Explore the workings, advantages, and applications of capacitive liquid level sensors in diverse industries and their key limitations.

Understanding Capacitive Liquid Level Sensors

The concept of measuring liquid levels might seem straightforward, but the diverse range of applications and varying conditions in which these measurements must be conducted often require specialized technology. Among these, capacitive liquid level sensors stand out for their versatility and effectiveness.

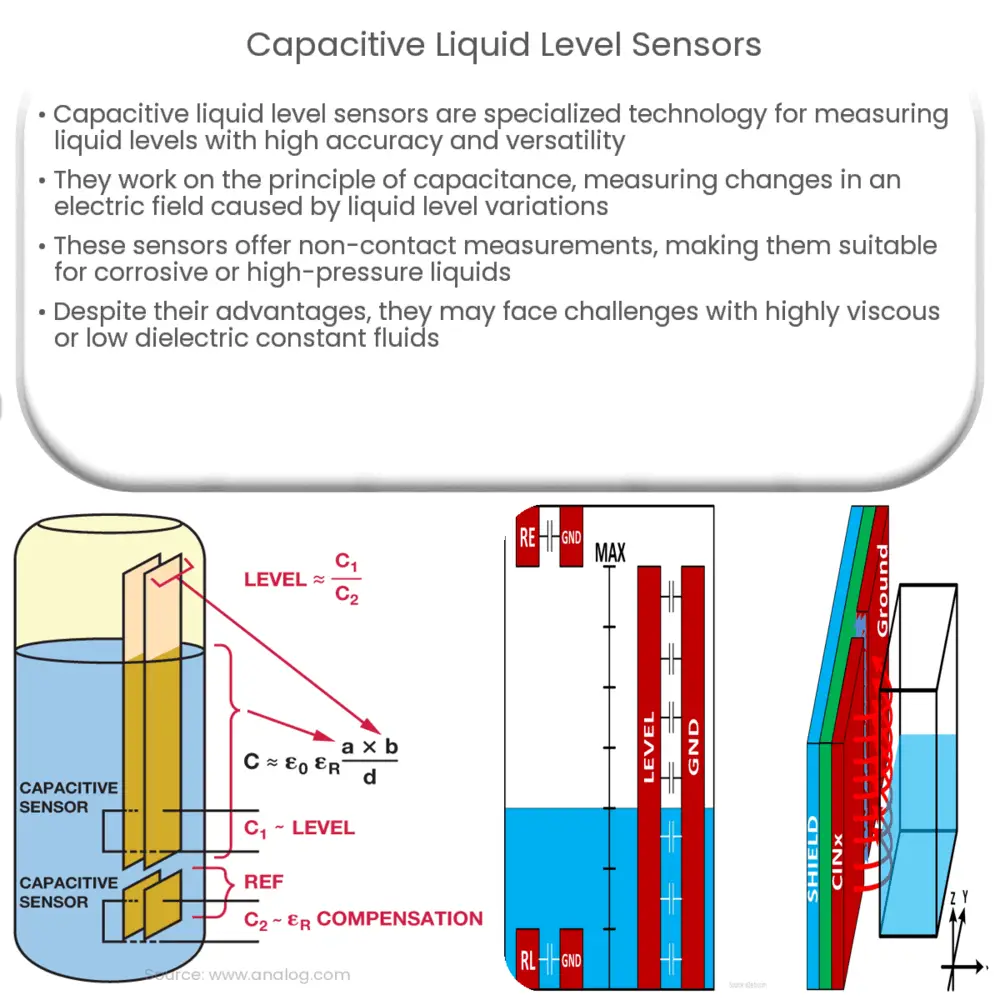

As the name implies, capacitive liquid level sensors utilize the principle of capacitance — the ability of a system to store an electrical charge. The sensors generate an electric field, then measure changes in this field caused by variations in the liquid level. Given the inherent properties of liquids and their effect on an electric field, these sensors provide highly accurate measurements.

Operation of Capacitive Liquid Level Sensors

Capacitive liquid level sensors operate by creating an electrical field between two electrodes. In a simple configuration, one of these electrodes might be a conductive plate, while the other could be the liquid itself. The liquid’s level relative to the conductive plate will determine the capacitance value, and hence, the sensor can interpret this value to provide a precise measurement of the liquid level.

This operation is largely based on a principle in physics known as Gauss’s Law for electric fields. This law, applied to capacitors, explains how the capacitance of a system depends on the dielectric constant (also known as relative permittivity) of the material separating the capacitor plates—in this case, the material is a combination of the liquid and air.

- Non-contact Measurement: Capacitive liquid level sensors can perform non-contact measurements. This is especially beneficial in conditions where the liquid in question may be corrosive or under high pressure, thus requiring minimal direct contact with the sensor.

- Versatility: The sensors are versatile in their application, being capable of measuring a wide variety of liquids, from water to oil and various chemical substances.

- High Accuracy: Due to their operation principle, capacitive sensors are often more accurate than their counterparts. They can measure liquid levels with minimal error, ensuring precision in applications where exact measurements are crucial.

Their high accuracy, versatility, and non-contact measurement capabilities make capacitive liquid level sensors an essential tool in numerous industrial and scientific applications.

Applications of Capacitive Liquid Level Sensors

Due to their high accuracy, non-contact measuring capability, and versatility, capacitive liquid level sensors are widely used in numerous industries and scientific endeavors. Some common applications include:

- Oil and Gas Industry: They are employed for precise level measurements in oil reservoirs, fuel tanks, and processing equipment, aiding in efficient operation and safety.

- Chemical Processing: These sensors can withstand corrosive substances and provide accurate measurements in chemical processing plants, thereby ensuring proper mixing of ingredients and maintaining process efficiency.

- Food and Beverage Industry: Used in vats, containers, and production lines to monitor levels of various liquids, ensuring quality control and efficient production.

- Water Treatment Facilities: These sensors help in monitoring water levels in tanks, reservoirs, and processing equipment, crucial for the management and efficient operation of water treatment facilities.

- Automotive Industry: Capacitive sensors also find usage in vehicles to monitor fuel levels, coolant levels, and other fluid levels, contributing to safe and efficient vehicle operation.

Limitations and Challenges

Despite their advantages, capacitive liquid level sensors do have certain limitations. For instance, they can struggle with accuracy in applications involving highly viscous or extremely low dielectric constant fluids. Additionally, while the sensors are usually resistant to changes in temperature and pressure, extreme conditions might impact their performance.

Conclusion

In conclusion, capacitive liquid level sensors are a valuable tool in an array of industries due to their unique operational principle and inherent advantages. They offer high accuracy, non-contact measurements, and versatility across a wide variety of liquids. These strengths, however, must be weighed against their limitations in certain conditions and with certain fluids. Nonetheless, as technology progresses and these sensors continue to evolve, their applicability and effectiveness will likely only increase. Understanding these sensors and their function is key to unlocking their full potential and making the most of their capabilities in various industrial and scientific applications.