A conductive plastic potentiometer is a durable variable resistor that offers better linearity, lower noise, and improved temperature stability for precise control in various applications.

Conductive Plastic Potentiometer: An Overview

A potentiometer is a variable resistor that can be used to control electrical devices such as volume controls, light dimmers, and motor speed controllers. Traditionally, potentiometers were made from carbon-based materials, which had limitations in terms of durability and performance. In recent years, there has been a shift towards using conductive plastic potentiometers for their improved performance and reliability. In this article, we will explore the advantages of conductive plastic potentiometers, their applications, and the future of this technology.

What is a Conductive Plastic Potentiometer?

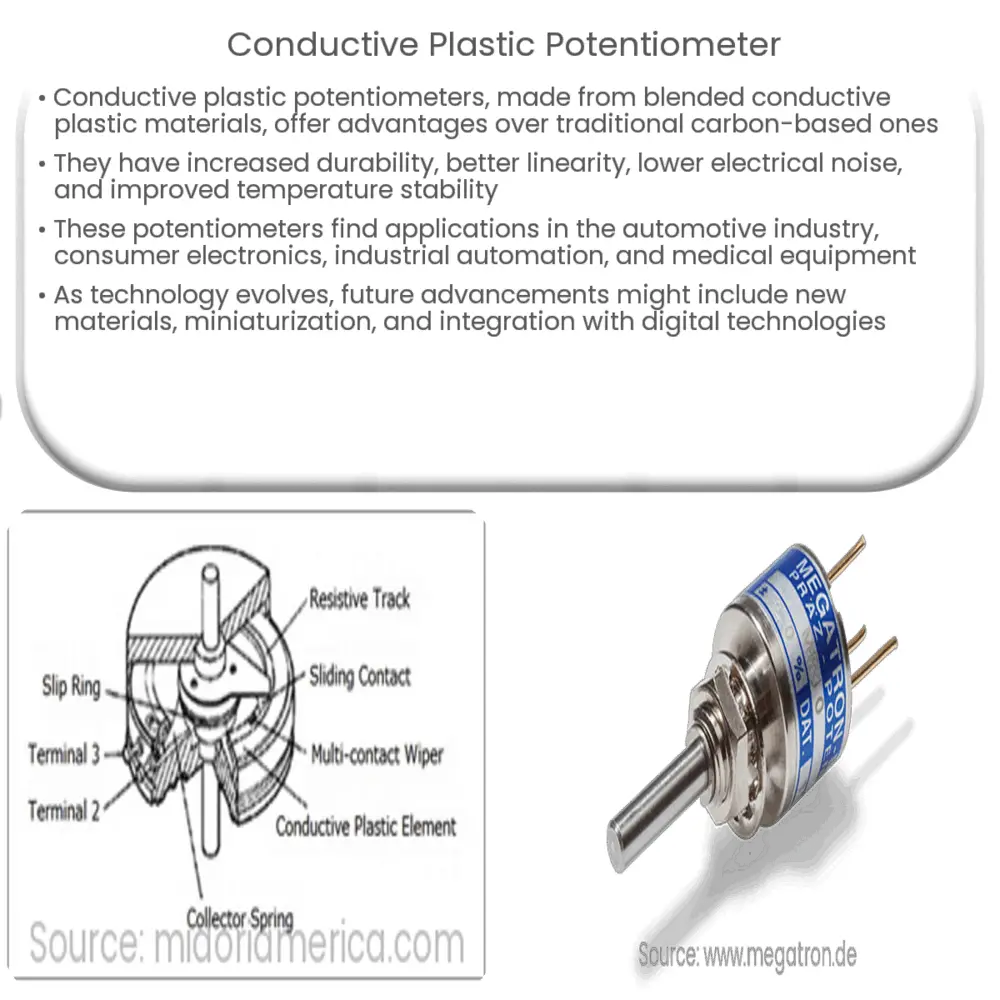

A conductive plastic potentiometer is a type of variable resistor that uses a conductive plastic material as the resistive element. The resistive track is formed from a blend of conductive plastic materials, such as polyethylene, polypropylene, or polystyrene, mixed with conductive particles like carbon or metal. The wiper, which is the part that slides along the resistive track to vary the resistance, is usually made from a precious metal to ensure low and consistent contact resistance.

Advantages of Conductive Plastic Potentiometers

There are several advantages to using conductive plastic potentiometers over traditional carbon-based potentiometers, including:

- Increased Durability: Conductive plastic potentiometers have a longer lifespan due to the reduced wear on the resistive track. This is because the conductive plastic material is more resistant to wear and tear than traditional carbon materials, resulting in a more durable potentiometer.

- Better Linearity: The conductive plastic materials used in these potentiometers provide a more linear response, which means that the output voltage varies more predictably with the position of the wiper. This leads to a more accurate and stable control of the electrical devices they are used in.

- Lower Noise: Conductive plastic potentiometers generate less electrical noise than their carbon counterparts, resulting in a cleaner and more stable signal. This is particularly important in applications like audio equipment, where noise can affect the quality of the output.

- Improved Temperature Stability: Conductive plastic potentiometers exhibit a lower temperature coefficient, meaning that their resistance remains more stable over a wide range of temperatures. This makes them suitable for use in environments with extreme temperature variations.

Applications of Conductive Plastic Potentiometers

Conductive plastic potentiometers are used in a variety of applications, including:

- Automotive industry: They are used in throttle position sensors, steering angle sensors, and suspension height sensors.

- Consumer electronics: In devices such as televisions, audio equipment, and home automation systems, conductive plastic potentiometers are used for volume control, light dimming, and motor speed control.

- Industrial automation: These potentiometers are used to control motor speed, position feedback, and process control in manufacturing equipment and robotics.

- Medical equipment: They play a vital role in controlling the movement and positioning of medical devices, such as surgical instruments and imaging equipment.

Manufacturing Process of Conductive Plastic Potentiometers

The manufacturing process for conductive plastic potentiometers involves several steps:

- Material Preparation: The conductive plastic material, which consists of a polymer mixed with conductive particles, is prepared by blending the components together. The mixture is then heated to create a homogeneous and consistent material.

- Resistive Track Formation: The conductive plastic material is then formed into a thin film, which will serve as the resistive track of the potentiometer. This can be done through various methods, such as extrusion, calendaring, or injection molding.

- Assembly: The resistive track is then attached to a substrate, usually made from a non-conductive material like fiberglass or ceramic. The wiper, made of a precious metal, is then assembled with the resistive track, along with the terminals and housing components.

- Testing and Quality Control: Each potentiometer undergoes rigorous testing to ensure it meets the required performance specifications, such as resistance range, linearity, and electrical noise. Quality control measures are in place to ensure the consistency and reliability of the final product.

Future of Conductive Plastic Potentiometers

As technology advances and new applications emerge, the demand for high-performance and reliable potentiometers is expected to grow. The future of conductive plastic potentiometers may include:

- New Materials: Researchers are exploring the use of advanced materials, such as graphene and carbon nanotubes, to further improve the performance and durability of conductive plastic potentiometers.

- Miniaturization: As electronic devices become smaller and more compact, there is a need for potentiometers that can fit into these smaller form factors. This could lead to the development of miniaturized conductive plastic potentiometers for use in devices like wearables, IoT sensors, and portable electronics.

- Integration with Digital Technologies: The integration of conductive plastic potentiometers with digital technologies, such as microcontrollers and digital signal processors, could enable new applications and capabilities, such as smart sensors and adaptive control systems.

Conclusion

Conductive plastic potentiometers have become the preferred choice for many applications due to their improved performance, reliability, and durability compared to traditional carbon-based potentiometers. As new materials and manufacturing processes are developed, the potential applications and capabilities of conductive plastic potentiometers will continue to expand, making them an essential component in a wide range of industries and technologies.