Dielectric impedance analyzers are instruments used to evaluate materials’ electrical properties, aiding in optimization and research across various industries.

Dielectric Impedance Analyzer: An Essential Tool for Material Characterization

Introduction

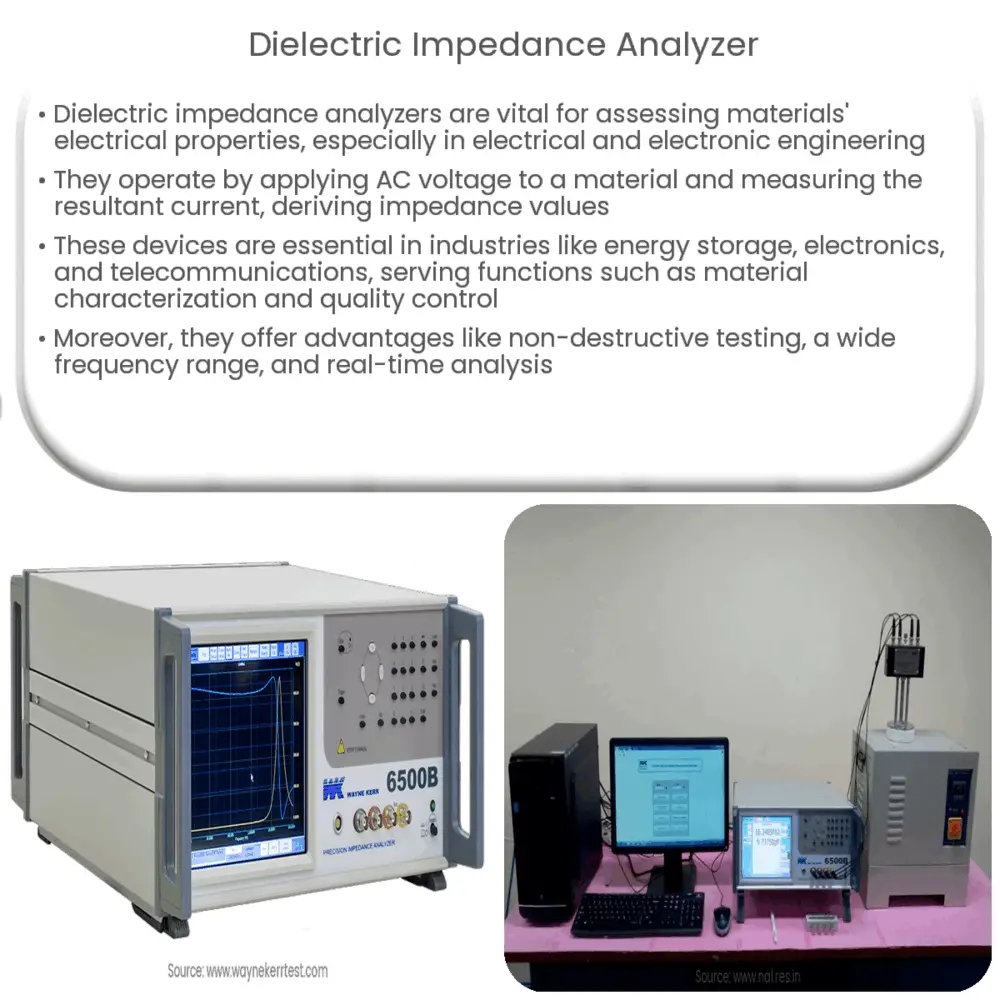

Dielectric impedance analyzers are advanced instruments that play a critical role in the evaluation and characterization of materials, particularly in the field of electrical and electronic engineering. This versatile device allows researchers and engineers to study the electrical properties of various materials, such as their capacitance, conductance, and impedance, over a wide range of frequencies. This information is invaluable for optimizing material performance and designing innovative products for various industries, including energy storage, electronics, and telecommunications.

Principle of Operation

Dielectric impedance analyzers function by applying a small AC voltage to the material under test and measuring the resulting current. The device then calculates the impedance (Z), which is the ratio of the applied voltage to the measured current, and its phase angle (θ). These values are used to derive the real (resistive) and imaginary (reactive) components of the material’s impedance, which provide insights into its electrical properties, such as dielectric constant, conductivity, and dissipation factor.

Key Components of a Dielectric Impedance Analyzer

A typical dielectric impedance analyzer comprises several key components, including a frequency generator, a voltage/current measurement unit, a data acquisition system, and a computer interface for data analysis and display. The frequency generator is responsible for generating the AC voltage at various frequencies, while the voltage/current measurement unit measures the voltage across and current through the material under test. The data acquisition system captures and processes the raw data, and the computer interface allows the user to analyze, visualize, and interpret the results.

Applications of Dielectric Impedance Analyzers

Dielectric impedance analyzers find applications across a wide range of industries and research domains. Some of the most common applications include:

- Material Characterization: Dielectric impedance analyzers are widely used to study the electrical properties of various materials, including polymers, ceramics, composites, and liquid electrolytes. This information is crucial for optimizing material performance and selecting the right materials for specific applications.

- Quality Control: Manufacturers use dielectric impedance analyzers to ensure the consistency and quality of their products by monitoring the electrical properties of materials during production.

- Research and Development: Researchers use dielectric impedance analyzers to study the effects of various factors, such as temperature, humidity, and aging, on the electrical properties of materials, which helps them develop new materials with improved performance.

- Energy Storage: Dielectric impedance analyzers play a crucial role in the development and optimization of energy storage devices, such as capacitors and batteries, by characterizing the dielectric properties and performance of the materials used in these devices.

Advantages of Dielectric Impedance Analyzers

Dielectric impedance analyzers offer several advantages over other material characterization techniques, which include:

- Non-destructive Testing: Unlike some other material testing methods, dielectric impedance analysis is non-destructive, which means that the material under test remains unaltered and can be used for further testing or applications.

- Wide Frequency Range: Dielectric impedance analyzers can operate over a broad range of frequencies, enabling researchers to study the material’s electrical properties across various frequency domains, providing a comprehensive understanding of the material’s behavior.

- High Sensitivity: Dielectric impedance analyzers are highly sensitive instruments, capable of detecting minute changes in the material’s electrical properties, which makes them ideal for detecting defects, impurities, and other anomalies in the material.

- Real-time Analysis: Dielectric impedance analyzers allow for real-time data acquisition and analysis, which helps researchers and engineers to quickly identify trends and make informed decisions.

Selecting the Right Dielectric Impedance Analyzer

When choosing a dielectric impedance analyzer, several factors should be taken into consideration, including:

- Frequency Range: Ensure that the analyzer’s frequency range is suitable for the intended application, as the material’s electrical properties can vary significantly across different frequency domains.

- Accuracy and Resolution: The accuracy and resolution of the analyzer are crucial for obtaining reliable and precise measurements. High-quality instruments provide better accuracy and resolution, which translates to more accurate and detailed results.

- Measurement Speed: The speed at which the analyzer can perform measurements is essential, especially in applications where rapid data acquisition and analysis are required, such as quality control and high-throughput testing.

- Software and Connectivity: The analyzer’s software and connectivity options should be user-friendly and compatible with your existing computer systems, allowing for seamless integration and data analysis.

Conclusion

Dielectric impedance analyzers are indispensable tools for characterizing the electrical properties of materials, enabling researchers and engineers to optimize material performance and develop innovative products across various industries. By understanding the working principles, applications, and advantages of dielectric impedance analyzers, and considering key factors when selecting the right instrument, users can effectively leverage these devices to advance material research, ensure product quality, and drive technological innovation.