Explore the principles, applications, advantages, and future of Inductive Speed Sensors in our comprehensive guide.

Introduction to Inductive Speed Sensors

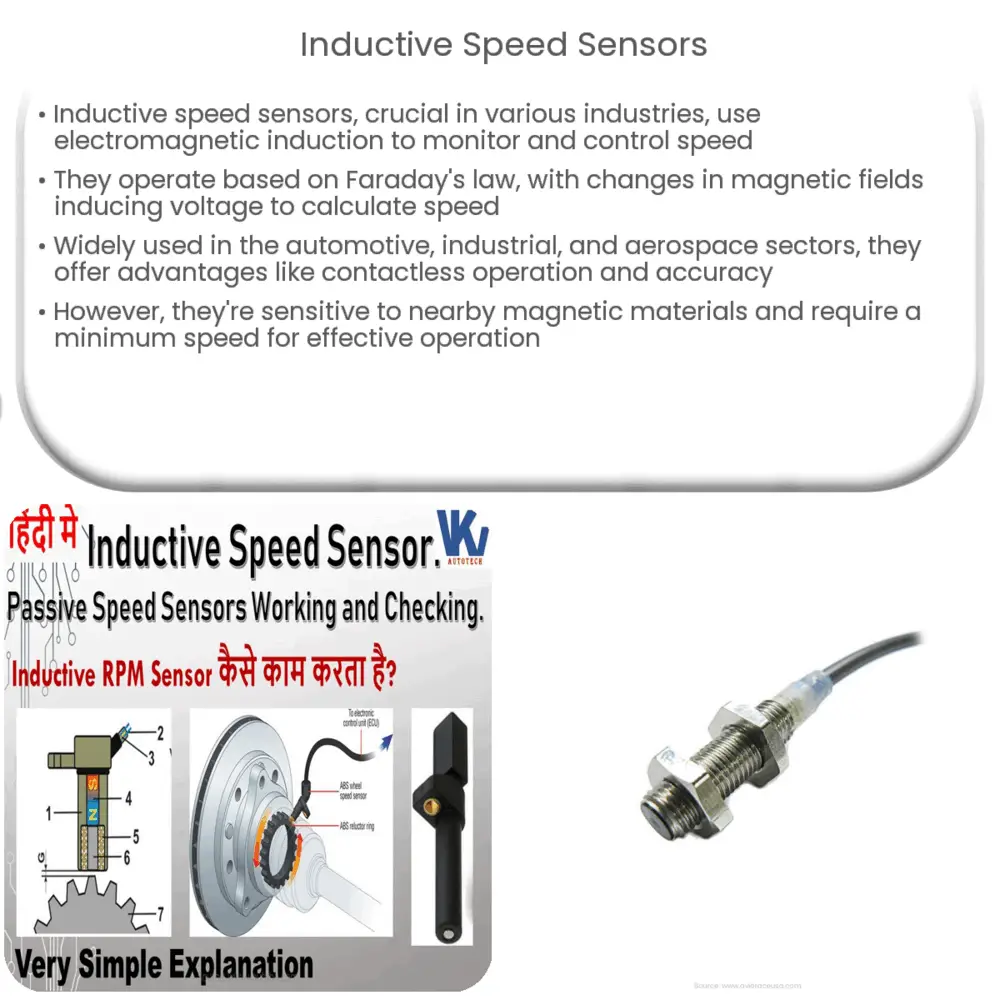

Inductive speed sensors, also known as variable reluctance sensors, are crucial components in various industries. Their ability to monitor and control speed in machinery and automotive systems make them indispensable. They are non-contact sensors, which use the principle of electromagnetic induction to detect changes in position and speed.

Working Principle

The primary mechanism of operation of inductive speed sensors is centered around Faraday’s law of electromagnetic induction. They consist of a wire coil wound around a magnetic core, and a target wheel, often referred to as a ‘gear tooth’ or ‘reluctor.’

As the target wheel rotates, it alternately makes and breaks the magnetic field created by the sensor’s coil. This change in the magnetic field induces a voltage in the coil. The induced voltage peaks when the tooth is closest to the sensor, providing a signal that can be used to calculate speed.

Applications of Inductive Speed Sensors

- Automotive Industry: They are heavily used in ABS systems to measure the speed of each wheel, thereby enabling better control and prevention of wheel lock-up.

- Industrial Automation: Here, these sensors help in maintaining the speed of conveyor belts, drills, and other high-speed machinery for optimal performance and safety.

- Aerospace: In this field, they are used for monitoring and controlling the speed of turbines, propellers, and other moving parts.

Advantages and Limitations

Inductive speed sensors boast of multiple advantages like being contactless and therefore non-wearing, capable of functioning in harsh environments, and being highly accurate in their measurements. However, they do have certain limitations such as being sensitive to magnetic materials nearby and requiring a certain minimum speed to operate effectively.

Types of Inductive Speed Sensors

The two main types of inductive speed sensors are active and passive. Active sensors, also known as magneto-resistive sensors, need a power supply and give a digital output. On the other hand, passive sensors do not require an external power source and give an analog output. Each type is beneficial for different situations, with the choice often depending on the specific application’s requirements.

Selection Criteria for Inductive Speed Sensors

When choosing an inductive speed sensor, several factors must be taken into consideration. These include the environment in which the sensor will be installed, the nature of the target (such as its material and shape), the sensor’s operational speed range, and the type of output signal required.

Improvements and Innovations

Over the years, there have been significant improvements in inductive speed sensor technology. Innovations have led to smaller, more compact designs, enhanced performance, and greater resistance to environmental factors. Digital signal processing technology has improved the accuracy and reliability of these sensors, especially in situations with low-speed operations.

Future of Inductive Speed Sensors

As the need for precise speed control and monitoring grows in various sectors, the demand for inductive speed sensors is expected to rise. Moreover, ongoing advancements in technology and increasing applications in areas like electric vehicles, drones, and smart factories will continue to drive the evolution and development of these sensors.

Conclusion

In conclusion, inductive speed sensors, with their ability to accurately detect and monitor speed, have become integral to many industries. They showcase the application of a fundamental principle of physics – electromagnetic induction, to solve real-world problems. Though they have their limitations, ongoing innovations and improvements continue to expand their scope and efficiency. From our vehicles to factory machinery, and beyond, these sensors play a critical role in our daily lives, often without us even realizing it. As we move towards an increasingly automated future, inductive speed sensors are set to become even more pivotal in facilitating and enhancing these advancements.