Shear force sensors measure tangential forces in various applications, including robotics, automotive, manufacturing, and healthcare.

Shear Force Sensor: An Overview

Introduction

Shear force sensors are devices that measure the force applied parallel to a surface, also known as the tangential force. These sensors have become an essential tool in various industries, including automotive, robotics, manufacturing, and healthcare. In this article, we will discuss the working principle of shear force sensors, their types, applications, and future prospects.

Working Principle

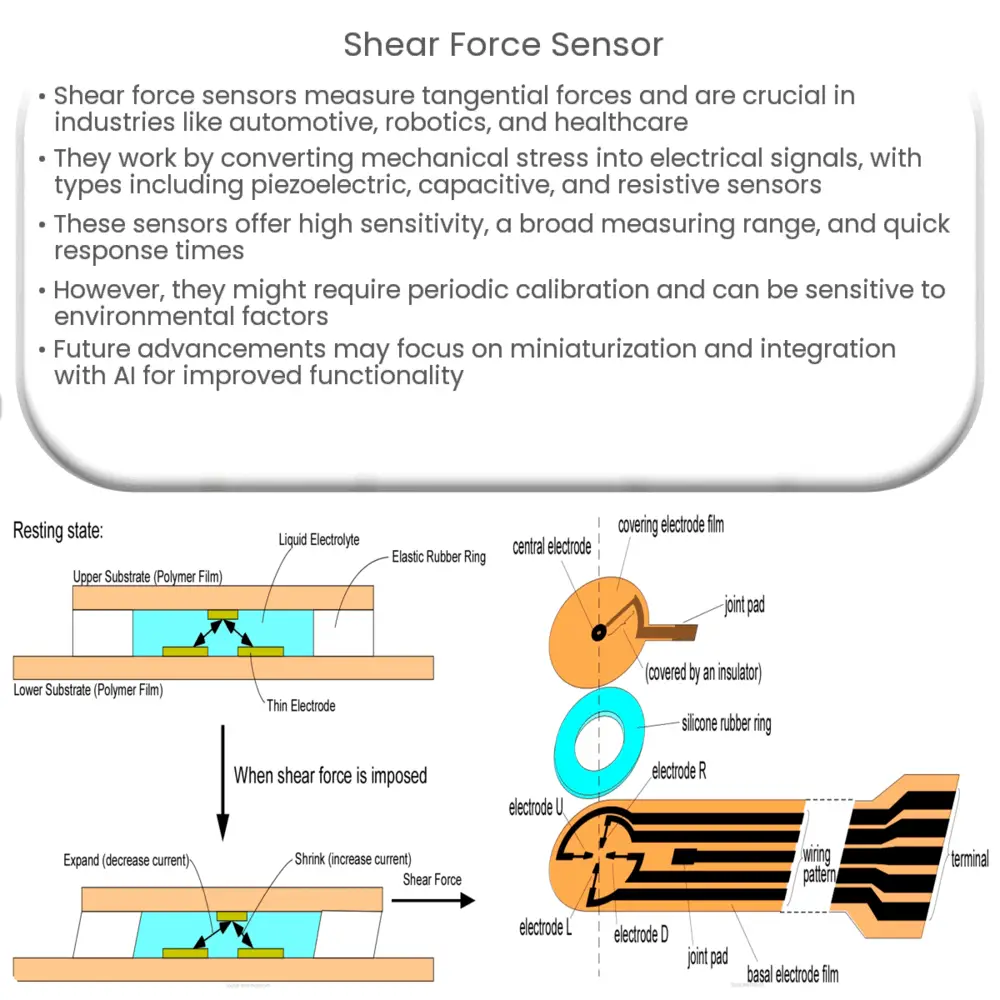

Shear force sensors operate based on the principle of converting mechanical stress into electrical signals. When a force is applied to the sensor, it causes deformation in its structure. This deformation is then translated into an electrical signal proportional to the applied force. There are several types of shear force sensors, each with its unique sensing mechanism, such as piezoelectric, capacitive, and resistive sensors.

Piezoelectric Shear Force Sensors

Piezoelectric shear force sensors consist of a piezoelectric material, which generates an electrical charge when subjected to mechanical stress. The generated charge is proportional to the applied shear force, allowing the sensor to measure the force accurately. These sensors are known for their high sensitivity, fast response time, and low power consumption.

Capacitive Shear Force Sensors

Capacitive shear force sensors measure force by detecting changes in capacitance between two conductive plates. When a shear force is applied, the distance between the plates changes, altering the capacitance. The change in capacitance is then converted into an electrical signal, which can be used to determine the applied force. Capacitive sensors are known for their high resolution and long-term stability.

Resistive Shear Force Sensors

Resistive shear force sensors operate based on the change in resistance of a sensing element when subjected to mechanical stress. These sensors typically use strain gauges or piezoresistive materials to measure the change in resistance. Resistive sensors are known for their robustness and cost-effectiveness, making them suitable for various applications.

Applications

Shear force sensors are employed in a wide range of applications due to their versatility and precision. Some of the most common uses include:

- Robotics: In robotics, shear force sensors are often integrated into robotic arms or grippers to measure the force exerted during manipulation tasks. This information helps the robot to perform tasks with precision and prevent damage to objects being handled.

- Automotive: Shear force sensors are used in various automotive systems, such as tire pressure monitoring, suspension control, and brake force measurement. These sensors help enhance vehicle performance, safety, and fuel efficiency.

- Manufacturing: In manufacturing, shear force sensors are employed to monitor and control various processes, such as cutting, grinding, and pressing. They help ensure product quality and minimize waste.

- Healthcare: In the healthcare sector, shear force sensors are used in prosthetics, orthotics, and rehabilitation devices. They help monitor and adjust applied forces to ensure patient comfort and proper functioning of the devices.

Advantages and Limitations

Shear force sensors offer several advantages, including:

- High sensitivity: These sensors can detect even minute changes in force, enabling precise measurements.

- Wide measuring range: Shear force sensors can measure a wide range of forces, making them suitable for various applications.

- Compact size: Many shear force sensors are compact and lightweight, allowing for easy integration into different systems.

- Fast response time: Shear force sensors typically have a rapid response time, enabling real-time measurements and control.

However, there are some limitations to consider:

- Sensitivity to environmental factors: Some shear force sensors may be affected by temperature, humidity, and electromagnetic interference, which can impact their accuracy.

- Calibration: Periodic calibration may be required to maintain the accuracy and reliability of the sensors.

- Cost: Some types of shear force sensors, such as piezoelectric sensors, can be relatively expensive, especially for high-precision applications.

Future Prospects

As technology advances, we can expect continued improvements in shear force sensor design and performance. Some potential developments include:

- Miniaturization: The development of smaller, more compact sensors will enable their integration into a wider range of applications, including wearable devices and medical implants.

- Improved materials: The use of new materials, such as graphene or advanced polymers, may lead to sensors with enhanced sensitivity, durability, and environmental resistance.

- Wireless connectivity: The integration of wireless communication technology into shear force sensors will facilitate remote monitoring and control, as well as real-time data analysis.

- Artificial intelligence: Combining shear force sensors with machine learning algorithms can enable advanced decision-making and automation capabilities in various industries.

Conclusion

Shear force sensors play a vital role in numerous applications across diverse industries, from robotics and automotive systems to healthcare devices. With ongoing advancements in materials, design, and connectivity, these sensors will continue to drive innovation and contribute to the development of smarter, more efficient, and safer systems. By understanding the working principles, advantages, limitations, and future prospects of shear force sensors, engineers and researchers can make informed decisions when selecting and implementing these devices in their projects.