Explore the fundamentals of rotary encoders, their types, working principles, applications, challenges, and future prospects in our comprehensive guide.

Introduction to Rotary Encoders

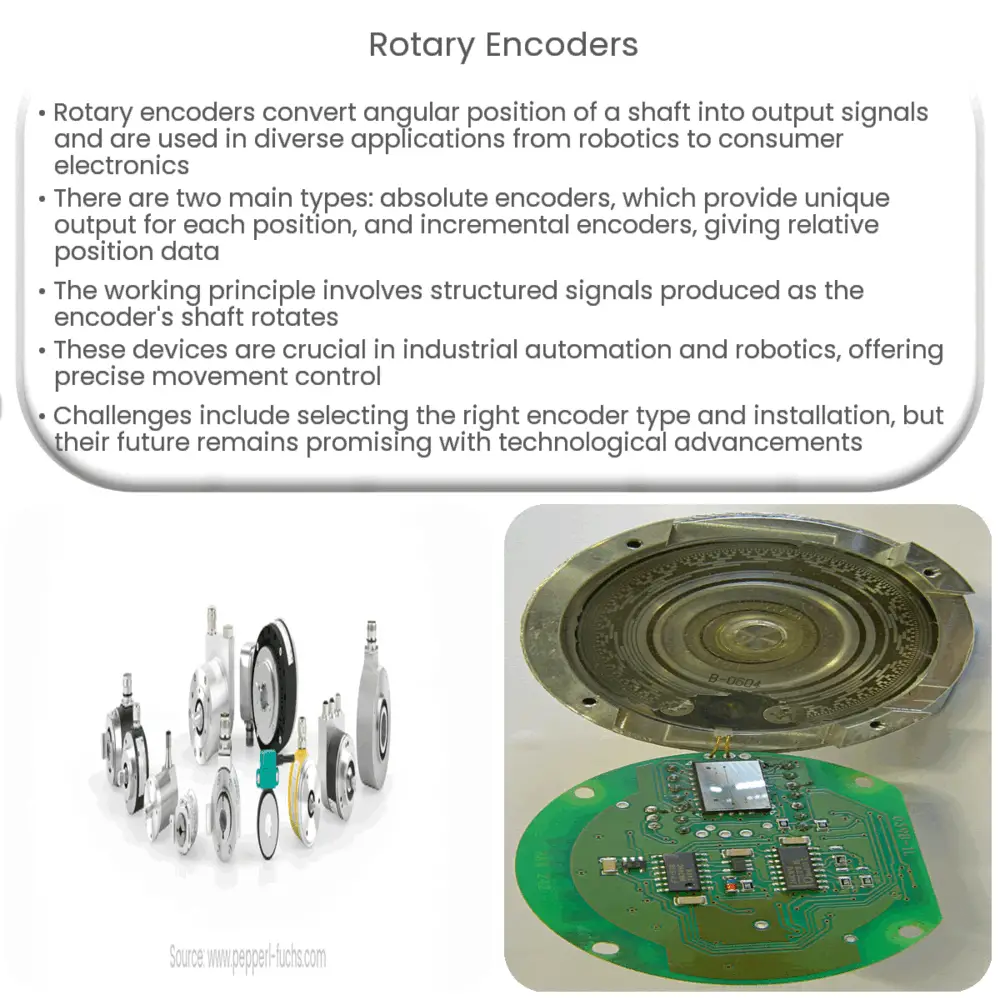

A rotary encoder, also known as a shaft encoder, is a type of sensor that converts the angular position or motion of a shaft or axle into an analog or digital output signals. These highly versatile devices are commonly found in a broad range of applications, from industrial controls to robotics, and even in consumer electronics.

Types of Rotary Encoders

There are primarily two types of rotary encoders: absolute and incremental.

- Absolute Rotary Encoders: These encoders provide a unique output for each position of the shaft, which means they can instantly determine the exact position of the shaft even after power loss.

- Incremental Rotary Encoders: These encoders provide relative position information, where the feedback depends on the movement from a known position. They typically include a “zero” position which allows them to be accurately positioned upon power-up.

Working Principle of Rotary Encoders

Rotary encoders operate based on a simple principle: as the encoder’s shaft rotates, it triggers a series of structured signals. These signals are then processed to produce a binary output that represents the shaft’s position.

The primary components of a rotary encoder include a disc, a light source, and a light detector. The disc, attached to the rotating shaft, has opaque and transparent sectors. The light source, positioned on one side of the disc, emits light towards the light detector on the other side. As the disc rotates, the light detector records the changing light levels and generates a corresponding signal pattern.

Applications of Rotary Encoders

Rotary encoders are used in a wide variety of applications due to their ability to provide precise and accurate rotational information. Some of these applications include:

- Industrial Automation: In various automated manufacturing processes, rotary encoders are used to control the movement and positioning of machinery.

- Robotics: In robotics, they’re utilized for precise control of the movement of robots, including their arms, wheels, and other components.

Despite their widespread use, the understanding and selection of the appropriate type of rotary encoder can be a complex task due to the variety of encoder configurations and output types. The second part of this article will delve deeper into these aspects, as well as potential challenges in using rotary encoders and the future prospects of this technology.

Encoder Configurations and Output Types

The configuration of a rotary encoder is largely determined by its intended application. For instance, some encoders are designed to withstand harsh environments, while others are designed for high precision applications.

Rotary encoders also differ in their output types. Some produce a simple binary output, while others produce a more complex Gray code output that reduces the chance of errors. Yet others produce an analog signal that can be easily integrated with conventional control systems.

Challenges in Using Rotary Encoders

While rotary encoders are incredibly useful devices, they are not without their challenges. The primary challenge lies in choosing the right type of encoder for a specific application. This involves understanding the nuances of absolute and incremental encoders, and knowing when to use each type. Additionally, the physical installation and alignment of the encoder can be a critical factor in its performance and lifespan.

Future Prospects of Rotary Encoders

Rotary encoders have seen significant advancements in recent years, and this trend is expected to continue. With the rise of Industry 4.0 and the Internet of Things (IoT), there is an increasing demand for devices that can provide real-time, accurate feedback in a variety of industrial applications. As such, rotary encoders are expected to play a crucial role in these developments.

Conclusion

In conclusion, rotary encoders are fundamental components in numerous applications, providing precise, real-time feedback on the position and movement of mechanical systems. Whether in industrial automation, robotics, or consumer electronics, these devices play a pivotal role in the operation and control of a wide array of machinery and equipment.

While they come with their set of challenges, the future of rotary encoders looks bright, spurred by technological advancements and the increasing demand for real-time, accurate feedback mechanisms. As we continue to embrace automation and digitization, the importance and relevance of rotary encoders in various sectors are only set to increase.