Explore the importance of motor noise suppression filters in electronic systems, their types, selection criteria, and future developments.

Understanding Motor Noise Suppression Filters

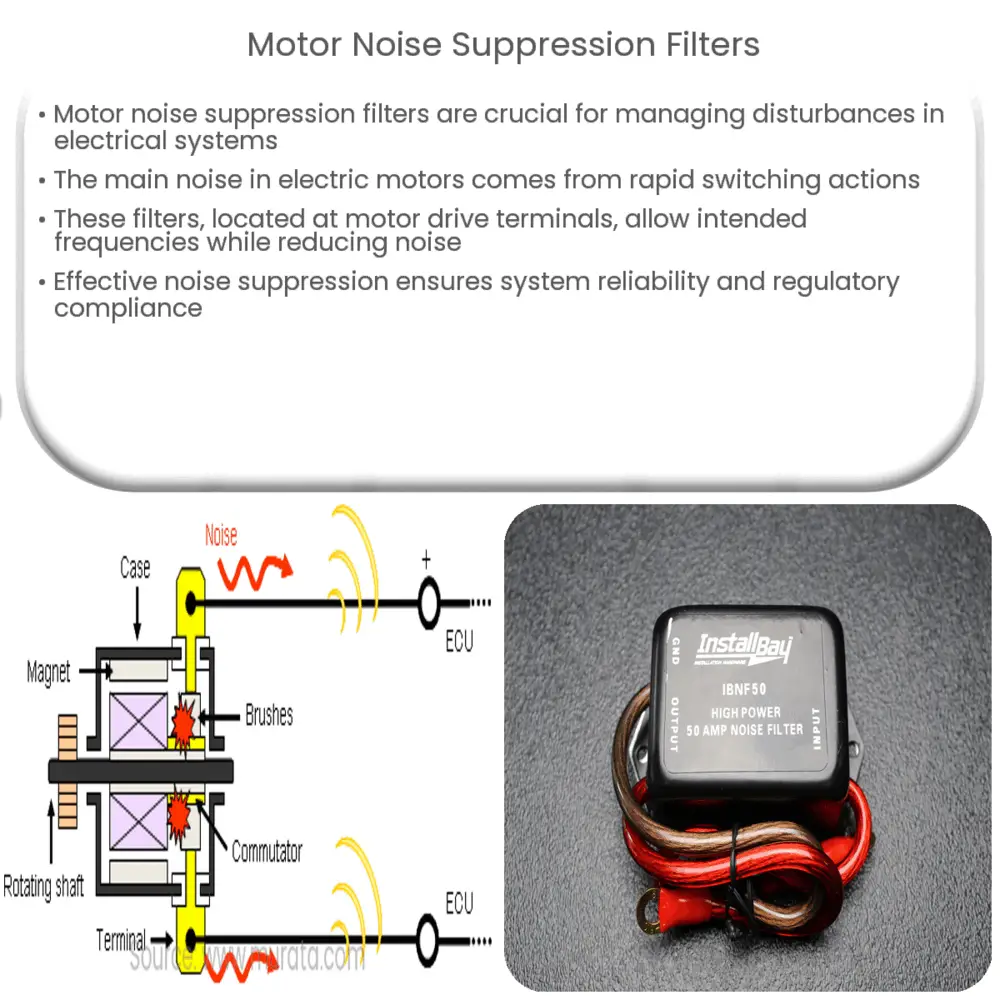

Motor noise suppression filters, also known as EMI (Electromagnetic Interference) filters or RF (Radio Frequency) filters, play a critical role in modern electrical and electronic systems. These filters are crucial in suppressing the noise produced by electric motors, which if not checked, can cause significant disturbances in the device operation and other nearby electronics.

The Source of Motor Noise

The primary source of noise in electric motors is the rapid switching actions in the motor controllers, like in variable frequency drives (VFDs). This rapid switching, while highly efficient, can generate high-frequency electromagnetic noise known as EMI. This EMI, if not effectively managed, can propagate along power lines and radiate into the surrounding environment, causing potential disturbances.

How Motor Noise Suppression Filters Work

Motor noise suppression filters function by attenuating the strength of the unwanted noise signals. These filters are generally located at the input or output terminals of the motor drive and are designed to allow the intended frequencies to pass while significantly reducing the noise.

Types of Motor Noise Suppression Filters

- Common Mode Filters: These filters suppress the common mode noise signals, which are the same on all lines. Common mode filters are often used for noise suppression in data lines.

- Differential Mode Filters: These filters attenuate the noise that is different across lines, which is often the main noise type in power lines.

- Combined Filters: A combined common and differential mode filter can provide comprehensive noise suppression.

The Importance of Motor Noise Suppression Filters

Without effective motor noise suppression, the performance and reliability of both the motor and the entire system can be compromised. In fact, the lack of appropriate EMI filtering can even lead to non-compliance with various regulatory standards, such as those set out by the FCC in the United States or the CISPR internationally.

Furthermore, excessive motor noise can lead to poor power quality, which can have a cascading effect on system performance, potentially causing malfunctions or even system failure. Therefore, the importance of motor noise suppression filters cannot be overstated.

Choosing the Right Motor Noise Suppression Filter

When selecting a motor noise suppression filter, several key factors need to be considered:

- Type of noise: The filter must be chosen based on whether the noise is common mode or differential mode. This is critical because different filter designs are more effective at suppressing certain types of noise.

- Operating conditions: The filter’s ability to withstand the operating conditions, such as temperature range and humidity, is another crucial factor.

- Regulatory requirements: Depending on the application, there may be specific regulatory requirements to adhere to, such as FCC or CISPR standards.

- Cost: While cost should not compromise performance and compliance, it is an important consideration when selecting a motor noise suppression filter.

Installation and Maintenance

Proper installation and maintenance are also vital to the effective operation of motor noise suppression filters. A poorly installed filter may not perform as expected, and if not regularly checked and maintained, the filter’s efficiency can diminish over time.

Maintenance should include periodic inspection of the filter, checking for signs of wear and tear, and replacement if necessary. In addition, any changes in the operating environment, such as an increase in noise levels, should be investigated and addressed promptly.

Future Developments

As technology continues to advance, we can expect to see further developments in motor noise suppression filters. These could include more efficient designs, better materials for increased durability and performance, and perhaps even smart filters that can adapt to changing noise conditions. The increasing reliance on electronic and electrical systems in a wide range of applications underscores the ongoing need for effective noise suppression strategies.

Conclusion

In conclusion, motor noise suppression filters are essential components in the efficient operation of electrical and electronic systems. They help mitigate the negative effects of electromagnetic interference, ensuring that motors and other devices function optimally. Selecting the right filter requires understanding the type of noise, the operating conditions, and any relevant regulatory requirements. Moreover, proper installation and regular maintenance are necessary for the filter’s effective operation. As technology evolves, we anticipate that motor noise suppression filters will continue to be a crucial part of electrical and electronic system design, safeguarding equipment functionality and contributing to regulatory compliance.