Explore the working, benefits, applications, and future trends of Magnetostrictive Level Sensors in various industries.

Magnetostrictive Level Sensor: An Introduction

In the diverse landscape of industrial sensors, the Magnetostrictive Level Sensor holds a unique and prominent position. The sensor is widely used for measuring the level of fluids in a variety of industrial applications, including petrochemical storage, hydraulic systems, and food and beverage production.

Understanding the Magnetostrictive Principle

At the heart of the Magnetostrictive Level Sensor lies the principle of magnetostriction. Magnetostriction refers to the change in the dimensions of a ferromagnetic material when it is magnetically energized. In simpler terms, certain materials have the ability to change their shape or dimensions when they are subjected to a magnetic field.

Working Mechanism

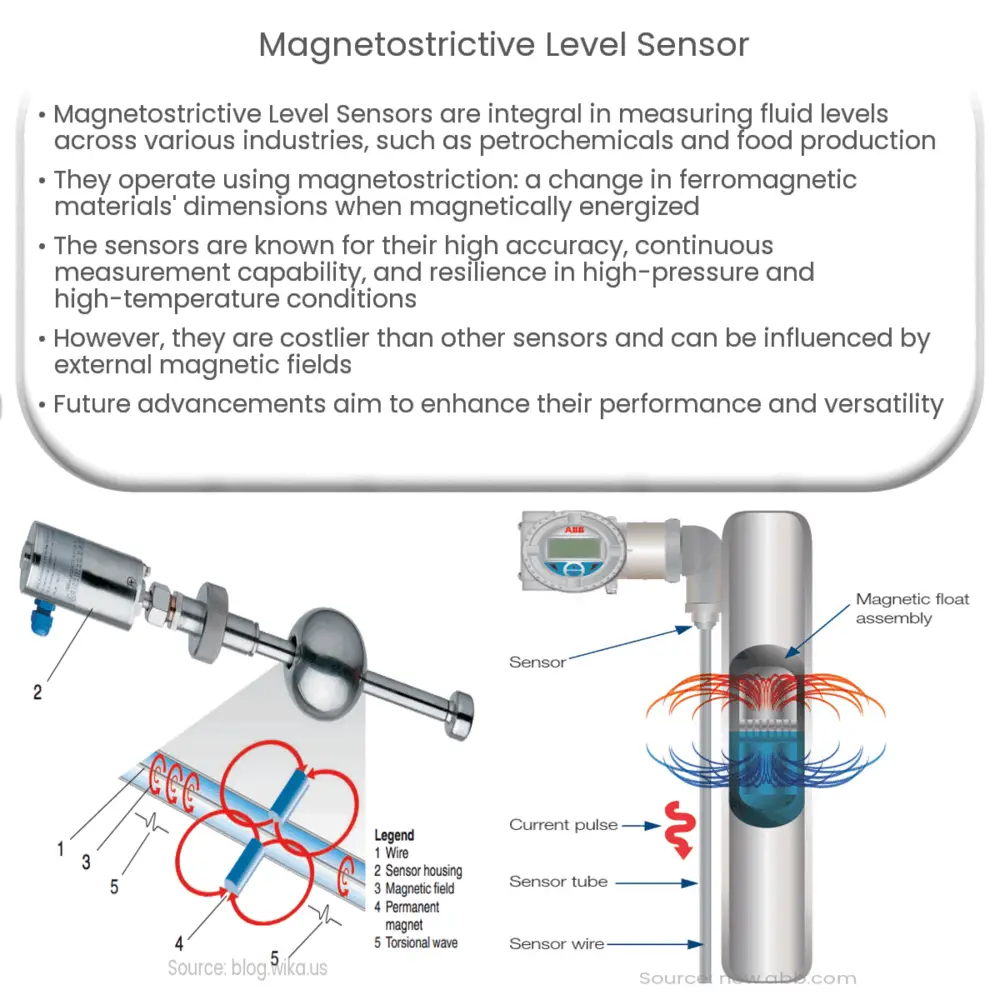

The primary components of a Magnetostrictive Level Sensor include a magnetic float, a waveguide, a position magnet, and an electronics assembly. This sensor operates based on the generation of a torsional stress wave in a specially designed magnetostrictive waveguide.

- Waveguide: It is a thin wire usually made of a ferromagnetic alloy. It runs the entire length of the probe.

- Magnetic Float: It moves up and down with the level of the liquid. The float contains a ring magnet which creates a magnetic field around it.

- Position Magnet: It is usually fixed to the object whose position needs to be measured. It creates a magnetic field when it comes into contact with the waveguide.

- Electronics Assembly: It sends an electrical pulse down the waveguide, which in turn interacts with the magnetic field from the float to generate a torsional stress wave.

The time taken by the torsional wave to return to the electronics assembly is directly proportional to the position of the float along the waveguide. This time delay is then translated into a level measurement.

Unique Benefits

Magnetostrictive Level Sensors offer several key advantages over other level measurement technologies. They are highly accurate, typically offering a precision of 0.01% of full scale. They are also capable of providing continuous level measurement and can handle high pressure and high temperature environments. Furthermore, they are not affected by changes in the properties of the medium, such as density, conductivity, or dielectric constant.

Application Areas of Magnetostrictive Level Sensors

Magnetostrictive Level Sensors have a broad range of applications across various industries. They are commonly used in industries where precision and reliability are of utmost importance.

- Petrochemical Industry: These sensors are extensively used in the petrochemical industry for level measurement of various fuels and oils in storage tanks and reservoirs.

- Food and Beverage Industry: They help in measuring the level of various liquids such as juices, milk, and other beverages in production lines and storage tanks.

- Pharmaceutical Industry: For maintaining stringent hygiene standards, these sensors are used to measure levels of various pharmaceutical liquids in sterile conditions.

- Water Treatment Plants: They are used for level measurement in water storage tanks and reservoirs.

Challenges and Limitations

Despite the numerous advantages, Magnetostrictive Level Sensors are not without their challenges. They are typically more expensive than other level sensing technologies, which may deter some industries from adopting them. Furthermore, they may be influenced by external magnetic fields, which can potentially impact their accuracy. Lastly, while these sensors are capable of withstanding high temperatures and pressures, they have a limit to the level of harsh conditions they can endure.

Looking Ahead

With the ever-evolving advancements in sensor technology, Magnetostrictive Level Sensors are expected to see further improvements in their performance and versatility. Researchers are continually seeking ways to overcome existing limitations and expand the potential applications of these sensors. Enhancements in materials and electronics may lead to increased accuracy, wider operating ranges, and even more robust performance in challenging environments.

Conclusion

In conclusion, Magnetostrictive Level Sensors stand out in the field of level measurement technologies due to their high accuracy, reliability, and suitability for a wide range of applications. Despite certain challenges, their benefits often outweigh the limitations, making them an ideal choice for many industries. As research and technological advancements continue, we can expect these sensors to play an even more significant role in the industrial world.