A MEMS gyroscope is a miniaturized sensor that measures angular velocity, crucial in applications like navigation, gaming, and vehicle safety systems.

Understanding MEMS Gyroscopes: Principles and Applications

Introduction

The advancement of technology has paved the way for smaller, more efficient, and cost-effective devices. One such technology that has revolutionized various industries is the Micro-Electro-Mechanical Systems (MEMS) gyroscope. This article delves into the principles of MEMS gyroscopes, their unique features, and the wide range of applications they serve.

What is a MEMS Gyroscope?

A MEMS gyroscope is a miniaturized device used to measure angular velocity or rotation rate. It is a type of inertial sensor that can detect changes in orientation and is essential in various applications such as navigation systems, gaming consoles, and unmanned aerial vehicles (UAVs). The term “gyroscope” is derived from Greek words “gyros,” meaning “rotation,” and “skopos,” meaning “observer.

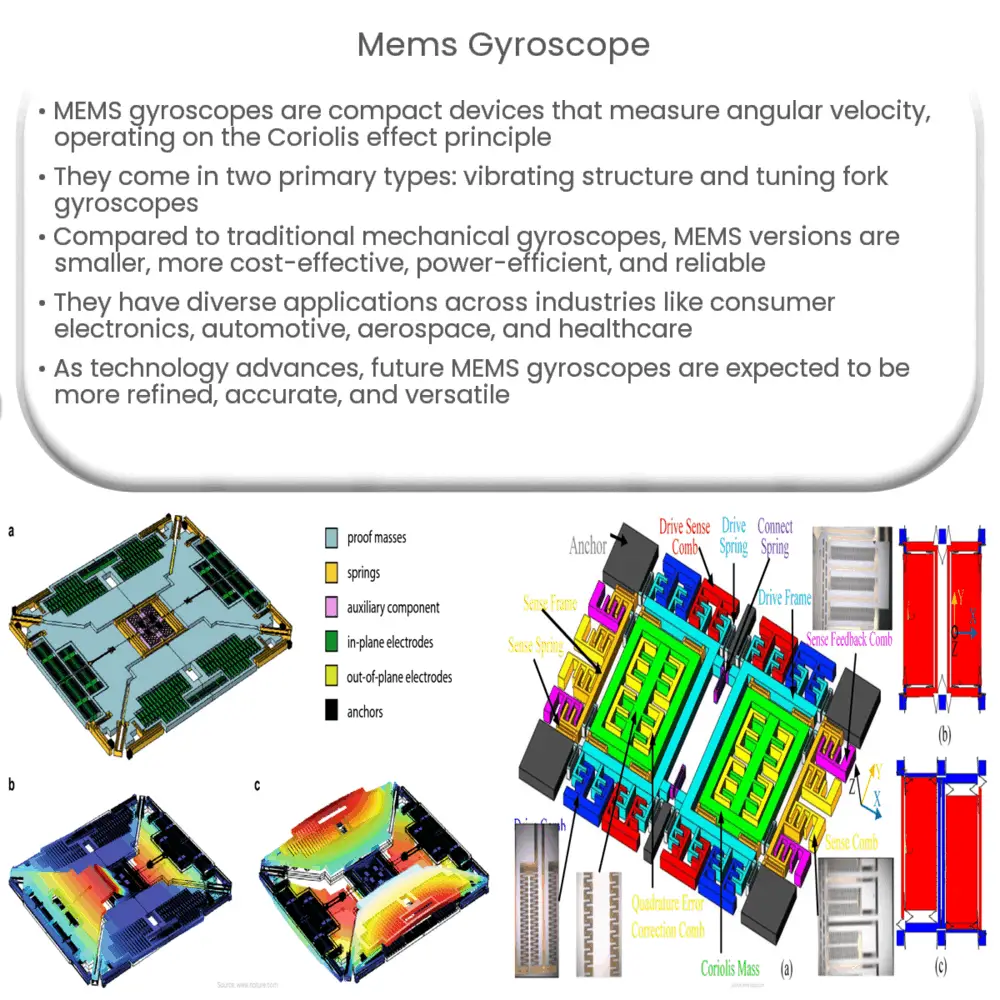

MEMS gyroscopes operate on the principle of the Coriolis effect, which causes a force to act on a mass moving in a rotating system. The resulting force is perpendicular to both the mass’s velocity and the rotation axis. The MEMS gyroscope measures the Coriolis effect to determine the angular velocity or rotation rate of the system.

Types of MEMS Gyroscopes

There are two primary types of MEMS gyroscopes: vibrating structure gyroscopes and tuning fork gyroscopes. Each type has its unique features and applications:

Vibrating Structure Gyroscopes

Vibrating structure gyroscopes use a vibrating mass to sense rotation. They typically have a resonant structure that can be driven into oscillation, such as a vibrating wheel or a tuning fork. When the structure rotates, the Coriolis force causes a secondary oscillation, which is measured to determine the angular velocity. Vibrating structure gyroscopes are used in various applications, including automotive safety systems and consumer electronics.

Tuning Fork Gyroscopes

Tuning fork gyroscopes use a pair of vibrating masses, or “tines,” that are driven into oscillation at their resonant frequency. The Coriolis force acts on the tines when the device rotates, causing a secondary oscillation. This secondary oscillation is measured to determine the angular velocity. Tuning fork gyroscopes offer higher sensitivity and better temperature stability than vibrating structure gyroscopes, making them suitable for high-precision applications such as aerospace and industrial systems.

Advantages of MEMS Gyroscopes

MEMS gyroscopes offer several advantages over traditional mechanical gyroscopes, including:

- Size: MEMS gyroscopes are significantly smaller and lighter than their mechanical counterparts, making them ideal for applications where size and weight constraints are critical.

- Cost: Due to their microfabrication process, MEMS gyroscopes are more cost-effective to produce than traditional gyroscopes, making them accessible to a broader range of industries and applications.

- Power consumption: MEMS gyroscopes consume less power than mechanical gyroscopes, which is crucial for battery-powered devices and energy-efficient systems.

- Reliability: The solid-state construction of MEMS gyroscopes offers higher reliability and longer operational lifetimes than mechanical gyroscopes, which are prone to wear and tear.

Applications of MEMS Gyroscopes

MEMS gyroscopes have a wide range of applications across various industries, some of which include:

Consumer Electronics

MEMS gyroscopes are widely used in smartphones, tablets, and gaming consoles to detect device orientation, enabling features such as screen rotation and motion-based gaming. They also contribute to image stabilization in cameras and camcorders, improving the quality of photos and videos.

Automotive Industry

In the automotive sector, MEMS gyroscopes play a critical role in vehicle safety systems such as electronic stability control (ESC) and anti-lock braking systems (ABS). These systems rely on the accurate measurement of vehicle dynamics to maintain stability and prevent accidents.

Aerospace and Defense

High-precision MEMS gyroscopes are essential in the aerospace and defense industries, where they are used for navigation and guidance systems in aircraft, satellites, and unmanned aerial vehicles (UAVs). They provide accurate and reliable information about an object’s orientation, allowing for precise control and maneuverability.

Industrial Automation

MEMS gyroscopes are used in various industrial applications, including robotics and automation systems, where they help maintain stability and ensure accurate positioning. They are also used in surveying equipment and heavy machinery to monitor and control motion and orientation.

Healthcare and Medical Devices

In the healthcare sector, MEMS gyroscopes have found applications in medical devices such as surgical navigation systems and rehabilitation equipment. They help track and monitor patient movement, enabling more accurate diagnostics and treatments.

Future Developments and Challenges

As technology continues to advance, MEMS gyroscopes are expected to become even smaller, more accurate, and more energy-efficient. Research is ongoing to develop new materials and fabrication techniques that will further enhance the performance of these devices.

Despite their numerous advantages, MEMS gyroscopes still face challenges such as sensitivity to environmental factors like temperature, humidity, and vibration. Efforts are being made to improve their robustness and reliability under these conditions. Additionally, researchers are working on the integration of MEMS gyroscopes with other sensors, such as accelerometers and magnetometers, to create more advanced and versatile inertial measurement units (IMUs).

Conclusion

MEMS gyroscopes have revolutionized various industries by providing a compact, cost-effective, and reliable solution for measuring angular velocity and rotation rate. Their applications span across consumer electronics, automotive, aerospace, industrial automation, and healthcare sectors. As research and development continue, we can expect even more advanced MEMS gyroscopes with enhanced performance and capabilities, further expanding their range of applications and driving innovation across industries.