Explore the workings, features, applications, and future advancements of Pellistor gas sensors in our comprehensive guide to industrial safety.

Pellistor Gas Sensors: An Overview

Pellistor gas sensors are a type of gas detector used to measure concentrations of combustible gases. These sensors have been employed in a variety of industrial and environmental applications, ensuring the safety and efficiency of operations.

Working Principle

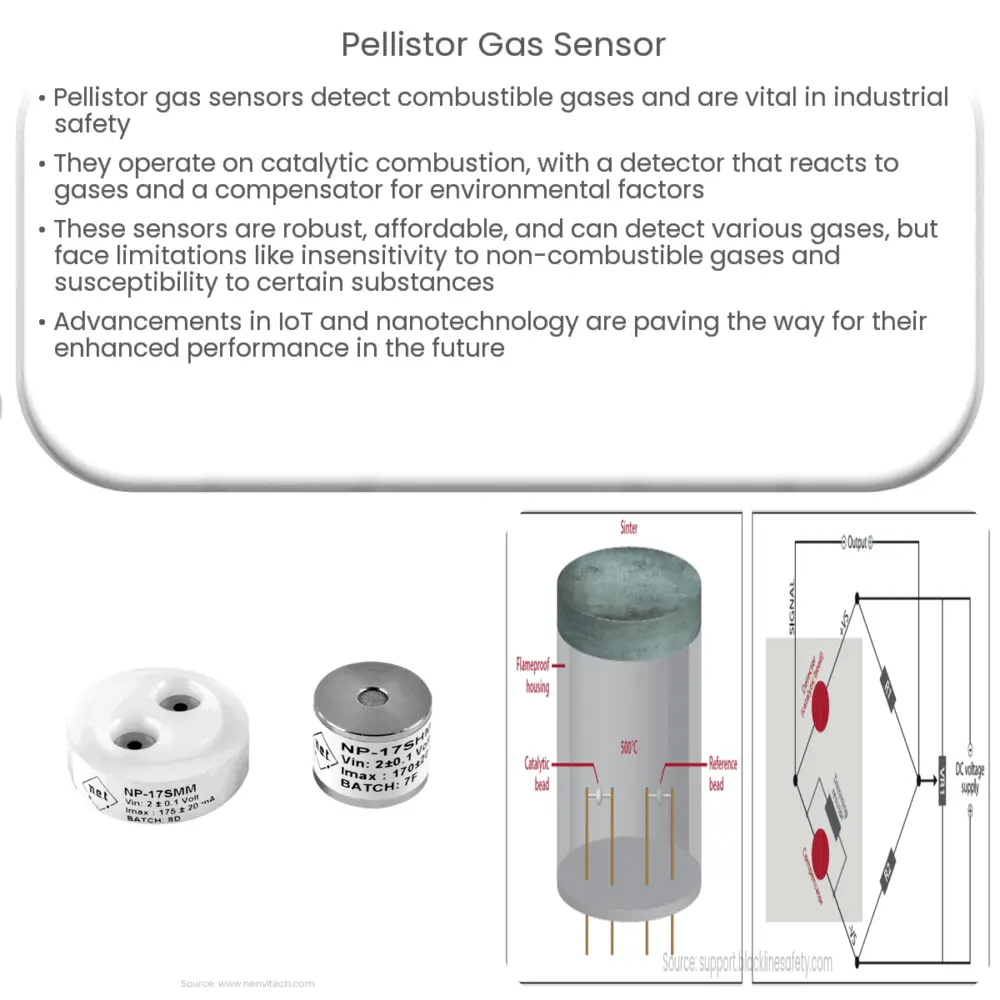

Pellistor sensors function based on the principle of catalytic combustion. They consist of two elements: a detector and a compensator, both of which are usually constructed as a matched pair. The detector contains a catalytic material, while the compensator is inactive.

- Detector: The detector element is coated with a catalyst that initiates a combustion reaction when exposed to a combustible gas. This process generates heat, causing an increase in the element’s temperature and, consequently, its resistance.

- Compensator: The compensator element, on the other hand, is designed to remain unaffected by the presence of combustible gases. It compensates for environmental factors such as humidity or temperature, which can also cause resistance changes in the detector element.

Key Features and Applications

Pellistor sensors offer several key features that make them suitable for specific applications. They are particularly known for their robustness, wide range of detectable gases, and affordability.

- Robustness: Pellistor sensors are built to withstand harsh industrial environments. They can operate in high temperatures and are resistant to a variety of physical stresses.

- Wide Detection Range: Pellistor sensors can detect a broad spectrum of combustible gases, making them versatile tools in gas detection.

- Affordability: Compared to other types of gas sensors, pellistor sensors are relatively inexpensive, contributing to their widespread use in industrial safety applications.

Limitations

Despite their numerous advantages, pellistor sensors do have certain limitations. They are not suitable for detecting non-combustible gases or those that do not catalyse at the sensor’s operating temperature. Furthermore, they can be poisoned or inhibited by certain substances, which limits their lifespan and reliability.

Pellistor sensors are also susceptible to changes in oxygen levels. A low oxygen environment can prevent the catalytic combustion process from occurring, resulting in a failure to detect the presence of combustible gases.

Advancements and Improvements

In recent years, efforts have been made to improve the performance and reliability of pellistor sensors. Researchers have been experimenting with various catalyst materials to enhance the sensor’s sensitivity and selectivity. Furthermore, developments in microelectronics have allowed for miniaturisation, reducing the size and power requirements of these sensors while improving their response times.

Pellistor Sensors in the Future

As the need for safety in industrial environments continues to grow, so does the demand for reliable and accurate gas detection systems. Pellistor sensors, with their affordability and robustness, will likely continue to play a significant role in this field. However, ongoing research and development are essential to mitigate their limitations and enhance their capabilities.

- Internet of Things (IoT): With the advent of IoT, the integration of pellistor sensors in connected devices can enable real-time monitoring and alert systems, enhancing safety protocols.

- Nanotechnology: The use of nanotechnology can improve the sensitivity and selectivity of pellistor sensors, allowing for the detection of gases at lower concentrations and minimizing false alarms.

Conclusion

Pellistor gas sensors, owing to their robustness, wide detection range, and affordability, have made a significant contribution to industrial safety. Despite their limitations, continuous advancements in technology and research promise to enhance their performance and versatility. The future of pellistor sensors appears bright, with potential growth in areas such as IoT and nanotechnology. These advancements will no doubt enable more accurate and reliable gas detection systems, contributing to safer and more efficient industrial environments.