Explore the workings, advantages, and applications of Capacitor-Run Induction Motors, along with their limitations and construction details.

Introduction to Capacitor-Run Induction Motors

The world of electric motors is broad and diverse, with various types serving a myriad of applications. One such variant is the Capacitor-Run Induction Motor. These motors are commonly used in applications requiring high efficiency and torque over a wide speed range, such as fans, pumps, and compressors.

How Capacitor-Run Induction Motors Work

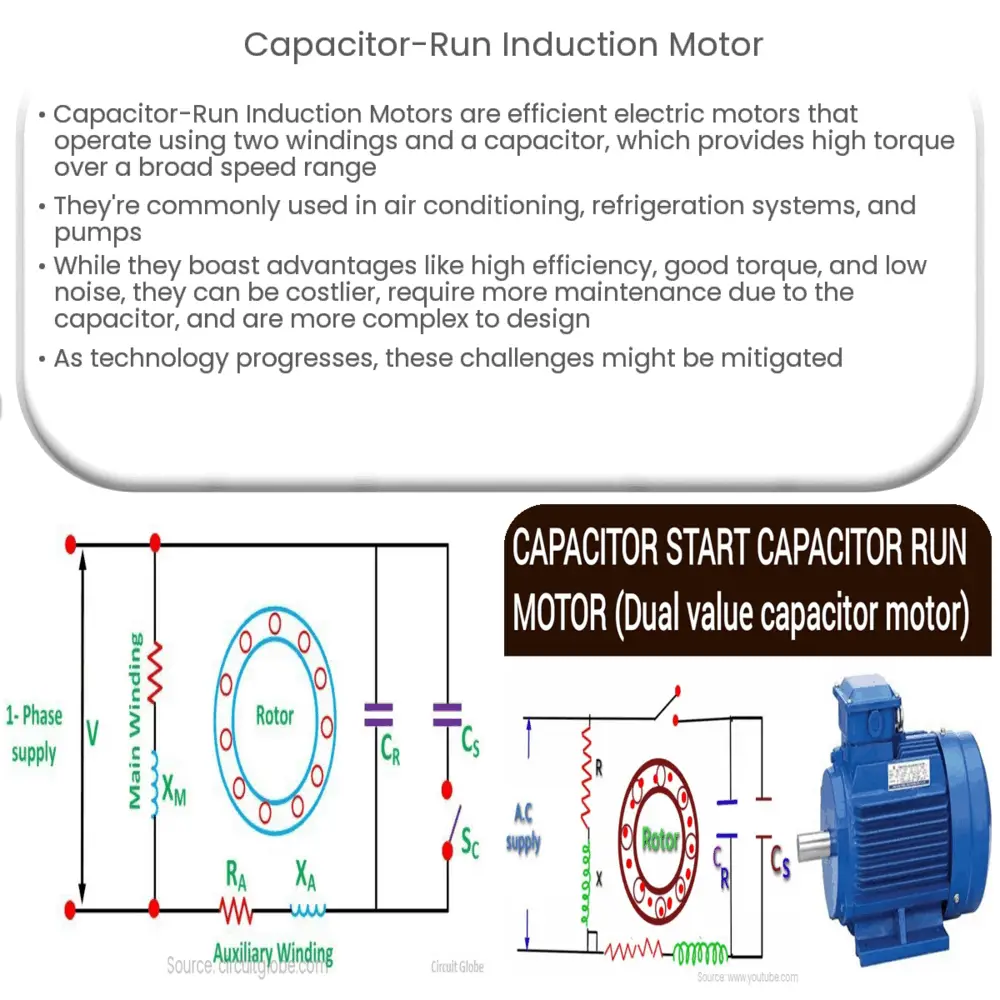

The Capacitor-Run Induction Motor, sometimes also referred to as a ‘two-value’ or ‘permanent-split capacitor’ motor, operates based on the principles of electromagnetic induction. It has two windings – the main winding and the auxiliary winding. The main winding is connected directly to the supply voltage, while the auxiliary winding is connected via a capacitor.

The role of the capacitor is to create a phase shift between the currents in the two windings. This phase shift results in a rotating magnetic field which induces a current in the rotor, thus causing it to rotate. Since the capacitor is in the circuit during the entire operation, the motor can maintain a high torque over a wide speed range.

Advantages of Capacitor-Run Induction Motors

- High Efficiency: These motors are known for their high efficiency, which makes them suitable for continuous operation.

- Torque: Capacitor-run motors provide good torque over a wide speed range, making them ideal for various applications.

- Noise: They operate with less noise compared to other motor types.

Applications of Capacitor-Run Induction Motors

- Capacitor-Run Induction Motors are used in air conditioning units, where they provide the necessary torque for operating the fan.

- In refrigeration systems, they drive the compressor.

- These motors are also commonly used in pump systems due to their ability to deliver consistent torque over a wide speed range.

Though these motors offer numerous advantages, they do have a few drawbacks. For example, they can be more costly and complex than other types of motors. Additionally, the capacitor may require replacement over time, adding to maintenance requirements.

Construction of Capacitor-Run Induction Motors

Capacitor-Run Induction Motors typically have a stator, a rotor, and a capacitor. The stator is the stationary part of the motor, which consists of the main and auxiliary windings. The rotor, the moving part of the motor, is usually of the squirrel-cage type.

The two windings are placed in the stator at a 90o angle to each other. The capacitor is connected in series with the auxiliary winding. This capacitor is designed to withstand continuous operation over the motor’s entire speed range.

Limitations of Capacitor-Run Induction Motors

- Cost: These motors are usually more expensive due to the addition of a capacitor and the requirement of two windings.

- Maintenance: The capacitors can degrade over time and may need replacement, increasing the maintenance cost.

- Complexity: The use of two windings and a capacitor adds to the complexity of these motors, making them more difficult to design and manufacture.

Conclusion

In conclusion, Capacitor-Run Induction Motors are an important category of electric motors that offer high efficiency and good torque characteristics over a wide speed range. They find extensive use in various applications like air conditioning units, refrigeration systems, and pump systems.

Despite their limitations, including higher costs, increased maintenance, and complexity, their advantages make them a preferred choice in many situations. As technology advances, there may be ways to overcome some of these challenges, making these motors even more effective and economical. Regardless, the Capacitor-Run Induction Motor remains an integral part of our daily lives, powering many appliances and systems we often take for granted.