Thermal level sensors measure liquid levels using thermal conductivity principles, offering accuracy, low maintenance, and versatility in various industries.

Understanding Thermal Level Sensors: Applications and Advantages

Introduction

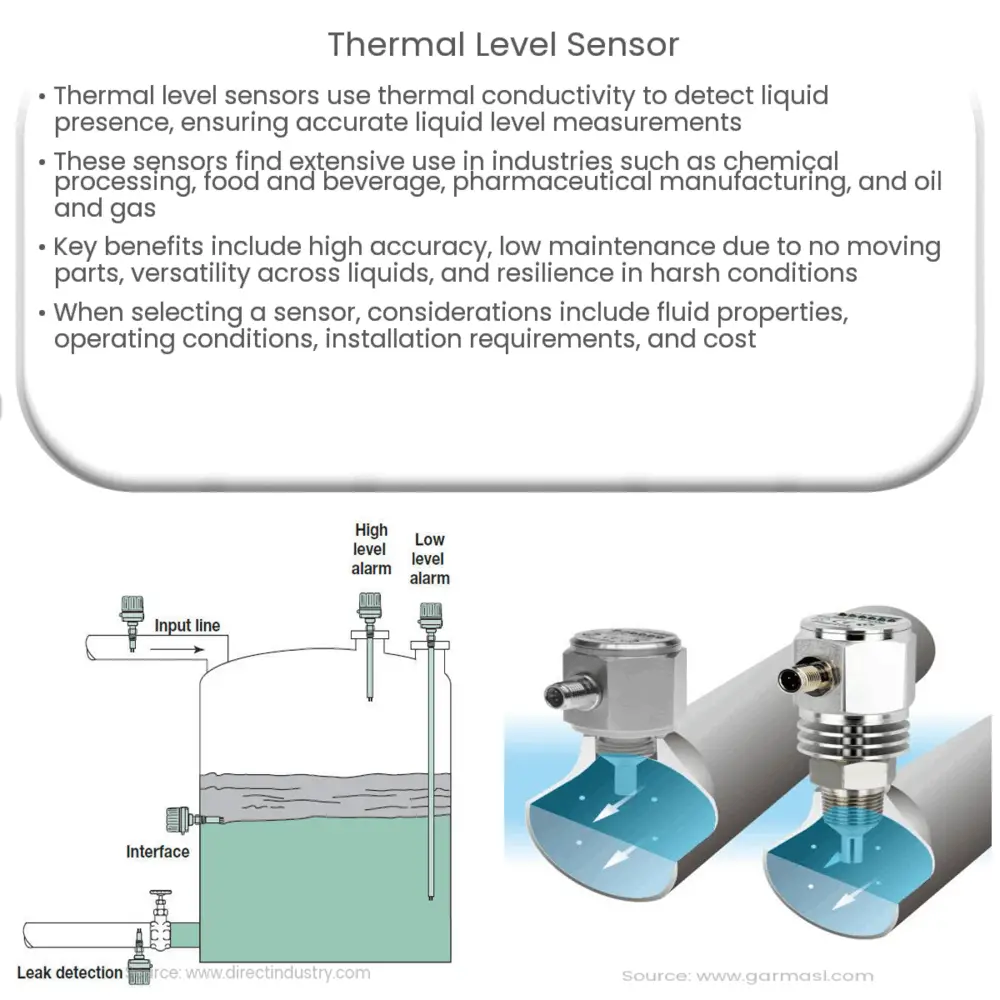

Thermal level sensors are essential tools used for measuring and monitoring liquid levels in a variety of industrial and commercial applications. These sensors employ the principles of thermal conductivity to determine the presence or absence of a liquid at a specific point. This article will explore the underlying technology, common applications, and the advantages of using thermal level sensors in different industries.

How Thermal Level Sensors Work

Thermal level sensors function based on the thermal conductivity properties of fluids. The sensor consists of a temperature-sensitive element, such as a thermistor or resistance temperature detector (RTD), and a heating element. Both are placed in close proximity to each other within a probe that is submerged into the fluid.

When the heating element warms up, it transfers heat to the temperature-sensitive element. The rate of heat transfer is dependent on the surrounding medium’s thermal conductivity. In the presence of a liquid, the heat transfer occurs at a faster rate compared to when the sensor is surrounded by air or gas. By measuring the temperature difference between the heating and temperature-sensitive elements, the sensor can determine if it is immersed in a liquid or not. This data is then used to indicate the level of the liquid in the container.

Common Applications of Thermal Level Sensors

Thermal level sensors are versatile and find use in a wide range of industries and applications. Some of the most common applications include:

- Chemical Processing: In chemical plants, accurate level monitoring is essential to maintain safety and prevent overflows, spills, and equipment damage. Thermal level sensors are suitable for use in these environments as they can withstand harsh chemicals and temperature fluctuations.

- Food and Beverage: Maintaining strict hygiene and sanitation standards is crucial in the food and beverage industry. Thermal level sensors are suitable for use in this sector as they have no moving parts and can be easily cleaned to prevent contamination.

- Pharmaceutical Manufacturing: Pharmaceutical processes often require precise level control for optimal performance and product quality. Thermal level sensors offer accurate and reliable measurements, making them ideal for use in this industry.

- Oil and Gas: Accurate level measurement is essential in the oil and gas industry to prevent accidents and equipment failure. Thermal level sensors are well-suited to this application as they can withstand extreme temperatures and pressure conditions.

Advantages of Thermal Level Sensors

There are several key benefits to using thermal level sensors for liquid level measurement, such as:

- Accuracy: Thermal level sensors provide precise and reliable measurements, even in challenging conditions or with varying fluid properties.

- Maintenance-free: These sensors have no moving parts, reducing the need for maintenance and the risk of mechanical failure.

- Versatility: Thermal level sensors can be used with a wide range of liquid types and can be easily adapted for different applications.

- Environmental resistance: These sensors are capable of withstanding harsh environments, including high temperatures, pressures, and corrosive chemicals.

Types of Thermal Level Sensors

There are two main types of thermal level sensors, each with its unique characteristics and advantages:

- Thermal Dispersion Level Sensors: These sensors rely on the difference in heat dissipation rates between the fluid and the surrounding air or gas. They are widely used in applications that require continuous level monitoring or point level detection.

- Infrared (IR) Thermal Level Sensors: IR sensors detect the presence of a liquid by measuring the infrared radiation emitted or absorbed by the fluid. They are ideal for applications that involve the detection of opaque liquids or those with low thermal conductivity.

Factors to Consider When Selecting a Thermal Level Sensor

When choosing a thermal level sensor for your application, it’s essential to consider the following factors:

- Fluid Properties: The thermal conductivity, viscosity, and chemical composition of the fluid can impact the sensor’s performance. Ensure the sensor is compatible with the specific fluid in your application.

- Operating Conditions: Consider the temperature, pressure, and environmental conditions the sensor will be exposed to. Select a sensor designed to withstand these conditions.

- Installation Requirements: Evaluate the available space and mounting options for the sensor. Some sensors may require specific installation configurations for optimal performance.

- Output and Connectivity: Choose a sensor with the appropriate output signal and communication protocols to ensure seamless integration with your existing control systems.

- Cost and Maintenance: Consider the initial cost, ongoing maintenance requirements, and the sensor’s lifespan to determine the overall cost of ownership.

Conclusion

Thermal level sensors are a reliable and accurate solution for monitoring and measuring liquid levels in various industries and applications. These sensors offer numerous advantages, including precision, low maintenance, versatility, and resistance to harsh environments. By understanding the principles behind thermal level sensors, their applications, and the factors to consider when selecting a sensor, you can make an informed decision for your specific needs.

In conclusion, thermal level sensors are an excellent choice for liquid level measurement in a wide range of industries. Their accurate and reliable performance, coupled with their ability to withstand challenging environments, make them an indispensable tool for ensuring the safe and efficient operation of numerous industrial processes.