Explore the fundamentals of magnetic couplings, their types, applications, advantages, challenges, and future trends in this comprehensive guide.

Introduction to Magnetic Couplings

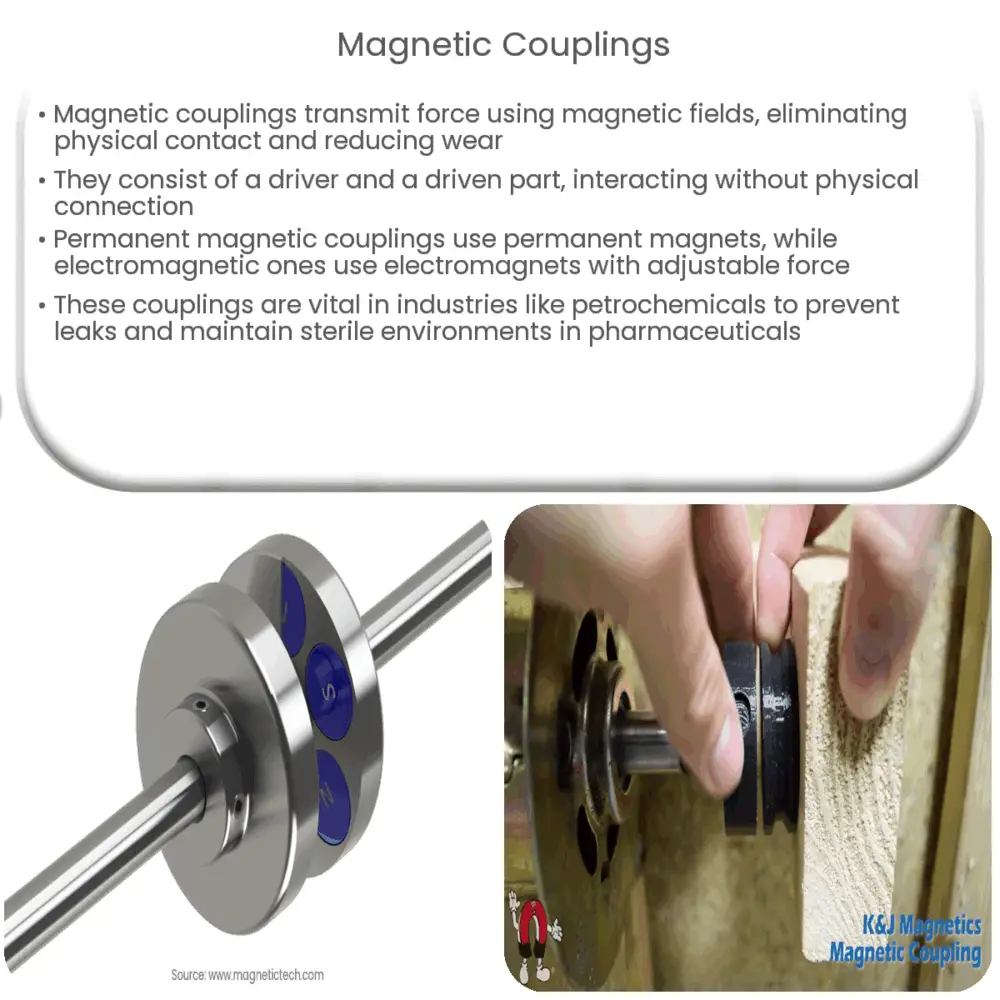

Magnetic couplings are an essential and fascinating area of mechanical engineering. They allow for the transmission of force through magnetic fields, thus eliminating the need for physical contact between moving parts. This ensures a nearly frictionless operation, leading to less wear and tear, and consequently, a longer life for the machinery involved.

How Magnetic Couplings Work

Magnetic couplings function based on the fundamental principles of magnetism. In simple terms, each coupling consists of two parts: the driver and the driven. The driver is the part connected to the power source, while the driven part is connected to the device that needs the power. These two parts interact via magnetic fields, allowing for the transmission of torque or force without any physical connection.

Types of Magnetic Couplings

- Permanent Magnetic Couplings: These couplings utilize permanent magnets to transmit force. They are maintenance-free and have a high level of efficiency, which makes them suitable for various applications where constant speed is required.

- Electromagnetic Couplings: As the name suggests, these couplings use electromagnets to transmit force. Their significant advantage is the ability to control the amount of force transmitted by regulating the current supplied to the electromagnet.

Applications of Magnetic Couplings

Magnetic couplings find wide applications across various industries. Due to their non-contact nature, they are highly sought after in sectors where contamination due to leakage or sealing failure could be catastrophic. Some notable examples include:

- Petrochemical industry: In petrochemical applications, magnetic couplings can be used in pumps and agitators to prevent leakage of harmful or volatile substances.

- Pharmaceutical industry: Here, they are used in mixers and pumps to ensure the integrity of sterile environments.

In the second part of this article, we’ll delve deeper into the advantages and potential challenges of using magnetic couplings, along with more detailed applications and the future trends in this field. Stay tuned!

Advantages of Magnetic Couplings

There are many benefits to using magnetic couplings in industrial machinery and devices. One major advantage is their ability to transmit force without physical contact, which results in reduced friction and heat, therefore extending the lifespan of the machinery. They also minimize the need for maintenance, as there are no wearing parts to replace.

Another significant benefit is their ability to act as a mechanical fuse. In cases of torque overload, the magnetic field simply decouples, preventing potential damage to expensive machinery components. Once the overload is cleared, the coupling will automatically re-engage.

Potential Challenges

While magnetic couplings offer many benefits, they also come with some challenges. First, there is a limit to the amount of force they can transmit, which is dependent on the strength of the magnetic field. Thus, they might not be suitable for applications that require extremely high torque. Second, they can be sensitive to high temperatures, which can weaken the magnetic field.

Future Trends in Magnetic Couplings

As technology continues to evolve, the future for magnetic couplings looks promising. The development of stronger and more heat-resistant magnets could extend their applicability to a wider range of industrial scenarios. In addition, advancements in design and manufacturing technologies may further improve their efficiency and reliability.

Conclusion

In conclusion, magnetic couplings are a remarkable technological innovation that holds significant potential in various industries. Their ability to transmit force without physical contact can reduce maintenance needs, improve equipment lifespan, and enhance safety, especially in industries dealing with hazardous or sterile materials. Despite the challenges, ongoing advancements promise to further broaden their applicability and efficacy. Their continued integration into new and existing technologies is likely to reshape how we approach mechanical design, and by extension, industrial processes in the future.