Explore the workings, applications, and limitations of shaded-pole induction motors, and discover their future prospects in our detailed guide.

Introduction to Shaded-Pole Induction Motors

A Shaded-Pole Induction Motor is a type of AC motor known for its simple construction and reliable operation. Being the simplest and most inexpensive among all other types of induction motors, it plays a significant role in a variety of low-torque applications.

Construction and Working Principle

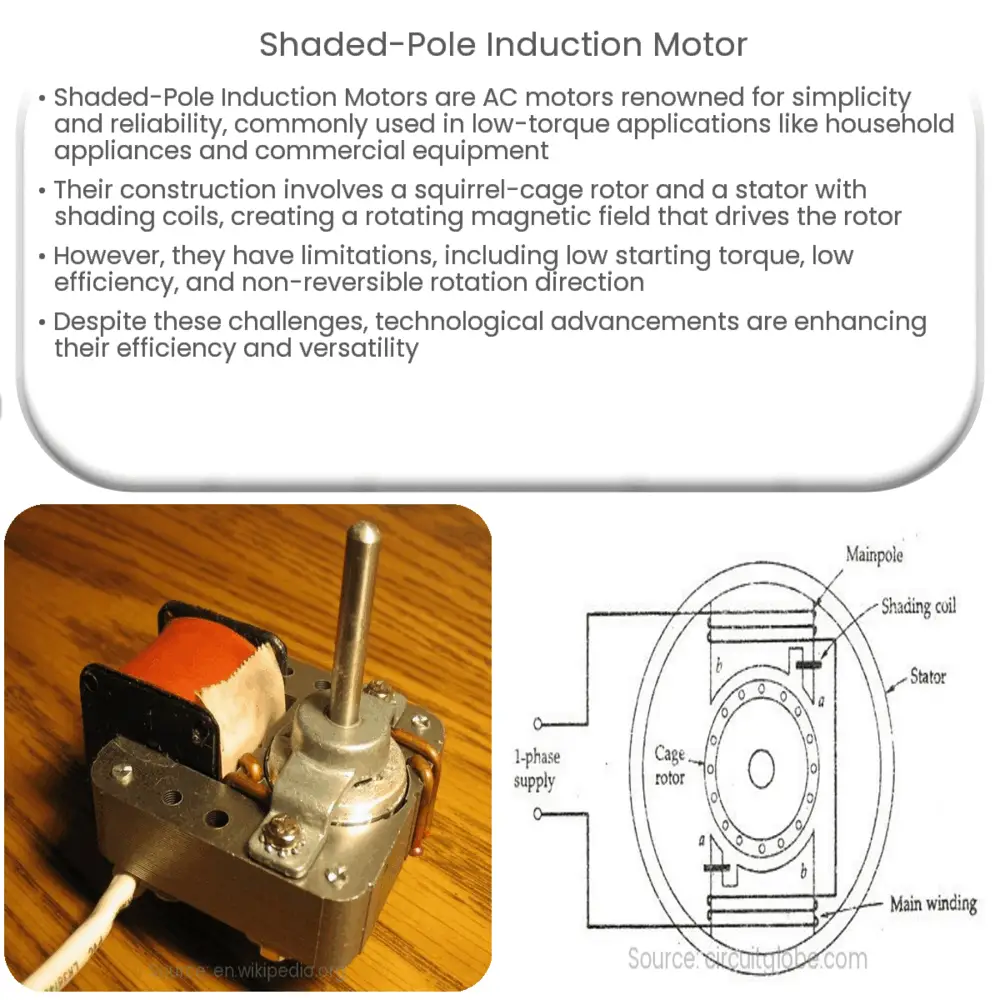

At the core of the shaded-pole induction motor are its main components: the squirrel-cage rotor and the stator. The stator, or stationary part, has salient poles, each with an additional winding known as the shading coil.

- The Squirrel-Cage Rotor: This component is similar to the rotor found in other types of induction motors. It is built from laminated iron cores with shorted ends, creating a ‘cage’ effect, hence the name.

- The Stator: The stator has salient poles, each equipped with a copper ring or shading coil at one part. This shaded portion of the pole creates a phase difference, crucial for motor operation.

As the AC supply is connected to the motor, a magnetic field is produced in the stator’s winding. Because of the shading coils, a phase difference is created between the fluxes in the shaded and unshaded parts of the poles. This phase difference causes the magnetic field to shift across the pole face from the unshaded portion to the shaded portion, resulting in a rotating magnetic field. The rotor, following the principle of electromagnetic induction, starts to rotate.

Applications

The shaded-pole induction motor is commonly used in a multitude of applications where high torque is not a requirement but simplicity and cost-effectiveness are. These applications range from household appliances to commercial equipment.

- Household Appliances: Shaded-pole motors are found in electric fans, hairdryers, small water pumps, and more.

- Commercial Equipment: They are also used in commercial devices like photocopy machines, film projectors, and record players.

Despite their widespread use, shaded-pole induction motors have their limitations, including low efficiency and low starting torque. These issues will be discussed in detail in the next section.

Limitations of Shaded-Pole Induction Motors

While shaded-pole induction motors have their distinct advantages, such as simplicity and cost-effectiveness, they are not without their limitations. These limitations are primarily due to the motor’s construction and operating principle.

- Low Starting Torque: The shaded-pole induction motor’s starting torque is relatively low compared to other types of induction motors. This characteristic restricts its use in applications that require a high starting torque.

- Low Efficiency: The efficiency of shaded-pole motors is generally low, especially in larger sizes. The reason is that a significant amount of power is lost in the copper losses of the shading coil.

- Direction of Rotation: The direction of rotation is not reversible by just reversing the supply connections. The construction of the motor dictates the rotation direction, limiting its adaptability in certain applications.

Advancements and Future Prospects

Despite these limitations, technological advancements are paving the way for the evolution of shaded-pole induction motors. Efforts are being made to increase their efficiency and make them more versatile. For instance, energy-efficient shaded-pole motors are being developed to reduce energy consumption and minimize environmental impact.

Conclusion

In conclusion, the shaded-pole induction motor, with its simple construction and cost-effectiveness, holds a significant place in the world of low-torque applications. Its presence in many household and commercial appliances is a testament to its value. Although it has limitations in terms of efficiency and starting torque, ongoing technological advancements promise an improved and more sustainable future for these motors. Understanding its working principles, advantages, and limitations is crucial for selecting the right motor for a specific application and for harnessing its full potential in the most effective way.