Explore the functioning, advantages, applications, and troubleshooting of vibrating level sensors in various industries.

Vibrating Level Sensors: An Overview

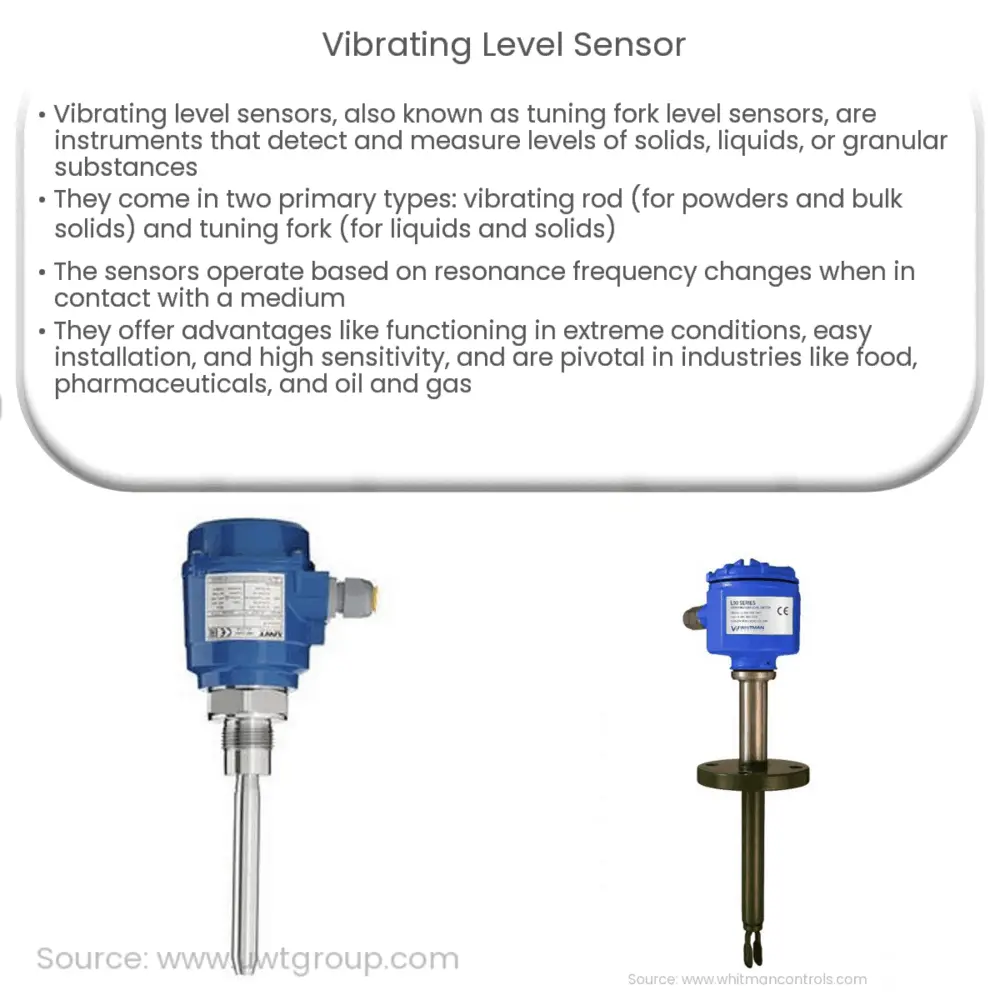

Vibrating level sensors, often also known as tuning fork level sensors, are versatile instruments used widely in various industries to detect and measure the level of solids, liquids, or granular substances. This technology represents a significant leap forward in level sensing, offering reliability, versatility, and precision.

There are two primary types of vibrating level sensors: vibrating rod and tuning fork. Each type of sensor offers its own set of advantages and is suited to specific applications.

- Vibrating Rod Sensors: These sensors are ideal for detecting the level of powders and bulk solids. They function by creating a mechanical vibration in a rod, changes in which are then used to determine the level of the substance being measured.

- Tuning Fork Sensors: Tuning fork sensors operate on a similar principle, but use a tuning fork-shaped probe. These sensors are used primarily for liquid level detection, but can also be used for solids.

Working Principle of Vibrating Level Sensors

The working principle of vibrating level sensors is based on the resonance frequency monitoring. When the sensor is surrounded by air, it vibrates at its natural frequency. However, when the medium (e.g., liquid, powder, or granular material) comes into contact with the sensor, it dampens the vibration. This change in vibration is detected and processed by the sensor’s electronics, signalling the presence of the medium at that level.

Advantages of Vibrating Level Sensors

Vibrating level sensors offer several distinct advantages over traditional level sensing technologies. These include their ability to function effectively in extreme conditions, ease of installation and minimal maintenance, high sensitivity, and the ability to provide continuous level monitoring.

- Function in Extreme Conditions: Vibrating level sensors are capable of operating in extreme conditions such as high pressure, temperature, or in the presence of steam, making them ideal for applications in harsh industrial environments.

- Easy Installation and Maintenance: These sensors are typically easy to install and require minimal maintenance due to their robust design and lack of moving parts.

This is just the beginning of the story of vibrating level sensors. As we delve deeper into their applications, installation, and troubleshooting in the next section, you’ll gain a more comprehensive understanding of their crucial role in modern industry.

Applications and Installation of Vibrating Level Sensors

Vibrating level sensors have a wide range of applications, including industries such as food and beverage, pharmaceuticals, chemicals, oil and gas, water and wastewater treatment, and many more. They are particularly useful in situations where other types of level sensors may fail due to coating, scaling, or foaming of the medium.

- Food and Beverage Industry: Vibrating level sensors are used in food and beverage manufacturing for tasks such as monitoring the level of grains in silos, or the level of liquids in tanks.

- Pharmaceutical Industry: These sensors are crucial for ensuring the proper fill levels of various containers and vessels in pharmaceutical manufacturing.

- Oil and Gas Industry: In the oil and gas industry, these sensors can detect the presence of different types of fluids in storage tanks and pipes, and monitor changes in their levels.

Installation of vibrating level sensors is typically straightforward. They can be mounted in various ways, such as on the side or top of a tank or silo, and are often designed for easy installation without the need for extensive modification of the existing infrastructure.

Troubleshooting Vibrating Level Sensors

While vibrating level sensors are typically very reliable, they can occasionally require troubleshooting. This usually involves checking for any physical damage, ensuring proper installation and alignment, and verifying that the sensor is correctly calibrated for the specific application.

- Physical Inspection: Check the sensor for any signs of physical damage. This could include cracks, bends, or other deformities that could affect its operation.

- Correct Installation: Ensure the sensor is installed correctly. Incorrect installation can lead to inaccurate readings.

- Calibration: The sensor should be calibrated for the specific medium it is designed to detect. Incorrect calibration can result in inaccurate level readings.

Conclusion

In conclusion, vibrating level sensors are an essential tool in many industries. They offer reliable, precise, and continuous level monitoring in a wide range of conditions, making them a versatile solution for various level sensing needs. Despite their sophisticated technology, they are relatively easy to install and maintain, and any potential issues can usually be identified and resolved through straightforward troubleshooting. As our industries continue to evolve and grow, it is clear that vibrating level sensors will continue to play a pivotal role in ensuring operational efficiency and safety.