Explore the importance of motor protection relays, their types, selection criteria, and future trends in motor safety and efficiency.

Understanding Motor Protection Relays

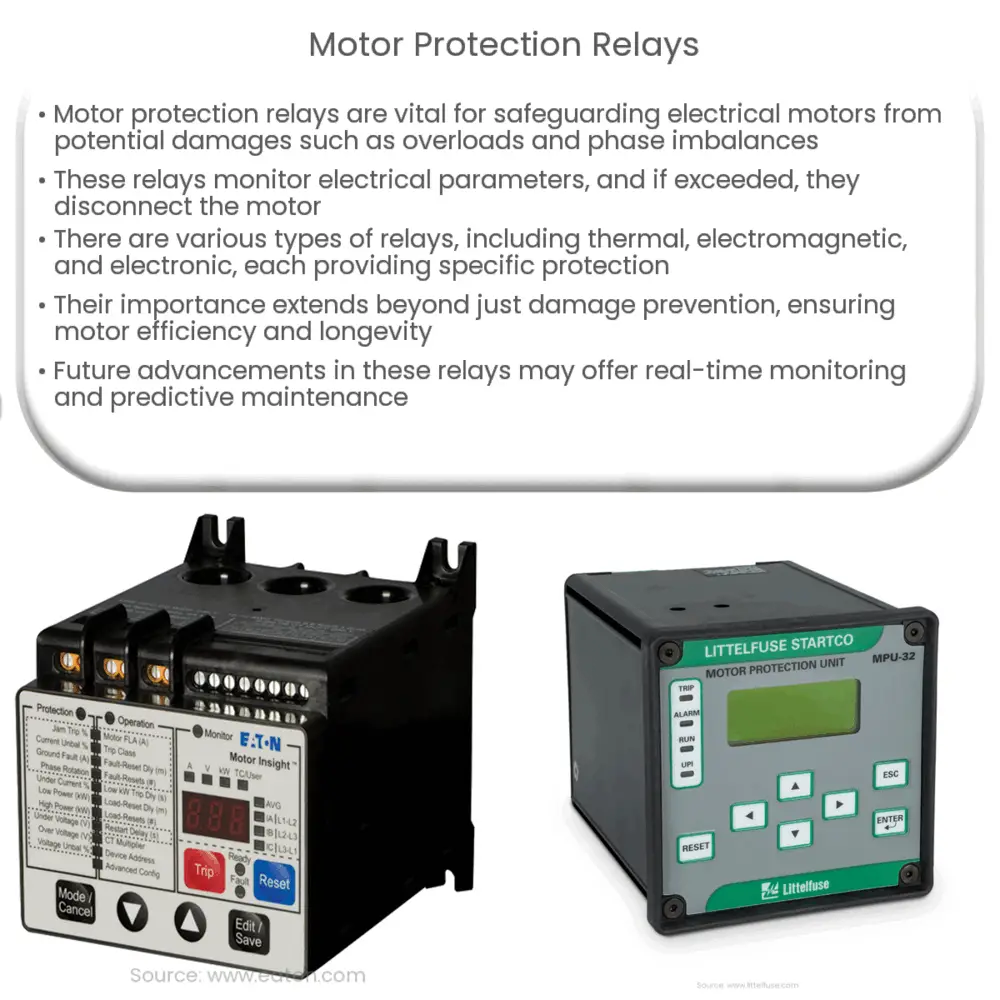

Motor protection relays play a crucial role in safeguarding electrical motors from potential damage that may result from overloads, underloads, phase loss, phase imbalance, or other abnormal conditions. These complex devices are an integral part of modern electrical systems, providing reliable protection and reducing costly downtime.

Operation Principles of Motor Protection Relays

Motor protection relays function on the basis of certain operating principles. Firstly, they monitor electrical parameters such as voltage, current, and sometimes even temperature. When these parameters exceed the preset threshold, the relay operates to protect the motor. This is achieved by sending a trip signal to the circuit breaker, disconnecting the motor from the power source.

Types of Motor Protection Relays

- Thermal Overload Relays: These relays are designed to offer protection against the excessive heat generated by overloads. The relay uses a bi-metallic strip to detect temperature increases. Once the temperature crosses a certain threshold, it trips the circuit.

- Electromagnetic Relays: Working on the principle of electromagnetic induction, these relays are typically used for phase failure and under/over voltage conditions. They act quickly to isolate the motor and protect it.

- Electronic Motor Protection Relays: These are modern, sophisticated relays that can monitor a variety of parameters and offer multi-level protection. With their high sensitivity and accuracy, these relays provide enhanced motor protection.

Importance of Motor Protection Relays

While it’s clear that motor protection relays are essential for preventing motor damage, their significance goes beyond this obvious benefit. They are key to maintaining the efficiency and longevity of electrical motors. By preventing possible electrical faults, these devices minimize operational interruptions, subsequently increasing productivity and reducing maintenance costs.

Choosing the Right Motor Protection Relay

Choosing the appropriate motor protection relay depends on a multitude of factors, such as the type of motor, its application, and the specific risks involved. Therefore, a thorough understanding of the motor’s specifications and operating conditions is paramount.

The right relay can make a significant difference to the motor’s operational lifetime and the overall reliability of the system. Hence, the decision should not be taken lightly. Consultation with professionals and careful analysis of the motor and its environment are key steps in this process.

Key Considerations When Choosing a Motor Protection Relay

- Motor Specifications: The type, size, and operating parameters of the motor should be taken into account. This includes details like horsepower, voltage, full load current, service factor, and more.

- Operational Environment: Factors such as ambient temperature, altitude, humidity, and the likelihood of water or dust ingress should also be considered.

- Application: The specific use of the motor, such as continuous operation, starting/stopping frequency, load characteristics, and whether it operates individually or as part of a group, all play a significant role in the selection of the appropriate relay.

Relay Settings and Commissioning

Once the suitable motor protection relay has been selected, it is important to correctly set the relay parameters to match the motor characteristics and operating conditions. Incorrect settings can result in either insufficient protection or unnecessary tripping.

Commissioning the relay involves testing it in a real-world scenario to ensure it functions as expected. This is a critical step to verify that the relay is ready to protect the motor under all potential fault conditions.

The Future of Motor Protection Relays

The field of motor protection continues to evolve with advancements in technology. Future trends include increased integration with automation systems, real-time monitoring, predictive maintenance, and remote control capabilities. Smart relays will play a key role in the era of Industry 4.0, providing not only protection but also valuable data for improving operational efficiency.

Conclusion

In conclusion, motor protection relays are indispensable tools for safeguarding electrical motors from potentially damaging conditions. From thermal overload relays to more sophisticated electronic relays, these devices ensure the longevity and efficiency of motors, thus enhancing overall system reliability. Selecting the right relay, setting it correctly, and ensuring proper commissioning are key aspects of effective motor protection. As technology advances, motor protection relays are likely to become even more integral to the safe and efficient operation of industrial systems. Embracing these advancements can lead to improved performance, lower maintenance costs, and greater operational efficiency.