Explore the importance of motor laminations in electric motors, their types, manufacturing process, material selection, and future developments.

Understanding Motor Laminations

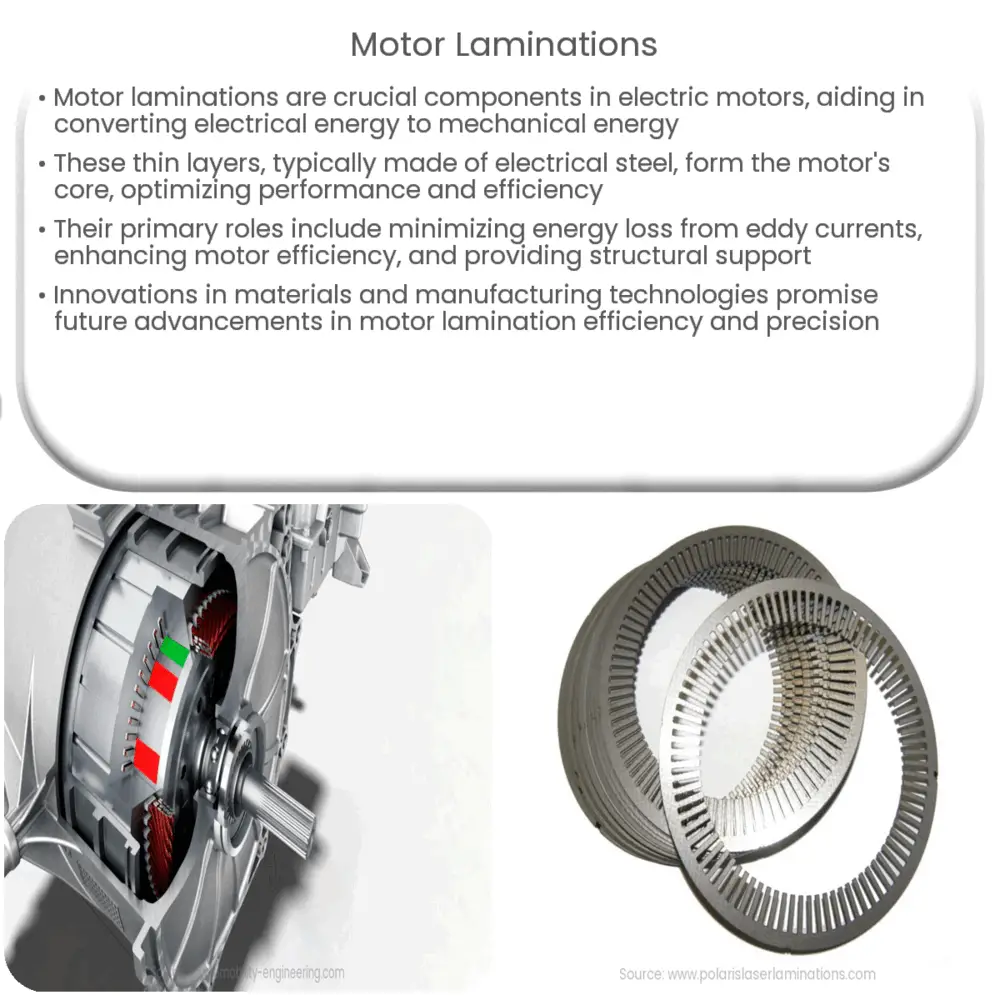

The heart of an electric motor, responsible for its functioning, comprises various key elements, and among these, motor laminations hold a significant position. Motor laminations are essential components in any electric motor, contributing to the conversion of electrical energy into mechanical energy.

Before diving into the intricacies of motor laminations, it is crucial to underscore the vital role of electric motors in today’s technological era. From household appliances such as refrigerators and washing machines to electric vehicles and industrial machinery, electric motors play a pivotal role in powering our daily lives. With such broad applications, understanding the operation and components of an electric motor, especially the motor laminations, is necessary.

Motor Laminations: A Closer Look

Motor laminations are thin layers of a special type of metal alloy, usually electrical steel, that are stacked together to form the core of an electric motor. These laminations are designed to minimize energy loss, optimize the motor’s performance, and improve the efficiency of the electrical-to-mechanical energy conversion.

Role of Motor Laminations

-

Minimizing Eddy Currents: Eddy currents are circulating currents induced within the motor by the alternating magnetic field. They can cause significant energy loss and overheating. By stacking thin laminations with an insulating material in between, the flow of eddy currents is greatly reduced.

-

Improving Efficiency: The reduction in energy loss, thanks to the control of eddy currents, leads to improved motor efficiency. With less wasted energy, the motor can deliver greater output for a given electrical input.

-

Supporting Motor Structure: Beyond efficiency, the laminations also provide structural support to the motor. They form the stator (stationary part) and rotor (rotating part) of the motor, thus playing a critical role in the motor’s mechanical function.

Types of Motor Laminations

There are several types of motor laminations, each designed for specific motor requirements. These include:

-

Toroidal Laminations: These are used in motors where the coil is wound around the entire core.

-

Interlocked Laminations: These laminations are designed with a specific pattern to ensure they fit together perfectly, optimizing energy transfer and efficiency.

-

Segmented Laminations: They are used in motors where the stator core is made from segments rather than a single piece, offering flexibility in design and construction.

This part of the article provides an initial understanding of the concept and role of motor laminations. We will delve further into this topic, focusing on the manufacturing process, material selection, and the future of motor laminations in the upcoming sections.

Manufacturing Process of Motor Laminations

The manufacturing of motor laminations involves a number of steps:

-

Material Selection: The first step involves selecting the right material, usually an electrical steel, for the lamination. This is crucial as the material’s properties directly influence the motor’s efficiency and performance.

-

Sheet Preparation: The selected material is then rolled into thin sheets, which are coated with an insulating material to mitigate the effects of eddy currents.

-

Cutting and Stamping: The insulated sheets are cut and stamped into the required shape and size. Advanced laser cutting and punching technologies are used for this purpose to ensure precision and consistency.

-

Stacking and Assembly: The cut laminations are then stacked together and assembled to form the motor core.

Choosing the Right Material for Motor Laminations

Material selection for motor laminations is a critical aspect that directly affects motor efficiency and performance. Electrical steel, a specialized steel tailored to produce certain magnetic properties, is the most commonly used material. It exhibits low coercivity, meaning the material’s magnetism can be easily reversed, making it an ideal choice for the alternating magnetic fields within motors.

Grain-oriented electrical steel is preferred for high-efficiency motors. Its magnetic properties are optimized in one direction, reducing energy losses and enhancing the motor’s overall efficiency.

The Future of Motor Laminations

With technological advancements, the field of motor laminations is expected to see significant developments. Innovations in materials, such as nanocrystalline materials, offer promising potential for higher efficiency and performance in future electric motors. Additionally, advancements in manufacturing technologies, including 3D printing and laser-cutting, promise more precise and efficient production of motor laminations.

Conclusion

In conclusion, motor laminations play an essential role in the functioning of electric motors. They help in minimizing energy loss, improving efficiency, and providing structural support to the motor. From material selection to the manufacturing process, every aspect of motor lamination production requires precision and understanding of the motor’s functioning. With continual advancements in technology, we can anticipate a future where motor laminations contribute to even more efficient and high-performing electric motors, further revolutionizing our technological landscape.