Explore the workings, advantages, and disadvantages of Brushed DC Motors, their applications, and why they remain relevant today.

Introduction to Brushed DC Motors

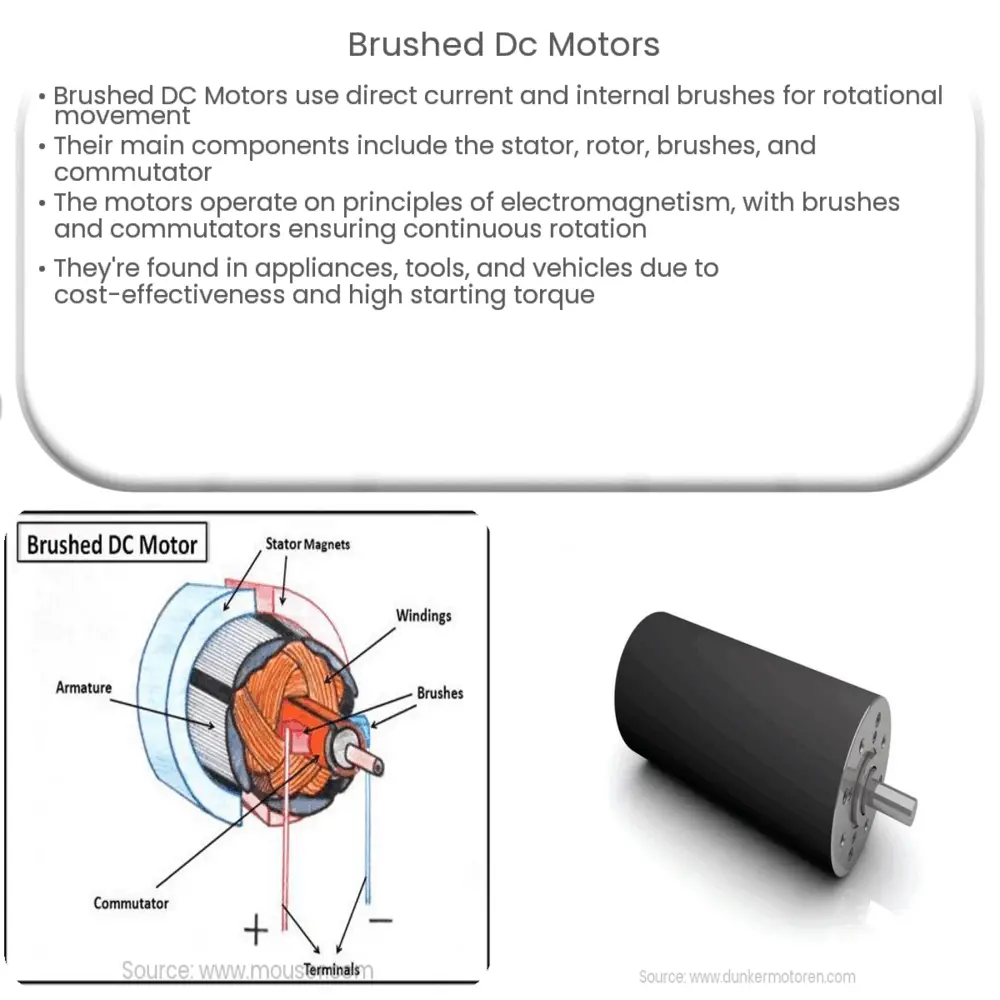

A Brushed Direct Current (DC) Motor is a type of motor that leverages direct current electricity and a system of internal brushes to generate rotational movement. Its simplicity and effectiveness have earned it a solid position in the array of electromechanical systems available to engineers.

Construction of Brushed DC Motors

Four main components primarily make up the construction of a Brushed DC Motor. These are:

- The stator

- The rotor, or armature

- The brushes

- The commutator

The stator provides a constant magnetic field, which is typically produced using permanent magnets or electromagnets. On the other hand, the rotor or armature is a set of windings where the input current gets introduced to generate a magnetic field. The brushes are made up of carbon or graphite, used for delivering current to the rotor. Lastly, the commutator is a mechanical rotary switch that periodically reverses the current direction between the rotor and the external circuit.

Working Principle

The working principle of a Brushed DC Motor is based on the fundamental concepts of electromagnetism and mechanics. The core principle relies on the interaction between magnetic fields. When an electric current is passed through the armature winding, a magnetic field is created. This magnetic field interacts with the magnetic field of the stator, creating a force that rotates the rotor.

Crucially, the commutator and brushes come into play here. As the rotor turns, the brushes maintain their position while the commutator segments slide underneath them. The result is a change in the polarity of the voltage and the direction of the current every time a new pair of commutator segments come into contact with the brushes. This process keeps the rotor turning in one direction.

One unique feature of Brushed DC Motors is the ability to control their speed easily and efficiently. The speed of these motors is directly proportional to the applied voltage. So, by increasing or decreasing the voltage, the speed of the motor can be adjusted accordingly.

Advantages and Disadvantages of Brushed DC Motors

Brushed DC motors offer numerous advantages. Some of the most notable include:

- Simple control characteristics: Brushed DC Motors have simple and effective speed and torque control. Simply controlling the voltage and current gives you control over the speed and torque, respectively.

- Low cost: Because of their simplicity in design and control, Brushed DC Motors are generally more cost-effective, especially for low-volume or single-unit applications.

- High starting torque: These motors provide a high starting torque, which is a crucial feature for applications that require a significant amount of force to start.

However, it’s also important to note some disadvantages of Brushed DC Motors:

- The brushes and the commutator wear over time, requiring maintenance and potential replacement.

- Brushes can create sparks, making these motors unsuitable for certain environments.

- Brushed DC Motors are less efficient than their brushless counterparts due to energy loss through the brush-commutator contact.

Applications of Brushed DC Motors

Despite some of the disadvantages, Brushed DC Motors are widely used in a range of applications. You can find them in home appliances, electric vehicles, power tools, toys, and more due to their cost-effectiveness and simplicity. Moreover, their high starting torque and straightforward control mechanism make them ideal for applications that demand quick starts, stops, and reversals.

Conclusion

In conclusion, Brushed DC Motors play an indispensable role in our daily lives, powering many devices and systems we often take for granted. Despite newer motor technologies emerging, like Brushless DC Motors, the simplicity, low cost, and high starting torque of Brushed DC Motors continue to make them a viable choice for numerous applications.

Understanding the working principles, advantages, and disadvantages of these motors helps in deciding the best motor type for a given application. As we move forward, the brushed DC motor will undoubtedly continue to play a significant role in the world of electromechanical systems.