Explore the world of cable trays, their types, materials, benefits, standards, and installation considerations for efficient cable management.

Introduction to Cable Trays

Cable trays are integral components in modern electrical and data cable management systems. They provide an effective and versatile solution for routing and organizing cables in a wide variety of applications.

Types of Cable Trays

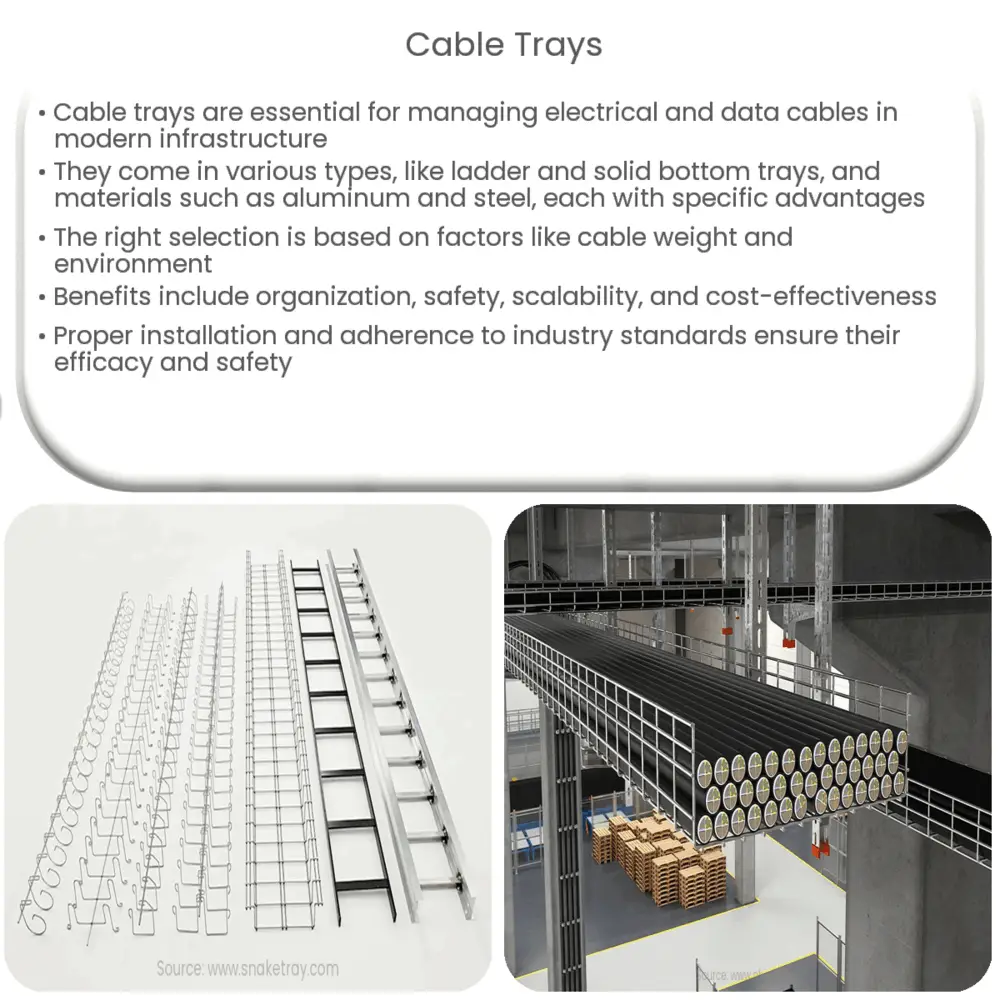

There are several types of cable trays, each designed to serve specific needs and environments. Understanding their unique characteristics is crucial in selecting the appropriate one for your needs. Let’s examine the main types:

- Ladder Cable Trays: These trays resemble a ladder, providing strong support for heavy cable loads while ensuring good ventilation. They allow for easy cable insertion and removal.

- Solid Bottom Cable Trays: Solid bottom trays provide maximum cable protection. They are typically used in applications where sensitive cables require additional safety from physical damage or external influences.

- Wire Mesh Cable Trays: These trays, made of steel wire mesh, are lightweight and flexible, ideal for installations where space and weight are a concern.

- Channel Cable Trays: Channel trays are the simplest form of cable trays – a single channel through which cables run. They’re often used for installations that require just a few cables.

Cable Tray Materials

Cable trays can be made from different materials, each offering distinct advantages. The selection often depends on the environment where they will be installed. The most commonly used materials include:

- Aluminum: Aluminum trays are lightweight, resistant to corrosion, and suitable for both indoor and outdoor applications.

- Steel: Steel trays are strong and durable, ideal for heavy-duty applications. However, they may require additional coatings for corrosion resistance.

- Stainless Steel: Stainless steel trays combine the strength of steel with excellent corrosion resistance, making them suitable for harsh environments.

- Fiberglass: Fiberglass trays are non-conductive and resistant to most chemicals, making them ideal for specific industrial applications.

Choosing the right cable tray involves considering factors like cable weight, environment, ease of installation, and cost. Understanding these aspects helps ensure that the installed system effectively meets the intended application’s requirements.

Benefits of Using Cable Trays

Cable trays offer numerous benefits that make them an appealing choice for cable management. Some of these advantages include:

- Organization and Ease of Access: Cable trays neatly organize cables and provide easy access for maintenance or modifications. This results in fewer hazards and a cleaner, more professional appearance.

- Increased Safety: By preventing the entanglement of cables and reducing the risk of electrical fires, cable trays can significantly enhance safety.

- Scalability: Cable trays allow for scalability and flexibility in managing cable systems. They can be easily extended, rerouted, or modified to accommodate changes or additions to the system.

- Cost-Effectiveness: Compared to other cable management systems, like conduits, cable trays can be more cost-effective in terms of both material cost and installation labor.

Cable Tray Standards

To ensure safety and performance, cable trays must meet certain standards. Organizations such as the National Electrical Manufacturers Association (NEMA) in the US and the International Electrotechnical Commission (IEC) globally set these standards. They cover areas like design, testing, and installation.

Installation Considerations

Proper installation of cable trays is critical to their effectiveness. Some considerations include:

- Load Capacity: The tray must be able to support the weight of the cables without sagging or collapsing.

- Spacing: Adequate spacing between trays must be maintained to prevent overheating and allow for maintenance access.

- Support: Trays must be properly supported and secured to prevent movement and reduce strain on the cables.

- Fill Rate: The amount of cable in a tray, or fill rate, should not exceed the recommended capacity to ensure safety and longevity.

Conclusion

In conclusion, cable trays are a fundamental part of modern infrastructure, playing a crucial role in the efficient and safe management of electrical and data cables. They come in various types and materials, offering a flexible and scalable solution for a wide range of applications. With proper selection, installation, and adherence to industry standards, cable trays can greatly enhance the functionality and safety of cable systems. As such, understanding their uses, benefits, and requirements is invaluable for anyone involved in building or managing infrastructure systems.