Explore the workings, applications, and limitations of bimetallic temperature sensors, vital tools in temperature control and monitoring.

Introduction to Bimetallic Temperature Sensors

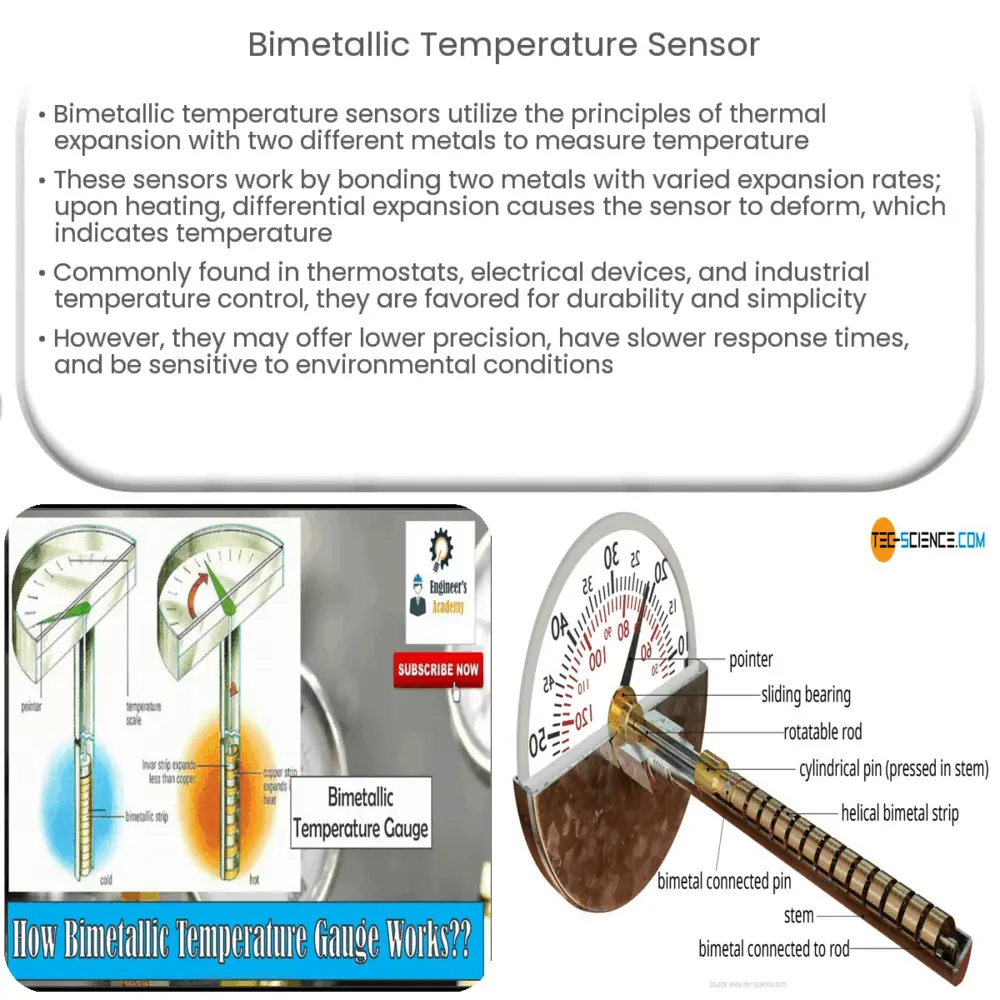

A bimetallic temperature sensor is a type of mechanical temperature sensor that utilizes the principles of thermal expansion to measure temperature. The term “bimetallic” refers to the sensor’s construction from two distinct metals, each possessing a different coefficient of thermal expansion.

Working Principle of Bimetallic Temperature Sensors

As a fundamental concept, when subjected to heat, different metals expand at various rates. This phenomenon is expressed quantitatively as a material’s coefficient of thermal expansion. Bimetallic temperature sensors leverage this principle by bonding together two metals with different expansion rates, forming a bimetallic strip or coil. When heat is applied, one metal expands more than the other, causing the strip or coil to bend or twist. This physical deformation can be used to measure temperature.

Design and Construction

The design of a bimetallic temperature sensor typically involves a bimetallic strip or coil mechanically linked to a temperature indicator or an electrical switch. In most cases, the strip is composed of steel and copper or steel and brass, owing to their significant difference in thermal expansion coefficients.

Applications of Bimetallic Temperature Sensors

Bimetallic temperature sensors find use in a wide array of applications due to their durability, simplicity, and cost-effectiveness. They are commonly employed in household appliances, industrial processes, and HVAC systems. Let’s delve into some of their specific applications:

- Thermostats: One of the most common applications of bimetallic sensors is in thermostats for controlling heating and cooling systems. The bending of the bimetallic coil or strip triggers a switch to turn the system on or off based on the temperature.

- Electrical Devices: In electrical devices, bimetallic sensors act as protective devices against overheating. When the device’s temperature rises above a certain threshold, the sensor triggers a switch to turn off the device, thus preventing potential damage.

- Industrial Temperature Control: In industries where maintaining specific temperatures is crucial, such as food and beverage or chemical processing, bimetallic temperature sensors can be utilized to monitor and control process temperatures.

Despite their extensive use, bimetallic temperature sensors are not without limitations. These include sensitivity to ambient conditions, slower response time compared to some other sensor types, and lesser precision than certain digital sensors.

Limitations and Considerations

While bimetallic temperature sensors are widely used due to their mechanical simplicity and robustness, they have limitations that make them less suitable for certain applications. These limitations primarily revolve around precision, response time, and sensitivity to environmental conditions.

- Precision: Compared to some electronic or digital sensors, bimetallic sensors generally offer lower precision. This is particularly true for applications requiring very precise, fine-grained temperature measurements.

- Response Time: Bimetallic sensors often have slower response times due to the time required for the heat to be transferred to the bimetallic strip or coil and for it to physically deform. This can be a drawback in scenarios where quick temperature changes need to be detected.

- Environmental Sensitivity: Bimetallic sensors can be influenced by environmental conditions, such as pressure or humidity, which might affect their accuracy. This makes them less suitable for applications in environments with rapidly changing or extreme conditions.

Conclusion

In conclusion, bimetallic temperature sensors, with their mechanical operation based on the principles of thermal expansion, have found widespread use across many industries and applications. Their simplicity, durability, and cost-effectiveness make them an excellent choice for many temperature sensing needs.

However, like any technology, they come with their own set of limitations, such as lesser precision, slower response times, and sensitivity to environmental conditions. Thus, the choice of temperature sensor must be carefully matched to the specific needs and conditions of the intended application. Despite these limitations, bimetallic temperature sensors remain a valuable tool in the field of temperature sensing and control, testament to the enduring power of simple, mechanical principles in our ever more digital world.