Explore the world of magnetic encoder systems, their types, working principle, applications, advantages, challenges, and future prospects in our detailed guide.

Magnetic Encoder Systems: An Overview

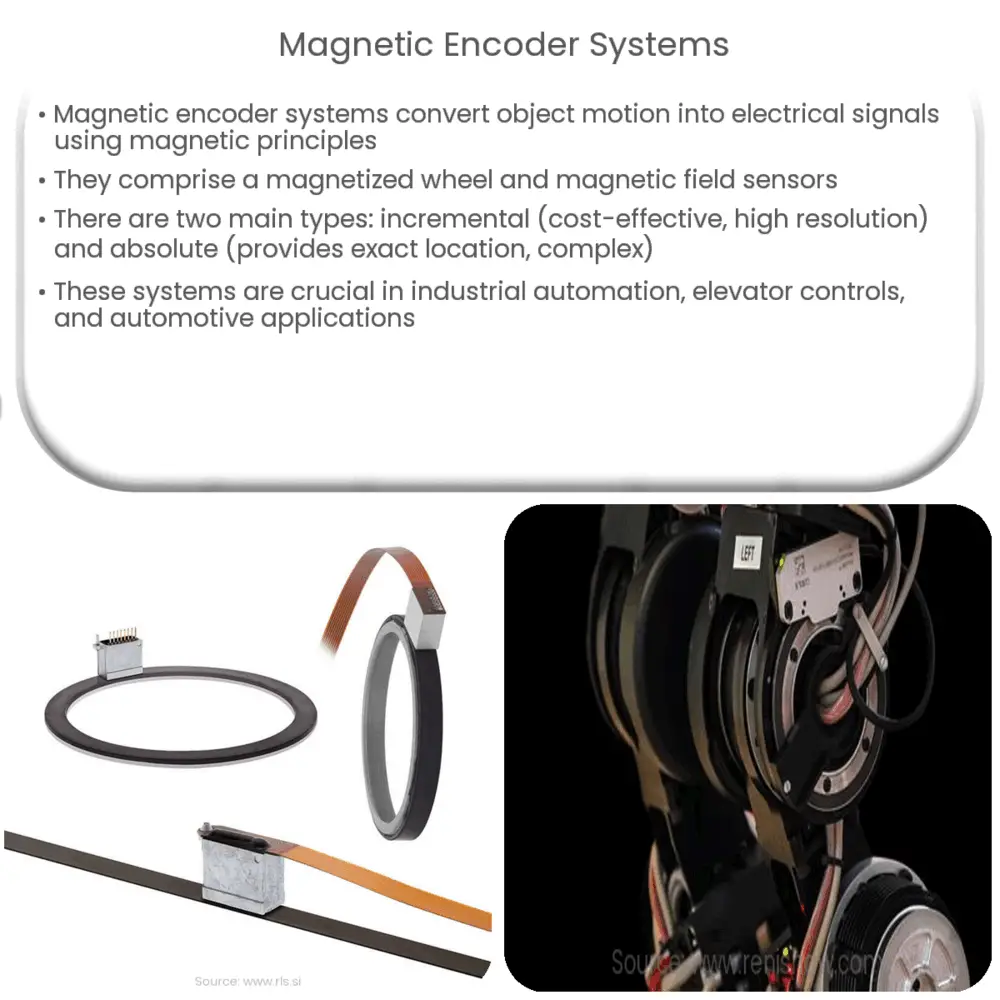

Magnetic encoder systems are vital components in a variety of applications, providing precise measurements of position and velocity. They function by converting the motion of an object into digital or analog electrical signals, a process that hinges on the magnetic phenomenon.

The magnetic encoder system primarily comprises two essential components: a magnetized wheel (rotor) and a set of magnetic field sensors. The wheel rotates with the object whose motion is being monitored, while the sensors detect alterations in the magnetic field created by this rotation.

Types of Magnetic Encoder Systems

There are two primary types of magnetic encoders: incremental and absolute. Both have unique benefits and are better suited for certain applications.

- Incremental Encoders: These provide relative position information, where the output is the change in position since the last measurement. They are cost-effective and provide high resolution, making them ideal for applications where velocity is the primary concern.

- Absolute Encoders: These encode a unique output for each position, providing precise information about the exact location of the monitored object, regardless of movement. They are typically more complex and expensive but necessary for applications requiring detailed positional data.

Applications of Magnetic Encoder Systems

Magnetic encoder systems find their utility in numerous areas. Let’s explore a few significant applications:

- Industrial Automation1: With their ability to provide precise positional and velocity data, magnetic encoders are indispensable in modern automation technology. They help in ensuring accuracy and reliability in the control of robotic arms, CNC machines, and conveyor belts.

- Elevator Control Systems2: For smooth and safe operations, elevators require precise control over the car’s movement. Magnetic encoders play a crucial role here, providing feedback on speed and position, thereby ensuring the car stops accurately at each floor.

- Automotive Applications3: In vehicles, magnetic encoders are employed for a wide range of purposes. They help monitor wheel speed for ABS systems, control electric windows and mirrors, and manage engine and transmission systems.

This is just the tip of the iceberg when it comes to the capabilities and applications of magnetic encoder systems. As we delve deeper into the topic, we’ll gain insights into the working principles of these systems, their key benefits, challenges, and the future possibilities they hold.

How Magnetic Encoder Systems Work

Magnetic encoders operate on the principles of magnetism. In a typical setup, a magnetic encoder has a rotating magnet or magnetic strip and a sensor that reads the magnetic field. As the magnet rotates or the strip moves, the magnetic field changes accordingly. The sensor reads these changes and converts them into digital or analog signals that can be processed and used for various applications.

Advantages of Magnetic Encoder Systems

- Robustness1: Unlike optical encoders that can be sensitive to dust, dirt, and other environmental factors, magnetic encoders can withstand harsh environments. This makes them perfect for use in industrial settings.

- Cost-effectiveness2: Magnetic encoders are generally more affordable than other types of encoders, such as optical encoders. This makes them a cost-effective solution for many applications.

- Flexibility3: The design of magnetic encoders allows for more flexibility in mounting and alignment than other types of encoders. This makes them easier to integrate into existing systems.

Challenges and Future Prospects

Despite their advantages, magnetic encoders also face challenges. For instance, they can be susceptible to interference from other magnetic fields. This can result in inaccuracies in the encoder’s output. However, advancements in technology are continually improving the accuracy and reliability of magnetic encoders.

Looking ahead, magnetic encoder technology holds exciting possibilities. With continued advancements in miniaturization and materials science, we can anticipate magnetic encoders becoming even smaller, more efficient, and capable of handling even more complex tasks. The fusion of magnetic encoder systems with artificial intelligence and machine learning could unlock new capabilities, opening up untold possibilities in robotics, automation, and beyond.

Conclusion

In conclusion, magnetic encoder systems are a pivotal part of modern technology, providing crucial data for precise control in numerous applications, from industrial automation to automotive applications. Despite certain challenges, their inherent advantages of robustness, cost-effectiveness, and flexibility make them an attractive choice for many applications. With continued technological advancements, the future of magnetic encoder systems promises even greater possibilities, making them an essential area to watch for anyone interested in the fields of engineering and technology.