Explore the world of torque motors: their key features, applications in various sectors, and their promising future in our increasingly automated world.

Torque Motors: A Comprehensive Guide

Torque motors, also known as direct-drive motors, have gained prominence in various sectors for their distinct characteristics and applications. They operate based on the principles of electromagnetism and feature high power density, high torque at low speeds, and excellent dynamic response.

Understanding Torque Motors

In simple terms, a torque motor is a specialized type of electric motor capable of creating a large amount of torque at relatively low rotational speeds. Unlike conventional motors, torque motors can run indefinitely while stalled, i.e., at zero speed, without overheating. This unique attribute makes them useful in applications that require a motor to hold a load steady for an extended period.

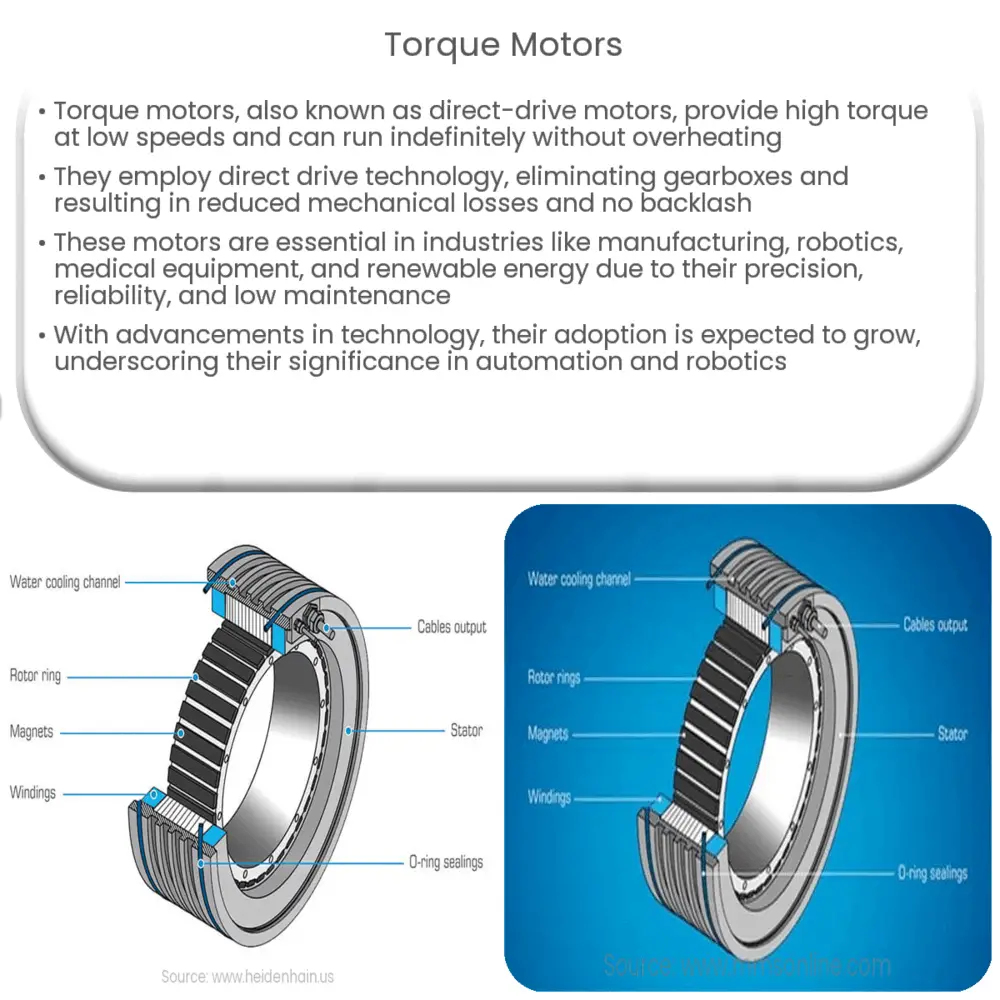

- Direct Drive Technology: As a subclass of synchronous motors, torque motors employ direct drive technology, eliminating the need for gearboxes or speed reducers. This direct transmission of power significantly reduces mechanical losses.

- Torque and Speed: Torque motors deliver high torque even at low rotational speeds, making them an ideal solution for applications requiring slow but powerful rotation.

- Cooling Mechanisms: Typically, torque motors are equipped with internal cooling systems to maintain optimum operating temperature, even when stalled or operating at low speeds.

Key Features of Torque Motors

- High Precision: Torque motors provide superior control, resulting in high-precision movements. This is particularly crucial in the manufacturing and robotics sectors.

- Low Maintenance: As they don’t require gearboxes or speed reducers, torque motors have fewer parts susceptible to wear and tear, leading to lower maintenance costs.

- No Backlash: Backlash, the brief moment of play or loss of motion that occurs when directions are reversed, is eliminated in torque motors because of their direct drive technology.

In conclusion, torque motors offer a myriad of advantages over traditional motors. They have revolutionized industries with their high precision, direct drive mechanism, and optimal performance even at low speeds. In the next section, we will delve into the diverse applications of torque motors and their impact on various sectors.

Applications of Torque Motors

Given their unique characteristics, torque motors find applications in a diverse range of industries. Here are some notable examples.

- Manufacturing Industry: Precision, reliability, and reduced downtime are paramount in manufacturing. Torque motors excel in these aspects, making them ideal for tasks such as conveyor belt control and CNC machine operation.

- Robotics: In robotics, high torque at low speeds combined with precision control is necessary. Torque motors fulfil these requirements, thus playing a significant role in the evolution of robotics.

- Medical Equipment: In the medical field, precision is a non-negotiable requirement. Torque motors are used in critical devices such as MRI machines, surgical robots, and precision scanners.

- Renewable Energy: Torque motors are also employed in the renewable energy sector. They drive mechanisms in wind turbines, owing to their ability to generate high torque even at low speeds.

Future of Torque Motors

The future of torque motors is promising. With continuous advancements in technology, these motors are expected to become even more efficient and compact. Given the increasing demand for automation, the adoption of torque motors is projected to rise in the coming years, further driving innovation and improvements.

Conclusion

Torque motors, with their high torque at low speeds, precision, and low maintenance costs, have become an essential component in various industries. Their versatility and performance have not only transformed existing applications but also unlocked new possibilities, especially in automation and robotics. The future holds immense potential for torque motors, promising an era of increased efficiency and reliability in electromechanical systems. Their role in industrial, medical, and renewable energy sectors reaffirms their growing importance in our increasingly automated world.