Moving coil actuators are precise linear motion systems used in medical, aerospace, and manufacturing applications, offering high accuracy and speed.

Moving Coil Actuators: Understanding the Technology and Its Applications

Introduction

Moving coil actuators, also known as voice coil actuators or linear motors, are a type of direct drive linear motion system that offer high precision, fast response times, and long life spans. They are commonly used in a wide range of industries, including medical, aerospace, and manufacturing, due to their versatility and reliability. In this article, we will explore the basic principles of moving coil actuators, their advantages over other types of linear motion systems, and the various applications in which they are employed.

How Moving Coil Actuators Work

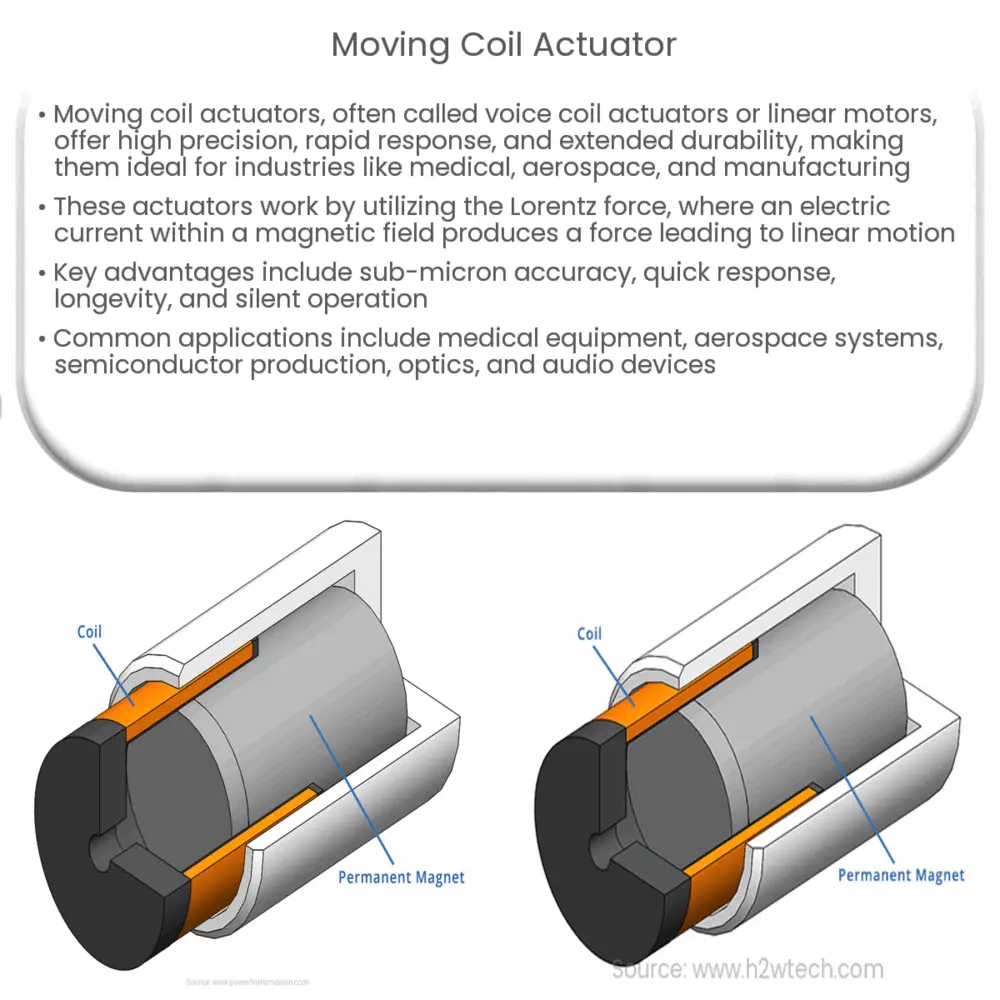

The fundamental principle behind a moving coil actuator is the Lorentz force, which states that when an electric current is passed through a conductor in a magnetic field, a force is generated that is perpendicular to both the current and the magnetic field. In a moving coil actuator, this force is harnessed to create linear motion.

The core components of a moving coil actuator are a stationary permanent magnet assembly and a moving coil. The permanent magnet assembly consists of one or more magnets arranged in a specific configuration to produce a uniform magnetic field, while the moving coil is a wound copper wire that carries the electric current. When current is applied to the coil, it experiences a force due to the interaction with the magnetic field, causing it to move in a linear direction. The magnitude and direction of the force can be controlled by adjusting the current, allowing for precise positioning and movement.

Advantages of Moving Coil Actuators

There are several benefits to using moving coil actuators in linear motion applications. These advantages include:

- High precision and accuracy: Moving coil actuators can achieve sub-micron positioning accuracy, making them ideal for applications that require precise control, such as in medical devices or semiconductor manufacturing.

- Fast response times: Due to their direct drive design, moving coil actuators can respond to input changes quickly, often in just a few milliseconds, allowing for high-speed motion and rapid changes in direction.

- Long life span: With no mechanical contact between the moving coil and the magnetic assembly, moving coil actuators experience minimal wear and tear, leading to a longer operational life compared to other linear motion systems.

- Silent operation: The absence of mechanical friction also results in a quiet operation, making moving coil actuators suitable for noise-sensitive applications such as audio equipment or laboratory instruments.

Applications of Moving Coil Actuators

Moving coil actuators are employed in a diverse range of industries and applications due to their numerous advantages. Some common applications include:

- Medical devices: The high precision and accuracy of moving coil actuators make them well-suited for use in medical equipment, such as surgical robots, drug delivery systems, and diagnostic devices.

- Aerospace and defense: Moving coil actuators are utilized in various aerospace and defense applications, including guidance systems, control surface actuation, and satellite positioning.

- Semiconductor manufacturing: In the production of semiconductor devices, moving coil actuators can be found in wafer positioning systems and pick-and-place machines, where precise positioning is crucial for maintaining high manufacturing yield rates.

- Optics: Moving coil actuators are frequently used in optical systems for applications such as autofocus, image stabilization, and beam steering, where rapid and accurate adjustments are essential.

- Audio equipment: The silent operation of moving coil actuators makes them ideal for use in high-quality audio devices, such as loudspeakers and headphones, where they can accurately reproduce sound with minimal distortion.

Challenges and Limitations

Despite their numerous benefits, moving coil actuators also have some challenges and limitations. Some of these include:

- Force limitations: The force produced by a moving coil actuator is directly proportional to the size of the coil and the strength of the magnetic field. As a result, moving coil actuators may not be suitable for applications that require high force output or that have size constraints.

- Heat generation: The current flowing through the moving coil generates heat, which can affect the performance and life span of the actuator. Proper cooling methods must be employed to manage this heat and maintain optimal performance.

- Cost: Moving coil actuators can be more expensive than other types of linear motion systems due to their complex design and high-quality components. However, the long life span and reduced maintenance requirements of moving coil actuators can offset this initial cost in many applications.

Conclusion

Moving coil actuators provide a highly precise, fast, and reliable method for creating linear motion in various applications. Their numerous advantages make them an attractive choice for industries such as medical, aerospace, manufacturing, and optics. While they may not be suitable for all applications due to force limitations, heat generation, and cost, moving coil actuators remain a valuable and versatile option for many linear motion requirements.