Explore the role, functionality, and benefits of motor temperature sensors, their types, and the future trends in sensor technology.

Understanding Motor Temperature Sensors

Motor temperature sensors, as the name suggests, are devices designed to measure and monitor the temperature of a motor. Their main objective is to protect the motor from damage caused by excessive heat, which can stem from several factors such as overloading, blocked vents, or even failure in the cooling system. To better understand the importance and functionality of these devices, we delve into how they work, their types, and benefits.

Working Principle of Motor Temperature Sensors

Motor temperature sensors operate based on different principles, depending on their type. The most common types are resistance temperature detectors (RTDs), thermocouples, and thermistors. RTDs and thermistors work on the principle that the resistance of certain materials changes with temperature, while thermocouples generate a voltage proportional to the temperature difference between two different metals.

Types of Motor Temperature Sensors

- Resistance Temperature Detectors (RTDs): RTDs are highly accurate and stable sensors, mostly used where precise measurements are required. They function by correlating the resistance of the RTD element with temperature.

- Thermocouples: Thermocouples are cost-effective and durable temperature sensors that can function in a wide range of temperatures. They consist of two different metals joined together at one end. When the junction of the two metals is heated or cooled, it produces a voltage.

- Thermistors: Thermistors are temperature-sensitive resistors, usually made of ceramic or polymer. They offer high sensitivity and accuracy at a relatively low cost. Their resistance changes significantly with temperature, which can be measured and converted to a temperature reading.

Benefits of Using Motor Temperature Sensors

Motor temperature sensors offer a multitude of benefits. Their primary advantage is safeguarding the motor against overheating, which can lead to severe damage. These sensors allow for timely interventions, shutting down the motor or triggering cooling mechanisms when the temperature reaches a critical point. Additionally, motor temperature sensors enable more efficient operation by optimizing motor performance based on temperature data. They can contribute to enhancing the lifespan of the motor, improving reliability, and reducing maintenance costs.

Real-world Applications

Motor temperature sensors find application across various industries, including automotive, industrial, aerospace, and consumer electronics. For instance, in electric vehicles, they help in monitoring and managing the temperature of electric motors to ensure optimal performance and prevent thermal runaway. In industrial applications, they prevent machinery from overheating, thus maintaining productivity and avoiding costly repairs or replacements.

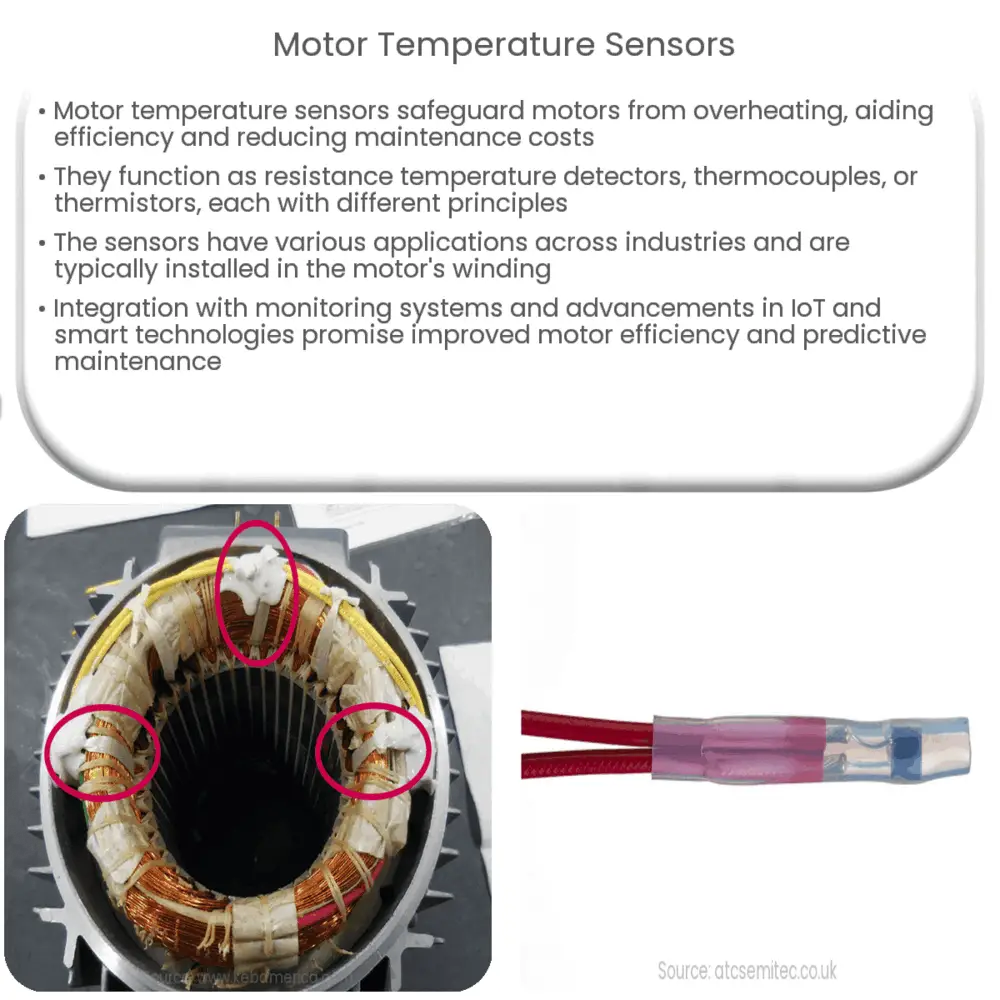

Installation and Placement of Motor Temperature Sensors

Proper installation and placement of motor temperature sensors are crucial to ensure accurate readings and optimal performance. These sensors are typically installed in the winding of the motor, as this area is most susceptible to overheating. In smaller motors, they can be installed in the coil heads or end windings. In larger motors, multiple sensors may be placed at different points to get a comprehensive view of the temperature distribution inside the motor.

Integration with Monitoring Systems

Motor temperature sensors are often integrated with motor monitoring or control systems, allowing for real-time data tracking and automation. When a critical temperature threshold is reached, these systems can trigger an alarm or automatically shut down the motor to prevent damage. Some advanced systems may even regulate the motor speed or initiate cooling mechanisms based on temperature readings, leading to enhanced motor efficiency and longevity.

Future Trends

The future of motor temperature sensors lies in the realms of smart technology and Internet of Things (IoT). With the continuous development of technology, these sensors are expected to become smarter and more integrated. They could potentially provide real-time data to a cloud-based system, facilitating remote monitoring and control. This would not only enhance motor efficiency but also open doors to predictive maintenance, where potential issues could be identified and rectified even before they cause operational disruptions.

Conclusion

In conclusion, motor temperature sensors play a vital role in safeguarding motors from overheating, thereby extending their lifespan and reducing maintenance costs. With a variety of sensor types available, choosing the right one depends on the specific requirements of the motor and its application. Looking forward, the continuous evolution of smart technologies and the IoT is set to further enhance the capabilities of these sensors, making them an integral part of motor design and operation. Ultimately, the effective use of motor temperature sensors will lead to more efficient and reliable motor operations, with substantial benefits for industries and consumers alike.