Dive into the world of magnetic speed sensors: understand their operation, types, applications, benefits, limitations, and future trends.

Understanding Magnetic Speed Sensors

Magnetic speed sensors are highly utilized components in various industrial applications. Their primary function is to monitor rotational speed, often used in the automotive industry, but also applied to a broad range of other sectors. They work by detecting changes in magnetic fields. In this article, we will delve deeper into their principle of operation, their types, and key applications.

How Magnetic Speed Sensors Operate

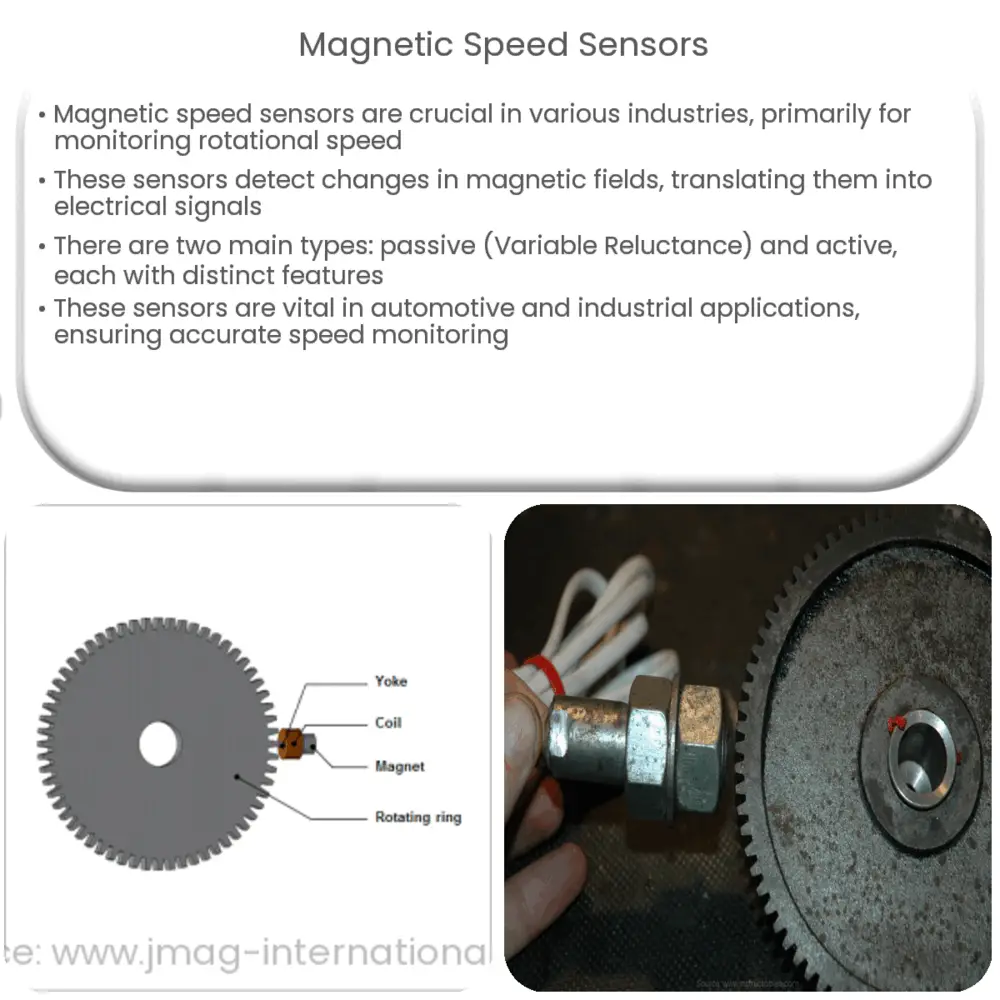

At the heart of a magnetic speed sensor is a magnetic field. This field interacts with a magnetically permeable target, often a gear tooth or a rotating disk. As the target moves through the sensor’s magnetic field, it causes changes in the magnetic field’s distribution. These changes are detected and translated into electrical signals, proportional to the rotational speed of the target.

Types of Magnetic Speed Sensors

There are two principal types of magnetic speed sensors: active and passive. Each has its unique set of attributes and suitable applications.

- Passive Magnetic Speed Sensors: Also known as Variable Reluctance (VR) sensors, these devices operate without the need for an external power source. A VR sensor is essentially a coil of wire wound around a magnetic core, and it generates an output signal through electromagnetic induction.

- Active Magnetic Speed Sensors: Unlike VR sensors, active magnetic speed sensors require an external power source to operate. They employ a permanent magnet and a coil or a Hall-effect or magneto-resistive element to generate a continuous voltage output proportional to the target’s speed.

Applications of Magnetic Speed Sensors

Magnetic speed sensors are integral to many modern systems. From vehicle systems to industrial equipment, they are a key part of ensuring accurate speed monitoring and control.

- Automotive Applications: In vehicles, these sensors are often used in anti-lock braking systems (ABS), engine control units (ECU), and automatic transmissions to monitor rotational speed of various parts.

- Industrial Applications: In industries, they are commonly used in motor speed control, flow rate sensing for liquids or gases, and monitoring rotational speed in machinery such as turbines and pumps.

To fully grasp the potential of these devices, we will delve further into their significant benefits, limitations, and the latest trends in magnetic speed sensor technology in the following section.

Benefits and Limitations of Magnetic Speed Sensors

Like any other technology, magnetic speed sensors come with their own set of advantages and disadvantages, which make them suitable for specific applications.

- Benefits: Magnetic speed sensors offer numerous benefits. They are highly reliable and durable, with the ability to function accurately in challenging conditions such as high temperatures, vibration, or dirty environments. They also have a wide operating range, providing accurate measurements at very high or low speeds.

- Limitations: On the downside, magnetic speed sensors may be affected by external magnetic fields, and their performance can diminish over time due to wear and tear. They may also be sensitive to target material and distance.

Future Trends in Magnetic Speed Sensor Technology

As we look towards the future, there are several promising developments in magnetic speed sensor technology. With the growth of the Internet of Things (IoT) and Industry 4.0, there is an increasing demand for sensors that can deliver high-precision measurements in real-time. This trend is driving the development of smart magnetic speed sensors, which can process data on the sensor itself, reducing the need for additional processing power elsewhere in the system.

Another noteworthy trend is the advent of miniaturized magnetic speed sensors. As devices become smaller and more integrated, there is a growing need for sensors that can fit into compact spaces without compromising on performance. These advancements in sensor miniaturization are expected to open up new application areas for magnetic speed sensors.

Conclusion

In conclusion, magnetic speed sensors are indispensable tools in a variety of applications, from automotive systems to industrial equipment. They offer several benefits, including high reliability, durability, and wide operating ranges. Although they have certain limitations, ongoing advancements in sensor technology are continually enhancing their performance and application potential. With the growth of IoT and Industry 4.0, the role of magnetic speed sensors is set to become even more significant, opening up new avenues for innovation and application.