Explore the function and importance of static charge neutralizers, their different technologies, and applications in various industries.

Understanding Static Charge Neutralizers

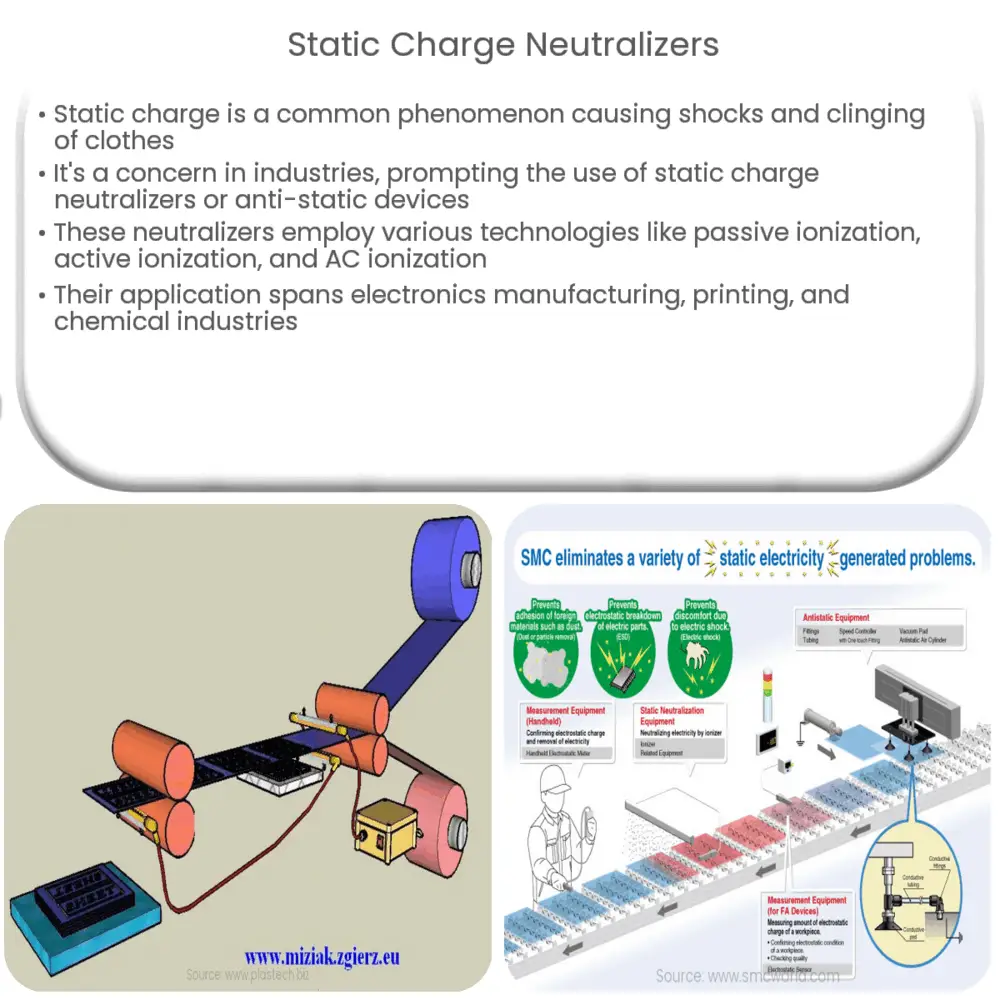

Electrical static charge is a physical phenomenon we encounter in various situations. From experiencing a shock when touching a metal object after walking on a carpet to the cling of clothes fresh out of the dryer, it’s all due to static electricity. While it may be mildly inconvenient or surprising in our daily lives, it can become a serious issue in certain industries. This is where static charge neutralizers, also known as anti-static devices, play a critical role.

The Mechanism of Static Electricity

Before diving into the function and importance of static charge neutralizers, let’s first understand the mechanism of static electricity. Static electricity is generated when two different objects come in contact, and electrons are transferred from one object to another. This process, known as ‘tripping,’ leaves one object with an excess of electrons (negative charge), and the other with a deficiency (positive charge).

When the charged object comes into contact with a conductive material, electrons rush to or from the object, causing a sudden, rapid discharge of electricity. This discharge is what we commonly refer to as a ‘static shock.’

The Role of Static Charge Neutralizers

Static charge neutralizers work by bringing a charged object back to a neutral state. They achieve this by adding or removing the right amount of electrons to balance the charge. These devices employ different technologies, such as passive ionization, active ionization, and electrical AC ionization, to name a few.

- Passive Ionization: This method uses a naturally radioactive material to produce ions. The material, typically Polonium-210, emits alpha particles that ionize the surrounding air, producing a cloud of both positive and negative ions that neutralize the static charge.

- Active Ionization: This process involves the use of an electric current to generate ions. The ionizer applies a high voltage to a sharp point, and the strong electric field around the point causes the surrounding air to ionize, creating positive and negative ions.

- Electrical AC Ionization: AC ionizers use alternating current to create positive and negative ions from air and gas. The device oscillates between generating positive and negative ions, ensuring a balance and thus neutralizing the static charge.

Applications of Static Charge Neutralizers

Static charge neutralizers are utilized across a wide array of industries, particularly those where static electricity could be detrimental to product quality or even pose a safety risk. Here are a few applications:

- Electronics Manufacturing: In electronics manufacturing, static charges can damage sensitive components, disrupt production, and affect product quality. Thus, anti-static devices are commonly used in production and assembly areas to prevent electrostatic discharge.

- Printing and Packaging: Static electricity can cause materials to stick together, attract dust, or result in uneven application of inks, coatings, or laminates. Neutralizing the static charge can help avoid such problems and improve the overall quality and efficiency of the process.

- Chemical and Gas Industries: In industries that deal with flammable substances, static electricity can be extremely dangerous, potentially igniting vapors and causing explosions. Therefore, static charge neutralizers are crucial for maintaining safety in these environments.

Choosing the Right Static Charge Neutralizer

The choice of a static charge neutralizer depends on several factors, such as the nature and size of the objects to be neutralized, the level of static charge, the speed of the process, and specific environmental conditions. While passive ionizers might be a good fit for slow processes and small objects, active or AC ionizers might be more effective for high-speed processes or larger surfaces.

Conclusion

In conclusion, static charge neutralizers play a crucial role in various industries, mitigating the risks and issues associated with static electricity. These devices work by balancing the electric charge on objects, employing different technologies such as passive ionization, active ionization, and electrical AC ionization. As static electricity can disrupt production, affect product quality, and even pose significant safety risks, the value of these neutralizers cannot be overstated. When selecting a static charge neutralizer, it is important to consider the specific requirements of the application, as well as the characteristics of the different available technologies.