A capacitive pressure sensor measures pressure by detecting changes in capacitance due to variations in the distance between conductive plates.

Introduction to Capacitive Pressure Sensors

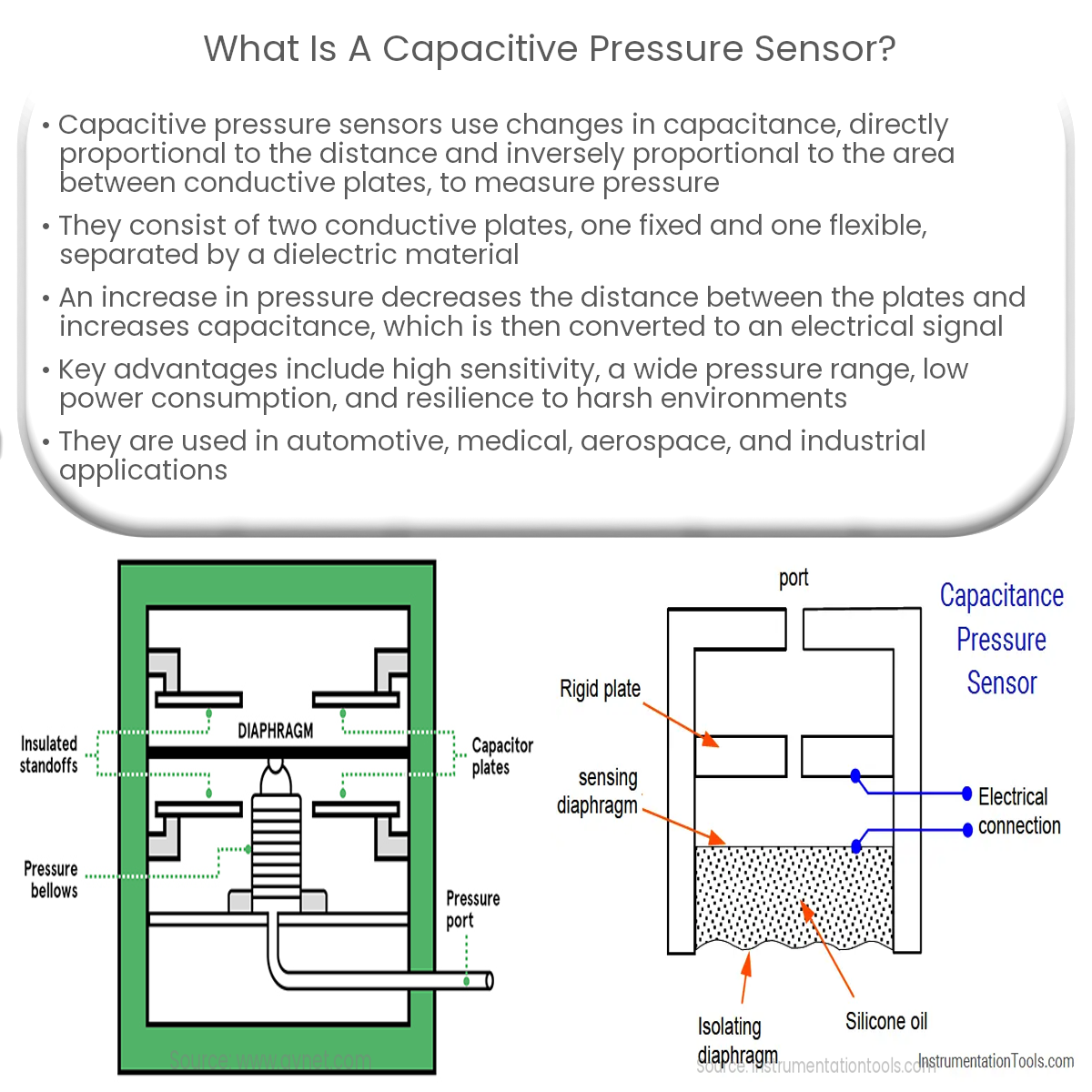

A capacitive pressure sensor is a type of sensor that utilizes the change in capacitance to measure pressure. It is based on the principle that the capacitance of a capacitor is directly proportional to the distance between the conductive plates and inversely proportional to the area of the plates. When a pressure is applied to the sensor, it results in a change in the distance between the plates, thus altering the capacitance.

Structure of Capacitive Pressure Sensors

Capacitive pressure sensors generally consist of two parallel conductive plates separated by a dielectric material. One plate is fixed, while the other is flexible, usually made of a thin metal diaphragm or a piezoelectric material. The dielectric material can be air, vacuum, or a solid insulating material such as glass, ceramic, or polymer. When pressure is applied to the flexible plate, it deforms, changing the distance between the plates, which in turn changes the capacitance.

Working Principle

As the pressure applied to the sensor increases, the distance between the conductive plates decreases, causing the capacitance to increase. Conversely, when the pressure decreases, the distance between the plates increases, and the capacitance decreases. The change in capacitance is then converted into an electrical signal, which can be measured and correlated to the applied pressure.

Advantages of Capacitive Pressure Sensors

- High sensitivity: Capacitive pressure sensors can detect very small changes in pressure due to their high sensitivity.

- Wide pressure range: These sensors can measure a wide range of pressures, making them suitable for various applications.

- Low power consumption: Capacitive pressure sensors require minimal power to operate, which is advantageous in battery-powered devices.

- Resistance to harsh environments: The sensors are resistant to high temperatures, humidity, and corrosive environments.

Applications of Capacitive Pressure Sensors

Capacitive pressure sensors find applications in a variety of industries, such as:

- Automotive: They are used to monitor tire pressure, fuel level, and engine oil pressure.

- Medical: In blood pressure monitoring, ventilators, and infusion pumps.

- Aerospace: To measure altitude, cabin pressure, and engine oil pressure.

- Industrial: For process control, leak detection, and hydraulic systems.