Despite the considerable promise shown by conductive polymer supercapacitors, some challenges need to be addressed. One of the major issues is the relatively poor mechanical stability of conductive polymers.

Understanding Conductive Polymers

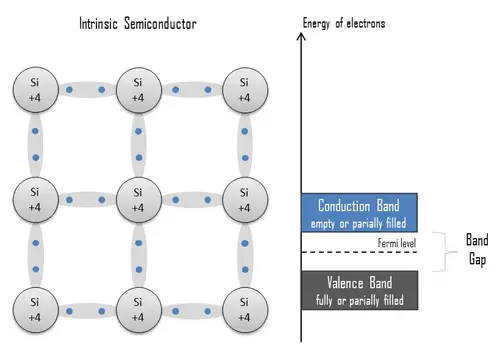

Conductive polymers are a unique class of polymers that significantly deviate from the general perception of insulating plastic materials. They are composed of long, chain-like molecules with a significant degree of π-conjugation, enabling them to conduct electricity. This conductivity arises from the delocalization of π-electrons along the polymer backbone, which allows the movement of charge carriers. The conductive polymer family includes polyaniline, polyacetylene, polypyrrole, and polythiophene, among others.

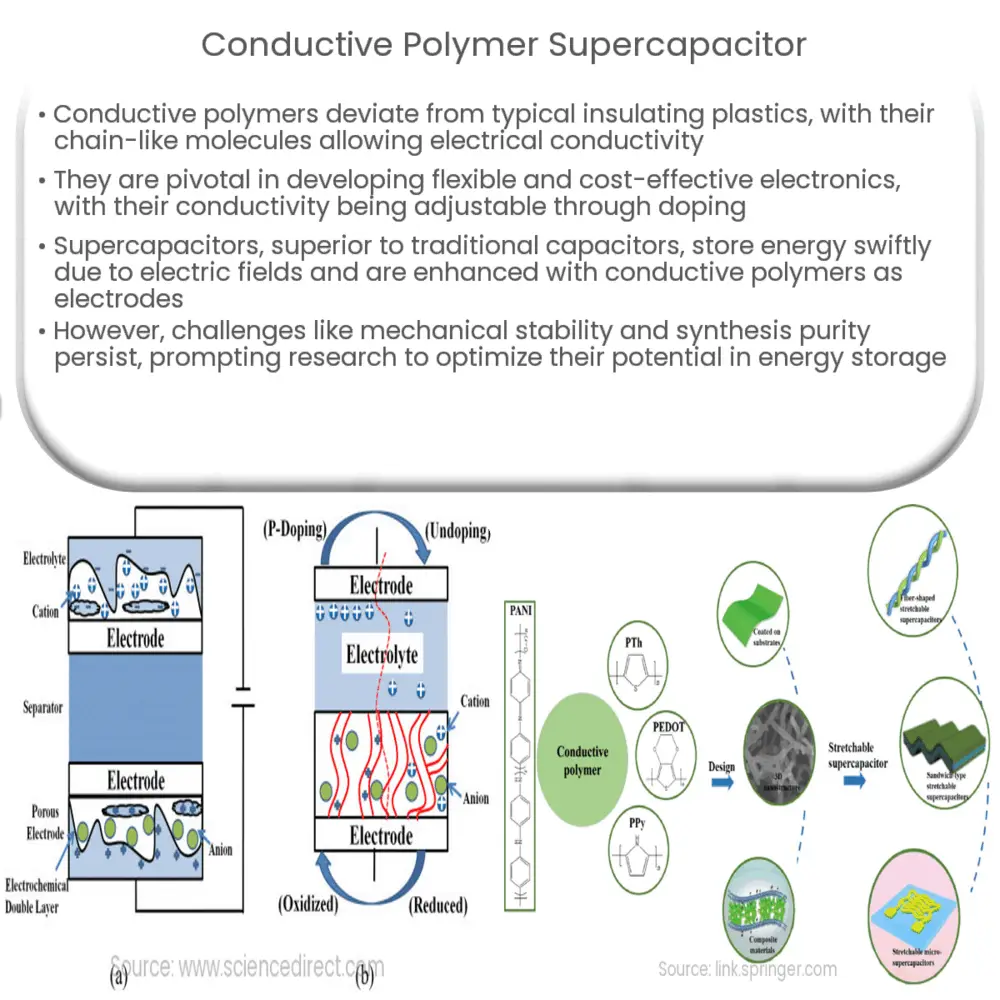

Notably, these polymers can be processed like traditional polymers, offering the potential to create flexible, lightweight, and cost-effective electronic devices. Their conductivity can also be controlled by manipulating their doping level – a process of adding impurities to increase or decrease conductivity. This unique combination of properties makes conductive polymers ideal candidates for a wide range of applications, including supercapacitors.

Supercapacitors and Their Role in Energy Storage

Supercapacitors, also known as ultracapacitors or electrochemical capacitors, are energy storage devices that offer higher power density and longer life cycles compared to traditional capacitors. They operate through the rapid charge and discharge of ions at the interface of conductive electrodes and an electrolyte.

Unlike batteries, which store energy via slow chemical reactions, supercapacitors store energy in an electric field, enabling them to charge and discharge quickly. They are also capable of withstanding a larger number of charge-discharge cycles, making them more durable and reliable in applications that require frequent cycling.

There are three types of supercapacitors: electrochemical double-layer capacitors (EDLCs), pseudocapacitors, and hybrid capacitors. EDLCs store charge in an electric double layer formed at the electrode-electrolyte interface. Pseudocapacitors, on the other hand, store energy through faradaic redox reactions that happen on the surface of the electrodes. Hybrid capacitors combine features from both EDLCs and pseudocapacitors, delivering both high energy and power densities.

In recent years, the field of supercapacitors has seen substantial advancements, particularly in the development of novel electrode materials. Conductive polymers have emerged as a promising material for supercapacitor electrodes due to their high conductivity, electrochemical stability, and easy processability.

Conductive Polymer Supercapacitors: Bridging the Gap

Conductive polymer supercapacitors offer an exciting pathway to bridge the gap between conventional capacitors and batteries. They combine the high power density of capacitors with the energy density closer to batteries, while also offering excellent cycle life and fast charge-discharge capabilities.

The working principle of conductive polymer supercapacitors is similar to other supercapacitors, but with a twist. In these devices, conductive polymers serve as the electrode material. When voltage is applied, ions from the electrolyte adsorb onto the surface of the conductive polymer, resulting in charge storage.

The key to the high performance of these supercapacitors lies in the unique properties of conductive polymers. They offer high conductivity, good electrochemical stability, and their structure can be easily tailored to optimize performance. Additionally, their pseudocapacitive behavior, resulting from fast and reversible faradaic reactions, leads to a higher energy density compared to EDLCs.

Challenges and Future Perspectives

Despite the considerable promise shown by conductive polymer supercapacitors, some challenges need to be addressed. One of the major issues is the relatively poor mechanical stability of conductive polymers. During repeated charge-discharge cycles, they can swell and contract, leading to a gradual degradation in performance.

Another challenge lies in the polymer’s synthesis. Achieving high purity and consistent quality can be difficult, which can impact the overall performance of the supercapacitor. Further, conductive polymers often require complex doping processes to achieve desirable conductivity levels, adding to the complexity and cost of manufacturing.

Addressing these challenges is crucial for the future of conductive polymer supercapacitors. Researchers are actively exploring strategies such as the use of composite materials, co-polymers, and advanced synthesis techniques to enhance the durability, performance, and manufacturability of these materials. With ongoing research and development, conductive polymer supercapacitors have the potential to revolutionize energy storage and power delivery in a wide range of applications, from portable electronics to electric vehicles and renewable energy systems.