Explore the working principle, construction, advantages, applications, and limitations of Capacitive Load Cells in this comprehensive article.

Introduction to Capacitive Load Cells

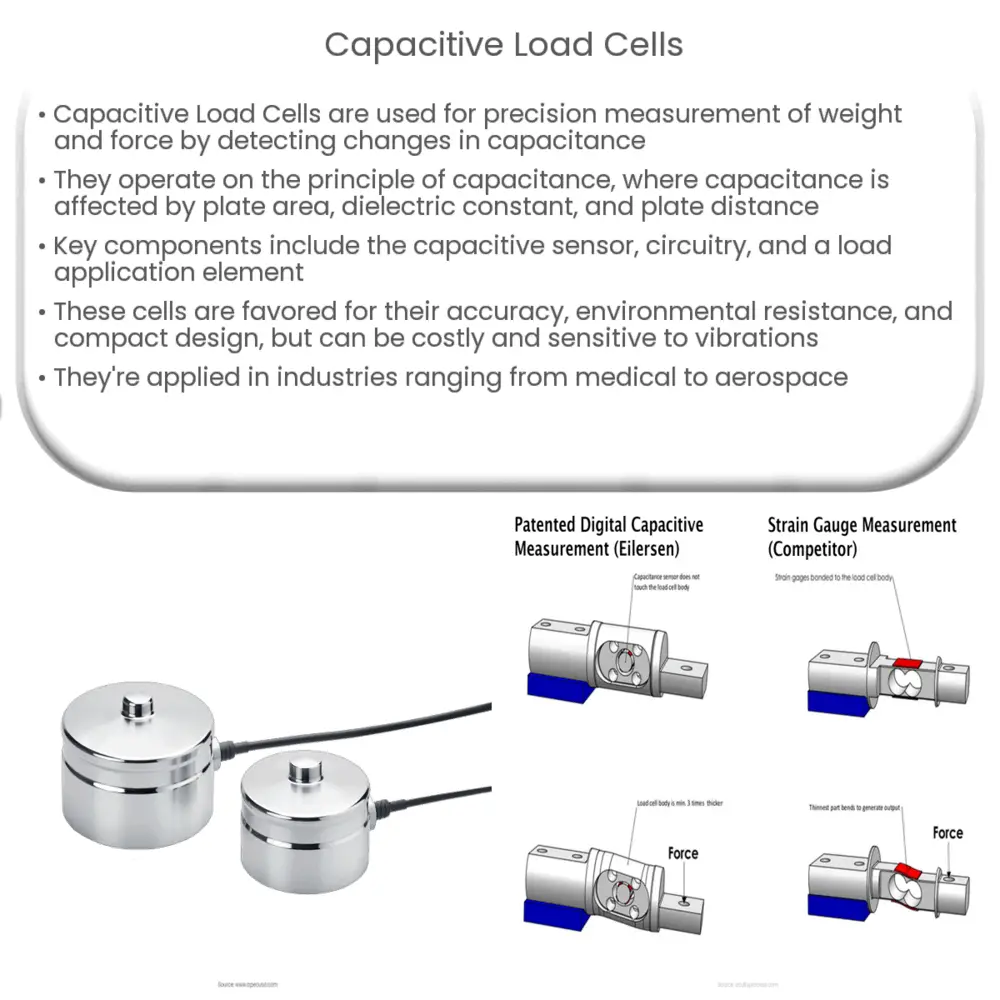

When it comes to precision measurement of weight and force, one of the crucial technologies employed is the Load Cell. Among the numerous types of load cells available, Capacitive Load Cells have become increasingly popular due to their unique properties and advantages. These devices measure force by detecting the change in capacitance.

Principle of Operation

A Capacitive Load Cell operates based on the basic principle of capacitance, which is the ability of a system to store an electrical charge. A typical capacitive load cell comprises two parallel plates with a dielectric material in between. The capacitance C of this system is directly proportional to the area A of the plates and the dielectric constant ε, and inversely proportional to the distance d between the plates:

C = εA/d

When a force is applied to the load cell, it induces a displacement which changes the distance d between the plates, thus altering the capacitance. This change in capacitance is detected and converted into a readable output.

Construction and Components

A Capacitive Load Cell is typically constructed with the following main components:

- Capacitive Sensor: This is the primary sensing element, comprised of a pair of parallel plates with a dielectric material sandwiched in between.

- Circuitry: This includes the electronic circuit for measuring the change in capacitance and converting it into an electrical signal.

- Load Application Element: This part transfers the applied force onto the capacitive sensor.

The structure of capacitive load cells can vary, but these are the basic components that are commonly present. By effectively applying the force to the capacitive sensor and accurately measuring the change in capacitance, these devices can provide precise measurements of force and weight.

Advantages of Capacitive Load Cells

There are several reasons why capacitive load cells are highly favored in various applications:

- High Accuracy: They offer high accuracy and repeatability in their measurements.

- Resistant to Environmental Conditions: Unlike other types of load cells, capacitive ones are highly resistant to temperature fluctuations and humidity, which makes them ideal for harsh environments.

- Compact and Lightweight: Capacitive load cells are often more compact and lighter than their counterparts, making them ideal for applications where space and weight are significant considerations.

Applications of Capacitive Load Cells

Due to their distinct features and capabilities, capacitive load cells find extensive use in various fields:

- Industrial Weighing: Their high precision makes them suitable for applications like batch weighing, bulk material weighing, and process control.

- Medical Devices: In medical field, these load cells are used in infusion pumps, dialysis machines, and surgical instruments to measure force accurately.

- Aerospace and Defense: Capacitive load cells are used in guidance systems, avionics, and other aerospace applications because of their compact size and resistance to environmental factors.

- Automotive Industry: These cells are employed in the testing of materials, engines, and other automotive parts.

Potential Limitations

Despite their numerous advantages, capacitive load cells do have some potential limitations that need to be considered:

- Cost: They can be more expensive than other types of load cells, which may limit their use in cost-sensitive applications.

- Vibration Sensitivity: Capacitive load cells can be sensitive to vibrations, which can affect their accuracy in certain environments.

- Need for Calibration: To maintain high accuracy, these load cells require regular calibration, which can add to the total cost of ownership.

Conclusion

In conclusion, capacitive load cells are a powerful tool for precise weight and force measurements in a variety of applications, from industrial processes to medical equipment and beyond. Their high accuracy, resistance to environmental conditions, and compact and lightweight design make them an ideal choice for many applications. However, as with any technology, they have potential limitations, such as cost, sensitivity to vibrations, and the need for regular calibration. Overall, understanding these characteristics and trade-offs is crucial when choosing the right load cell for a specific application.