Explore the importance of Inductive Power Factor Correction Devices in improving power system efficiency and reducing energy costs.

Understanding Power Factor and Its Significance

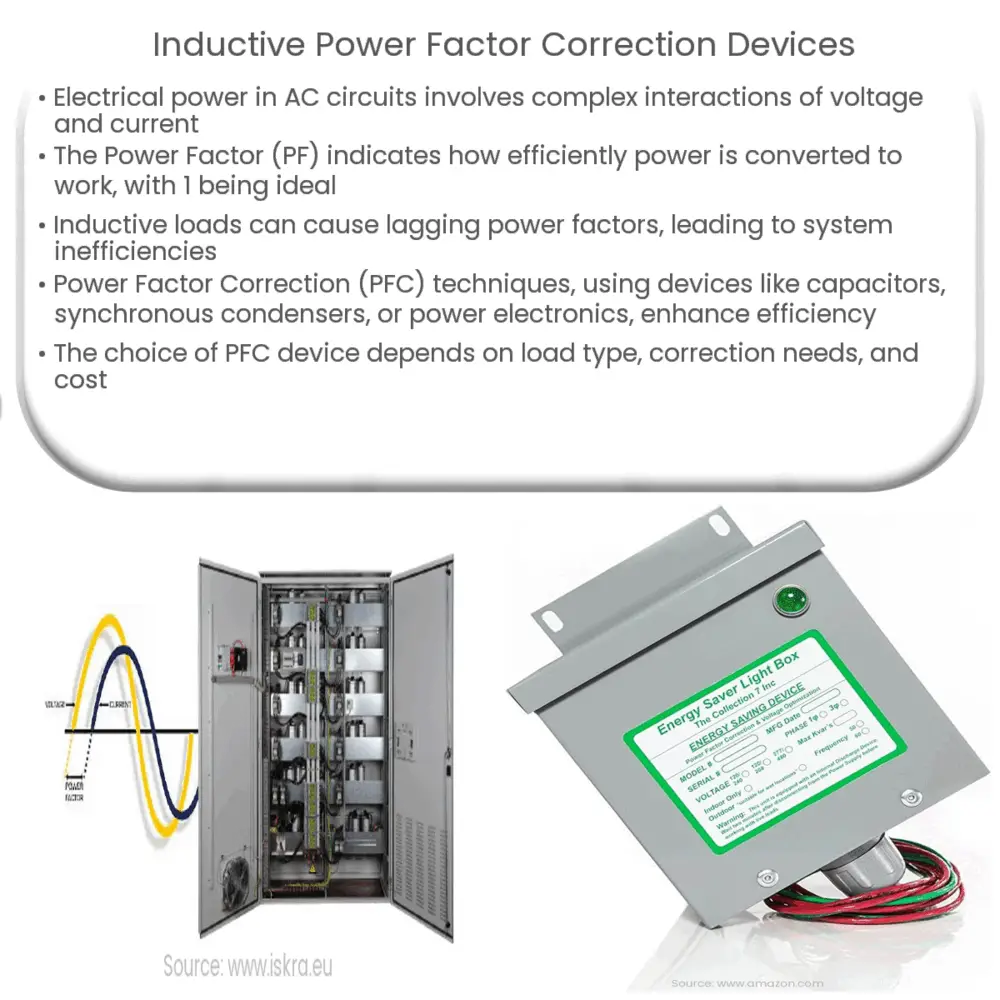

The electrical power that flows in an alternating current (AC) circuit is a complex interaction of voltage and current waveforms. It is essential to comprehend this interaction to optimize the efficiency of electrical systems. One crucial concept in this context is the Power Factor.

Power Factor (PF) is a ratio that reflects how efficiently electrical power is converted into useful work output. It is defined as the cosine of the phase angle between the current and voltage in an AC circuit. The Power Factor ranges between 0 and 1, with a value of 1 being ideal, implying that all the power supplied is being efficiently used.

The Need for Power Factor Correction

Many electrical devices, especially those with inductive loads such as motors, transformers, and inductive heaters, can cause a lagging power factor. This means that the current waveform lags behind the voltage waveform, leading to inefficiencies in the power system. These inefficiencies may manifest as increased power loss, reduced power system capacity, and higher energy costs.

Here, Power Factor Correction (PFC) comes into the picture. PFC is a technique used to improve the power factor and thereby increase the efficiency of power systems. The goal of PFC is to bring the power factor as close to 1 as possible, which can be achieved using several methods, including using capacitors, synchronous condensers, or power electronics-based systems.

Inductive Power Factor Correction Devices

Inductive Power Factor Correction Devices are an essential component of PFC technology. These devices work to counteract the effects of inductive loads, which typically cause the power factor to lag.

Understanding the Working of Inductive Power Factor Correction Devices

In the case of capacitors, they are installed parallel to the inductive load. When the load starts drawing current from the source, the capacitors supply a leading current which offsets the lagging inductive current. This brings the power factor closer to unity, thereby improving the efficiency of the power system.

Synchronous condensers, on the other hand, operate by varying their field excitation. This changes the amount of reactive power they absorb or generate, thereby influencing the power factor. They can be effectively used to correct both leading and lagging power factors, making them quite flexible for power factor correction tasks.

Power Electronics-Based Systems or Active Power Factor Correction (APFC) systems are dynamic in nature. They use advanced control techniques to continuously adjust the power factor according to the load requirement. While they offer the best performance in terms of power factor correction, their high cost can be a limiting factor for some applications.

Considerations for Selecting Inductive Power Factor Correction Devices

The choice of Inductive Power Factor Correction Device depends on several factors including the nature of the load, the required correction level, cost considerations, and the specific requirements of the power system. For instance, capacitors are a cost-effective solution for systems with stable loads, while APFC systems are ideal for systems with rapidly varying loads.

Conclusion

Inductive Power Factor Correction Devices play a critical role in enhancing the efficiency of power systems and reducing energy costs. With the help of capacitors, synchronous condensers, or power electronics-based systems, these devices help correct the lagging power factor caused by inductive loads. The choice of device depends on various factors, including the type of load, required correction, and cost. Ultimately, understanding and employing these devices appropriately is key to optimizing the performance and efficiency of power systems.