Explore the world of magnetic clutches, their working principle, benefits, limitations, applications, and future trends in this comprehensive article.

Introduction to Magnetic Clutches

Magnetic clutches are innovative devices that play a critical role in various industries and machinery. The clutch’s principle of operation is based on magnetic fields and how they interact with metallic objects. So, what exactly is a magnetic clutch, and how does it work? This article will delve into these questions to give you a better understanding.

Understanding Magnetic Clutches

A magnetic clutch is a special type of clutch that uses magnetic forces to control the transmission of power between the input and output shafts. Unlike other types of clutches that rely on mechanical or hydraulic forces, the magnetic clutch operates based on electromagnetic principles. This ensures smoother and more controlled power transmission.

How Magnetic Clutches Work

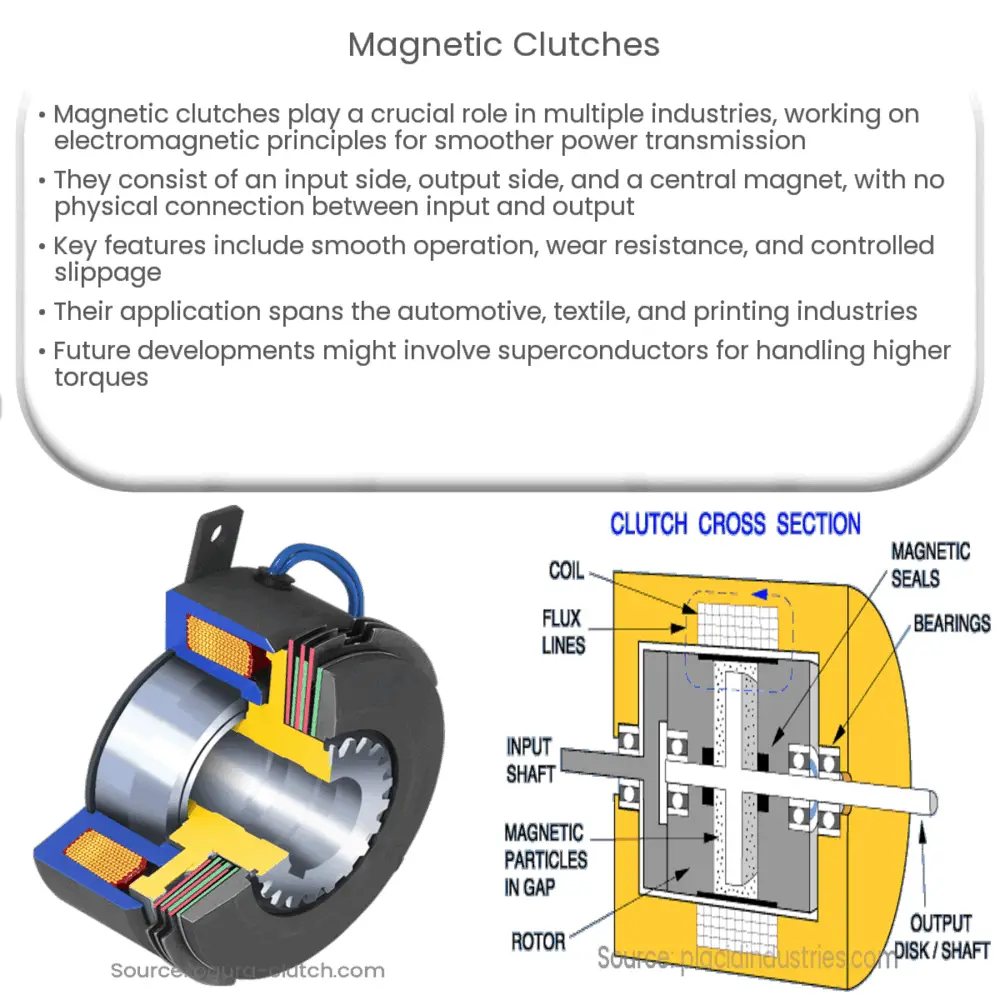

The operation of magnetic clutches revolves around three main components – the input side (drive side), the output side (driven side), and the magnet. The input and output sides are not physically connected. Instead, they are designed to be in very close proximity to each other. In the middle of these two components, the magnet plays a crucial role.

The Role of the Magnet

The magnet in a magnetic clutch is the linchpin of the entire operation. When the magnet is not powered, there’s no magnetic field produced, and the input and output sides of the clutch do not interact, meaning there’s no power transfer. However, when power is supplied, a magnetic field is created. This field attracts the output side to the input side, causing them to rotate at the same speed, thereby transmitting power.

Key Features of Magnetic Clutches

- Smooth Operation: Since the operation of a magnetic clutch relies on magnetic forces, the transmission of power between the input and output sides is usually very smooth.

- Wear Resistance: Magnetic clutches do not involve direct physical contact between the input and output sides, reducing wear and tear.

- Controlled Slippage: Magnetic clutches allow for controlled slippage, which can be beneficial in certain applications where a small amount of slip is required for a smoother operation.

Indeed, the use of magnetic clutches has revolutionized various industries. From automotive to industrial machinery, they offer a robust solution to power transmission challenges. Their inherent characteristics, such as smoother operation and resistance to wear and tear, make them preferable over their mechanical counterparts.

However, like any other technology, they come with their own set of drawbacks. In the next part of this article, we will explore these limitations, along with discussing potential applications and future trends in the field of magnetic clutches.

Limitations of Magnetic Clutches

While magnetic clutches offer many benefits, they are not without their drawbacks. One major downside is their dependency on a power source. If the power supply is interrupted, the clutch will disengage, potentially disrupting the operation of the machinery. Additionally, these clutches are not suitable for applications that require high torque transmission, as the magnetic field might not be able to handle it.

Applications of Magnetic Clutches

Magnetic clutches have found their place in various industrial applications. These include:

- Automotive industry: They are used in the cooling systems of cars, specifically in the radiator fan. The clutch allows the fan to engage and disengage as needed, reducing power consumption and noise.

- Textile industry: The textile industry uses magnetic clutches to control winding mechanisms in various machines, thereby ensuring uniform tension and reducing the chance of yarn breakage.

- Printing industry: In printing machinery, these clutches are used to control the rolling and unrolling of paper, which needs to be done at a precise speed to prevent paper jams or tears.

Future Trends in Magnetic Clutches

With advancements in technology, magnetic clutches are expected to see considerable improvements in the coming years. Researchers are exploring the use of superconductors to create more powerful magnetic fields. This could potentially allow these clutches to handle higher torque applications, extending their utility.

Conclusion

In conclusion, magnetic clutches, with their smooth operation and wear-resistant characteristics, are an invaluable asset in many industrial applications. Despite their limitations, they have proved their worth in various scenarios where precise control and smooth power transmission are paramount. As technology continues to evolve, we can expect further advancements in this field that will enhance the capabilities of these fascinating devices. It’s clear that the future of power transmission and control, in many respects, will be influenced by the continued evolution and improvement of magnetic clutches.