Explore the world of Insulated Gate Bipolar Transistors (IGBTs), their structure, benefits, applications, and future perspectives in power electronics.

Understanding IGBTs (Insulated Gate Bipolar Transistors)

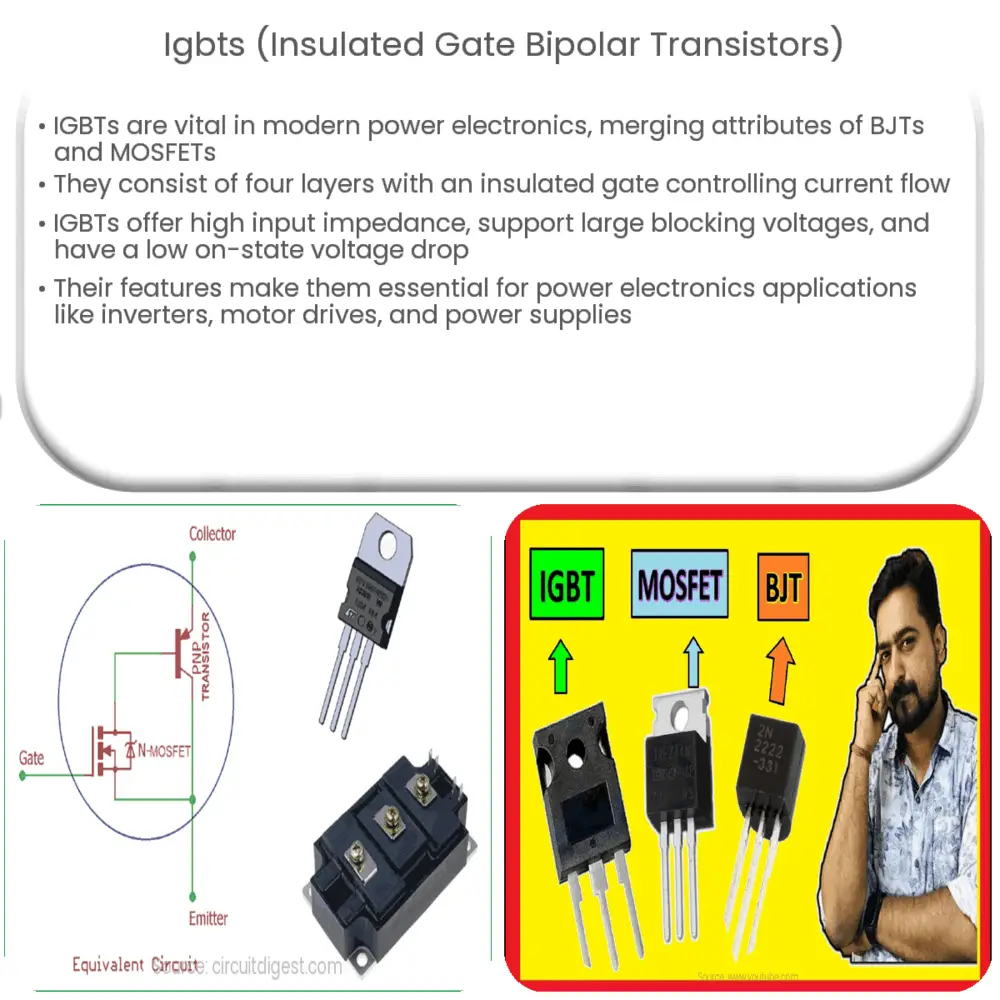

Insulated Gate Bipolar Transistors (IGBTs) are critical components in today’s world of power electronics. As hybrid devices, they combine the attributes of Bipolar Junction Transistors (BJTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), providing a robust and efficient way to manage electrical power.

The Structure and Operation of IGBTs

At a fundamental level, an IGBT consists of four alternating layers of p-type and n-type semiconductor material, akin to a BJT. However, it differs in the inclusion of an insulated gate structure, similar to a MOSFET. This gate is used to control the device’s operation. When a voltage is applied to the gate, it influences the conductivity of the device, turning the current flow on or off.

- 1 The Emitter: This is where the majority carriers (electrons for n-type, holes for p-type) are injected into the transistor.

- 2 The Base: It plays a crucial role in regulating the flow of carriers from the emitter.

- 3 The Collector: It is the terminal that collects and outputs the majority carriers.

- 4 The Gate: It controls the current flow through the device by modulating the conductivity between the emitter and collector.

Key Advantages of IGBTs

IGBTs bring several significant benefits to the realm of power electronics. Due to their unique combination of features, they bridge the gap between BJTs and MOSFETs.

- 1 High Input Impedance: IGBTs, like MOSFETs, have high input impedance. This trait reduces the power needed to drive them, making them easier and more efficient to control.

- 2 Large Blocking Voltage: Like BJTs, IGBTs can support high blocking voltages. This makes them well-suited for high voltage applications, such as power transmission and motor drives.

- 3 Low On-State Voltage Drop: The on-state voltage drop across an IGBT is lower compared to a BJT, making it more efficient in conducting power.

Together, these features make IGBTs an ideal choice for various applications in power electronics. They are particularly favored in devices and systems where high voltage, high current, and high switching frequency are paramount, such as inverters, electric vehicles, and power supplies.

Applications of IGBTs

Given their unique advantages, IGBTs find wide usage across a variety of domains:

- 1 Inverters: Inverters convert DC power to AC power. IGBTs, with their fast switching capability and high voltage handling, are extensively used in these systems.

- 2 Motor Drives: Electric motor drives require efficient and rapid switching of power. IGBTs serve this need well, particularly in the drives of electric vehicles and industrial machinery.

- 3 Power Supplies: In both switched-mode power supplies (SMPS) and Uninterruptible Power Supplies (UPS), IGBTs provide efficient and reliable power regulation and switching.

- 4 Induction Heating: IGBTs are well-suited to the high frequencies and high voltages needed in induction heating systems, such as those used in cooking appliances and industrial heating.

Future Perspectives

As the demand for efficient power electronics continues to grow, the development and improvement of IGBTs remain an active area of research. Novel structures and materials, such as silicon carbide (SiC) and gallium nitride (GaN), are being explored to improve the performance and efficiency of IGBTs. Furthermore, the rise of electric vehicles and renewable energy systems, which extensively utilize power electronics, will likely drive the continued innovation and adoption of IGBT technology.

Conclusion

In conclusion, IGBTs represent a fascinating combination of BJT and MOSFET technologies, offering a unique blend of high input impedance, high blocking voltage, and low on-state voltage drop. As such, they are integral components of many modern power electronics applications, from inverters and motor drives to power supplies and induction heating systems. With ongoing advancements and the rising demand for efficient power electronics, the role and importance of IGBTs in our electrified world are set to increase even further.