Explore the Insulated-Gate Bipolar Transistor (IGBT): its structure, operation, applications, and future in power electronics.

Introduction to Insulated-Gate Bipolar Transistor (IGBT)

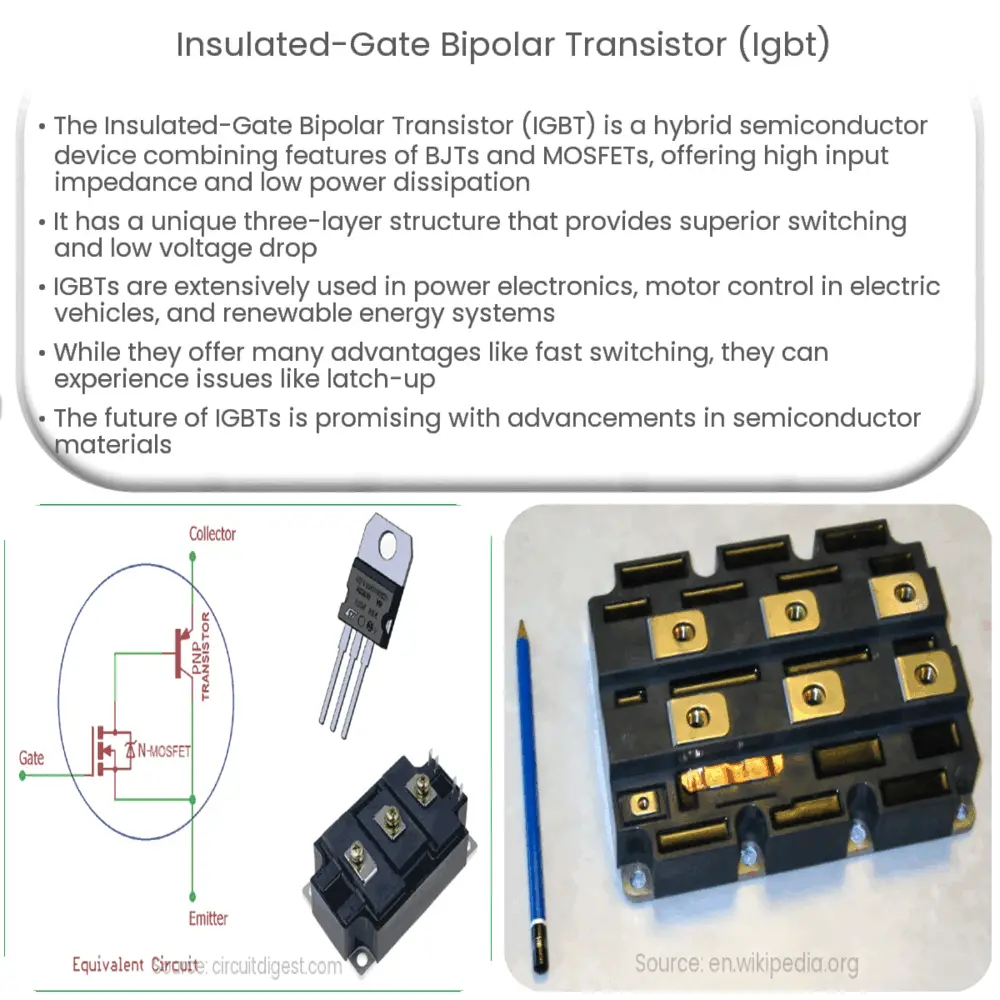

The Insulated-Gate Bipolar Transistor (IGBT) is a power electronic semiconductor device that has revolutionized the field of electronics. It possesses the virtues of both Bipolar Junction Transistors (BJTs) and Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) to create an optimal hybrid device with high input impedance and low on-state power dissipation.

The Structure of an IGBT

An IGBT is a three-layer, four-terminal device that combines an isolated gate FET for the control input and a bipolar power transistor as a switch in a single device. The main terminals, termed as the Collector (C) and the Emitter (E), are associated with the bipolar transistor, whereas the Gate (G) terminal is associated with the MOSFET. This unique structure allows for the superior switching capabilities and low on-state voltage drop.

Operation of an IGBT

An IGBT operates in three different states: the cut-off state, active state, and saturation state. Each of these states depends on the voltages applied to the terminals. In the cut-off state, no current flows through the device. The active state is where the device allows current to flow, and the saturation state is where the device reaches its maximum current capability.

- Cut-off State: When the Gate-Emitter voltage is less than the threshold voltage, the device is in its cut-off state. No conduction occurs in this state.

- Active State: When the Gate-Emitter voltage exceeds the threshold voltage, but the Collector-Emitter voltage is less than the Gate-Emitter voltage, the device transitions into its active state, and current begins to flow.

- Saturation State: The IGBT is in its saturation state when both the Gate-Emitter voltage is higher than the threshold voltage, and the Collector-Emitter voltage is higher than the Gate-Emitter voltage. In this state, the device conducts maximum current.

Applications of IGBTs

IGBTs are found in a myriad of applications due to their superior performance characteristics. They are particularly useful in high power applications where efficiency and fast switching are crucial.

- IGBTs are used extensively in power electronics, particularly in inverters and converters, due to their ability to efficiently switch on and off at high voltages and currents.

- In the automotive industry, they are used in electric and hybrid vehicles for motor control and battery management.

- IGBTs are also prevalent in the renewable energy sector, specifically in solar inverters and wind power converters, where they help to maximize energy efficiency.

Advantages and Disadvantages of IGBTs

Like all electronic components, IGBTs come with their own set of advantages and disadvantages which make them more suited for certain applications.

- Advantages: The primary advantage of IGBTs lies in their high input impedance, which allows for easy driving of signals. They also offer low on-state voltage drop, which leads to minimal power dissipation during operation. Additionally, their fast switching speed makes them ideal for high frequency applications.

- Disadvantages: On the flip side, IGBTs are susceptible to latch-up, a condition where the device continues to conduct even after the gate voltage is removed. They also have a slower turn-off time compared to other devices, which can limit their effectiveness in certain high frequency applications.

Future of IGBTs

The future of IGBTs looks promising as advances in semiconductor technology continue to improve their performance characteristics. With a trend towards electric vehicles and renewable energy, the demand for efficient and high-performing power electronic devices such as IGBTs is expected to rise. Furthermore, ongoing research into new materials like Silicon Carbide (SiC) and Gallium Nitride (GaN) promises to further enhance the capabilities of IGBTs.

Conclusion

In conclusion, Insulated-Gate Bipolar Transistors (IGBTs) are a vital component in the world of power electronics. Their unique structure and operating characteristics make them an invaluable tool for a wide range of applications, especially those requiring high power and efficiency. Despite their shortcomings, the future of IGBTs is bright, with ongoing technological advancements promising to further enhance their performance and expand their utility in emerging fields such as renewable energy and electric vehicles.