filled system. One point is typically located at the bottom of the tank or vessel, while the other is situated at the reference point, which can be the top of the tank or at the surface of the liquid. The pressure difference between these two points is directly proportional to the height or level of the liquid within the container.

In practical applications, differential pressure level sensors consist of two main components: a pressure transmitter and a diaphragm seal. The pressure transmitter measures the pressure exerted by the fluid on the diaphragm seal, which is then converted into an electrical signal. This signal is then sent to a control system or display for analysis and interpretation.

Advantages of Differential Pressure Level Sensors

Differential pressure level sensors offer several advantages over other level sensing technologies, making them the preferred choice in various industrial applications:

- Wide Range of Applications: Differential pressure level sensors are suitable for measuring the level of a wide variety of liquids, including corrosive and viscous fluids, as well as fluids with high temperatures and pressures.

- High Accuracy: These sensors are known for their high accuracy, typically within ±0.1% to ±0.25% of the full scale, making them ideal for precise level measurement.

- Reliability: Differential pressure level sensors are robust and reliable, with a long service life and minimal maintenance requirements.

- Compatibility: These sensors can be easily integrated into existing process control systems, providing seamless operation and data collection.

- Cost-Effectiveness: In comparison to other level sensing technologies, differential pressure level sensors are generally more affordable, especially for large-scale or complex installations.

Limitations of Differential Pressure Level Sensors

Despite their numerous advantages, differential pressure level sensors do have some limitations:

- Sensitivity to Process Conditions: Changes in fluid density, temperature, and pressure can affect the accuracy of differential pressure level sensors, making them less suitable for applications with highly variable conditions.

- Mounting Constraints: Proper installation is critical for accurate level measurement. The sensor must be correctly mounted, ensuring the diaphragm seal is aligned with the fluid level to minimize measurement errors.

- Foaming or Vapors: The presence of foam or vapor layers within the fluid can cause inaccuracies in the level measurement, as the sensor may not correctly account for these layers when determining the pressure difference.

Selecting the Right Differential Pressure Level Sensor

When choosing a differential pressure level sensor, several factors should be considered to ensure optimal performance and accuracy:

- Application Requirements: Evaluate the specific needs of your application, including the type of fluid, temperature, pressure, and the required level of accuracy.

- Material Compatibility: The sensor materials should be compatible with the fluid being measured to avoid corrosion or other adverse reactions.

- Installation and Maintenance: Consider the ease of installation and maintenance when selecting a sensor, as this will impact the overall cost and reliability of the system.

- Output and Connectivity: Ensure the sensor is compatible with your existing control systems and provides the necessary output and communication options for seamless integration.

Conclusion

Differential pressure level sensors are versatile, accurate, and reliable instruments for measuring fluid levels in various industrial applications. By understanding their working principle, advantages, limitations, and selection criteria, users can choose the right sensor to meet their specific needs and optimize their level measurement processes. While some limitations exist, differential pressure level sensors remain a popular choice for many industries due to their cost-effectiveness, compatibility, and high accuracy.