Buck converters are efficient DC-DC power converters that step down input voltage to a lower, regulated output voltage for various electronic devices.

Buck Converter: An Overview of Design, Operation, and Applications

Part 1: Introduction to Buck Converters and Their Design Principles

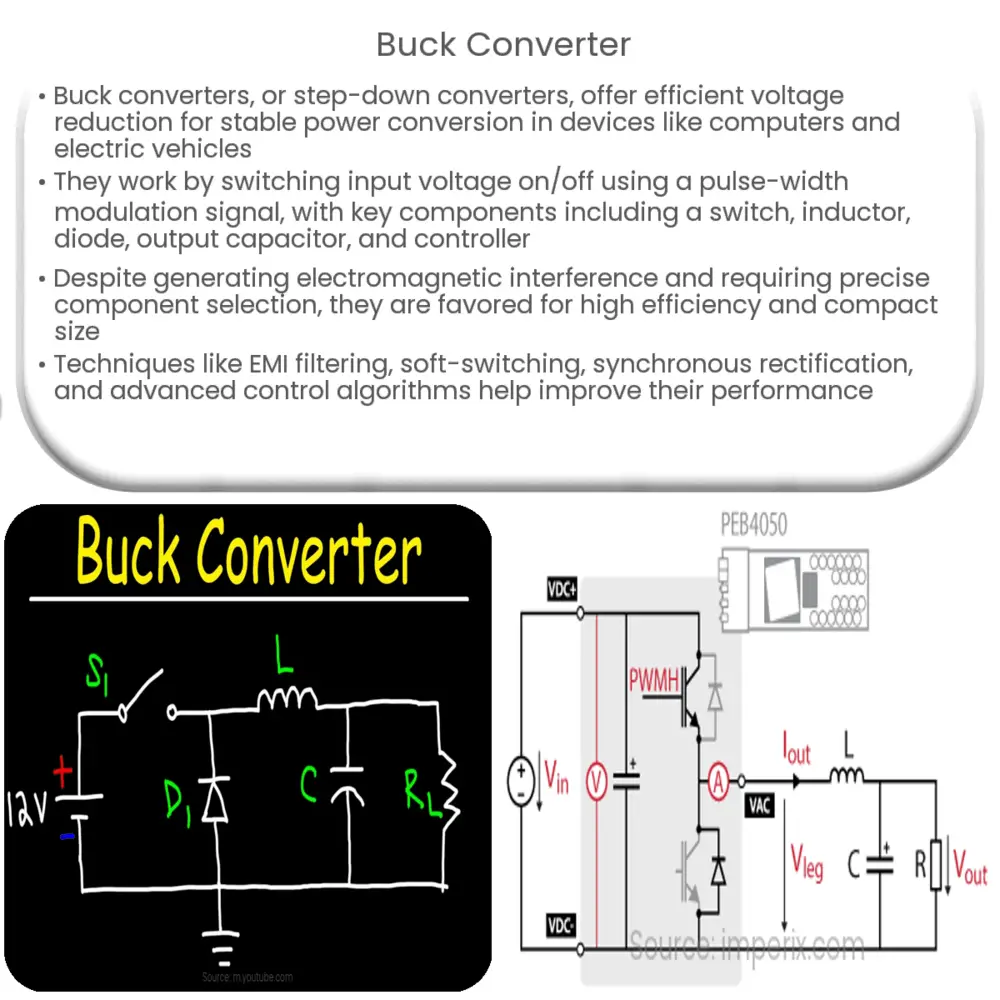

A buck converter, also known as a step-down converter, is a type of DC-DC power converter that efficiently reduces the input voltage to a lower, regulated output voltage. The primary goal of a buck converter is to maintain a constant output voltage despite variations in input voltage or load current. Buck converters are widely used in various electronic devices, such as computers, smartphones, and electric vehicles, where stable and efficient power conversion is essential.

Operation and Design of Buck Converters

Buck converters operate by switching the input voltage on and off through a series of components, including an inductor, diode, and capacitor. This switching action, controlled by a pulse-width modulation (PWM) signal, produces an average output voltage that depends on the duty cycle of the PWM signal. The duty cycle, defined as the ratio of the ‘on’ time to the total switching period, determines the proportion of the input voltage that is transferred to the output.

The primary components of a buck converter include:

- Input supply: The source of the DC voltage to be converted.

- Switch: A transistor, typically a MOSFET, that connects and disconnects the input voltage to the inductor.

- Inductor: An energy storage element that smoothens the current waveform and helps maintain a constant output current.

- Diode: A passive component that conducts current only in one direction, preventing the output capacitor from discharging back into the input supply when the switch is off.

- Output capacitor: A storage element that smoothens the output voltage waveform and filters out high-frequency noise.

- Controller: A circuit that generates the PWM signal based on feedback from the output voltage, regulating the output voltage by adjusting the duty cycle.

The performance of a buck converter is largely determined by the choice of components and the design of the control circuit. Key design parameters include the switching frequency, inductor value, output capacitor value, and the type of controller used. Selecting appropriate values for these parameters is crucial for achieving optimal efficiency, transient response, and output voltage stability.

Advantages and Limitations of Buck Converters

Buck converters offer several advantages over other types of DC-DC converters, such as linear regulators, including higher efficiency, smaller size, and lower heat dissipation. The high efficiency of buck converters, typically in the range of 90-95%, is particularly important for battery-powered devices, where maximizing battery life is a key consideration. Additionally, buck converters can deliver high output currents, making them suitable for a wide range of applications.

However, there are some limitations to using buck converters. They generate electromagnetic interference (EMI) due to their switching operation, which can potentially affect the performance of nearby sensitive circuits. Moreover, the complexity of the control circuit and the need for precise component selection can make the design process more challenging compared to simpler converter types.

Part 2: Applications of Buck Converters

Buck converters find applications in a diverse range of industries and devices. Some prominent use cases include:

- Power supplies: Buck converters are often used in power supplies for computers, servers, and telecommunication equipment, where stable and efficient voltage regulation is critical.

- Battery-powered devices: Portable electronics, such as smartphones, tablets, and laptops, use buck converters to extend battery life by efficiently converting the battery voltage to the required operating voltages for various subsystems.

- Electric vehicles: In electric vehicles, buck converters regulate the voltage supplied to different components, such as the motor controller, onboard chargers, and auxiliary systems, ensuring optimal performance and energy efficiency.

- Renewable energy systems: Solar and wind energy systems often employ buck converters to step down the generated voltage to the appropriate level for battery charging or grid integration.

- Industrial automation: In industrial control systems, buck converters provide stable and efficient power for sensors, actuators, and other equipment, enabling precise control and reliable operation.

Improving Performance and Reducing EMI in Buck Converters

There are several techniques to address the limitations of buck converters, particularly concerning electromagnetic interference (EMI) and design complexity. Some key strategies include:

- EMI filtering: Adding passive filters, such as LC filters, at the input and output of the converter can help reduce conducted EMI. Shielding the converter and using proper PCB layout techniques can also minimize radiated EMI.

- Soft-switching techniques: Implementing soft-switching techniques, such as zero-voltage switching (ZVS) or zero-current switching (ZCS), can reduce switching losses and EMI generation by minimizing voltage and current transients during the switching process.

- Synchronous rectification: Replacing the diode with a synchronous rectifier, typically a low-resistance MOSFET, can improve efficiency and reduce heat generation by minimizing the voltage drop across the rectifier during conduction.

- Advanced control algorithms: Implementing advanced control techniques, such as digital control or adaptive voltage positioning (AVP), can improve transient response and voltage regulation accuracy, simplifying the design process and reducing the need for precise component selection.

Conclusion

Buck converters play a vital role in modern electronics, providing efficient and stable voltage regulation for a wide range of applications. While they have some inherent limitations, such as EMI generation and design complexity, these can be mitigated through careful component selection, advanced control techniques, and proper EMI reduction strategies. As electronic devices continue to evolve and demand more efficient power conversion solutions, buck converters will remain a crucial component in powering our increasingly connected world.