Explore the intricacies of motor slip rings, their operation, types, applications, maintenance, and future prospects in our detailed guide.

Understanding Motor Slip Rings

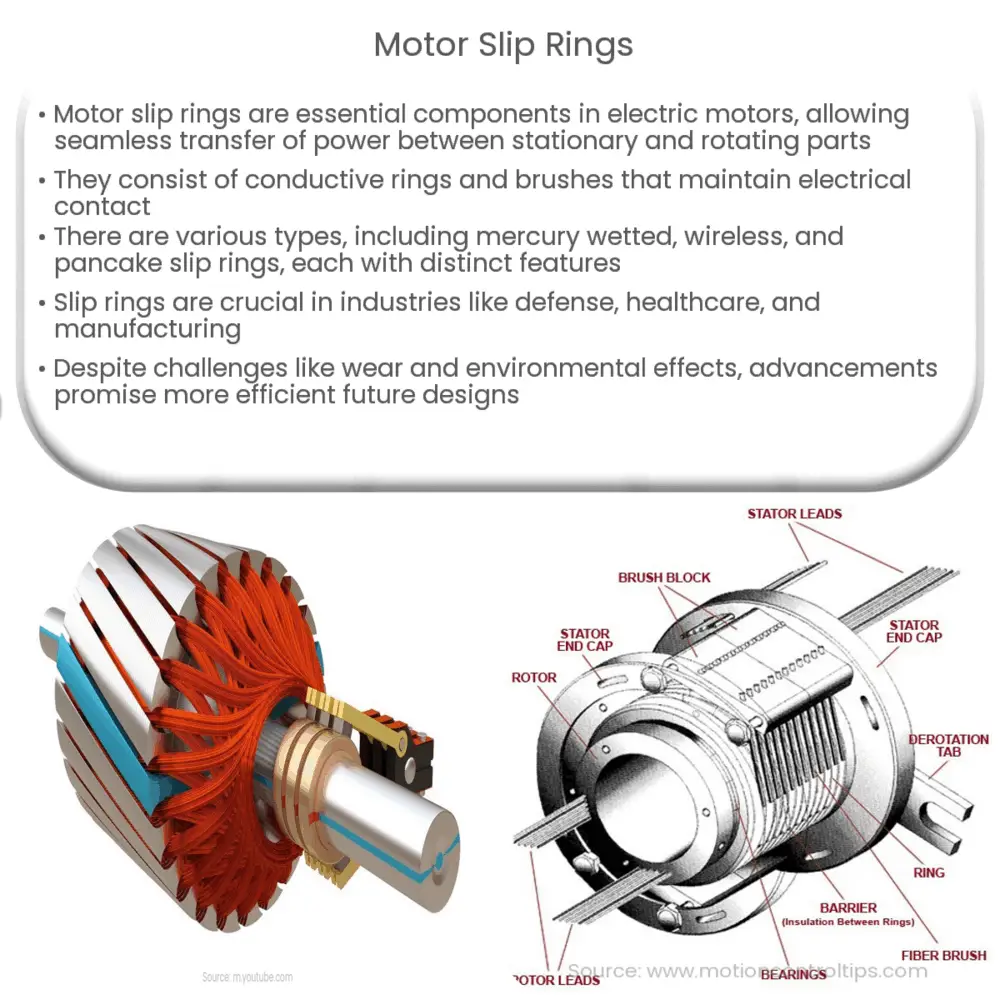

A fundamental aspect of many electric motors, Motor Slip Rings are integral components which serve a pivotal role. They facilitate the transmission of power or signals from a stationary part of the machine to a rotating part. Their primary role is to ensure a seamless transfer of electrical energy without hindering the motor’s motion.

How Motor Slip Rings Operate

Motor slip rings are designed with a set of concentric rings made of conductive material, usually metal, and a set of brushes made of a softer conductive material, such as graphite or copper. The brushes maintain contact with the rings, allowing electrical energy to flow between the stationary and rotating parts of the motor.

Types of Motor Slip Rings

- Mercury Wetted Slip Rings: These slip rings offer low resistance and can conduct high currents. However, their use is limited due to the toxic nature of mercury.

- Wireless Slip Rings: Instead of physical contact, these slip rings use electromagnetic waves to transfer power and signals. This results in less wear and tear and a longer lifespan.

- Pancake Slip Rings: These have a flat, disc-like design. While they offer good performance, they require more space due to their size.

Applications of Motor Slip Rings

- They are widely used in motors for various industrial machinery such as cranes, wind turbines, and packaging machines.

- They can be found in medical equipment such as CT scanners, which require precise and continuous rotation.

- In the field of defense, they are applied in radar antennas and tanks.

The Importance of Motor Slip Rings

Slip rings are paramount to the operation of many types of electric motors. Without them, the efficient and continuous transfer of electrical power from stationary to rotating parts would be a complex and less reliable process. They contribute significantly to the overall performance and efficiency of a motor.[1]

Maintenance of Motor Slip Rings

Despite their robustness and longevity, slip rings require regular maintenance to ensure their efficient functioning. Due to the physical contact between brushes and rings, wear and tear are common occurrences over time. Regular inspection for signs of wear, cleaning to remove accumulated dirt or dust, and periodic replacement of brushes can help maintain the performance of slip rings.[2]

Recent Advances in Motor Slip Ring Technology

Motor slip ring technology has seen significant developments in recent years. Advancements have focused on reducing wear and tear and increasing the lifespan of the rings. There has been a shift towards contactless slip rings that leverage magnetic fields or electromagnetic waves to transfer power and signals. These contactless slip rings offer superior performance, require less maintenance, and have a longer lifespan.[3]

Challenges and Future Prospects

Despite their numerous benefits and advancements, slip rings come with their own set of challenges. For instance, their physical nature may introduce electrical noise, and they can be affected by environmental factors such as temperature or humidity. In addition, there’s an ongoing effort to make slip rings smaller, lighter, and more efficient. Looking forward, we can expect more advancements aimed at overcoming these challenges and further enhancing the capabilities of motor slip rings.[4]

Conclusion

In conclusion, motor slip rings play a critical role in the operation of many electric motors. They enable the seamless transmission of power and signals from stationary to rotating parts, contributing significantly to the efficiency and performance of a motor. Despite the challenges, with advancements in technology and proper maintenance, motor slip rings can offer reliable and effective performance for a broad range of applications. As the field continues to evolve, the future holds great promise for even more refined and efficient motor slip rings.[5]